Modified kitchen waste grease lubricant for drilling fluid and preparation method thereof

A technology of waste oil and lubricant, which is applied in the field of modified kitchen waste oil lubricant for drilling fluid and its preparation, which can solve the problems of environmental pollution and cost, and achieve good biodegradability, improved lubrication effect, and low fluorescence level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

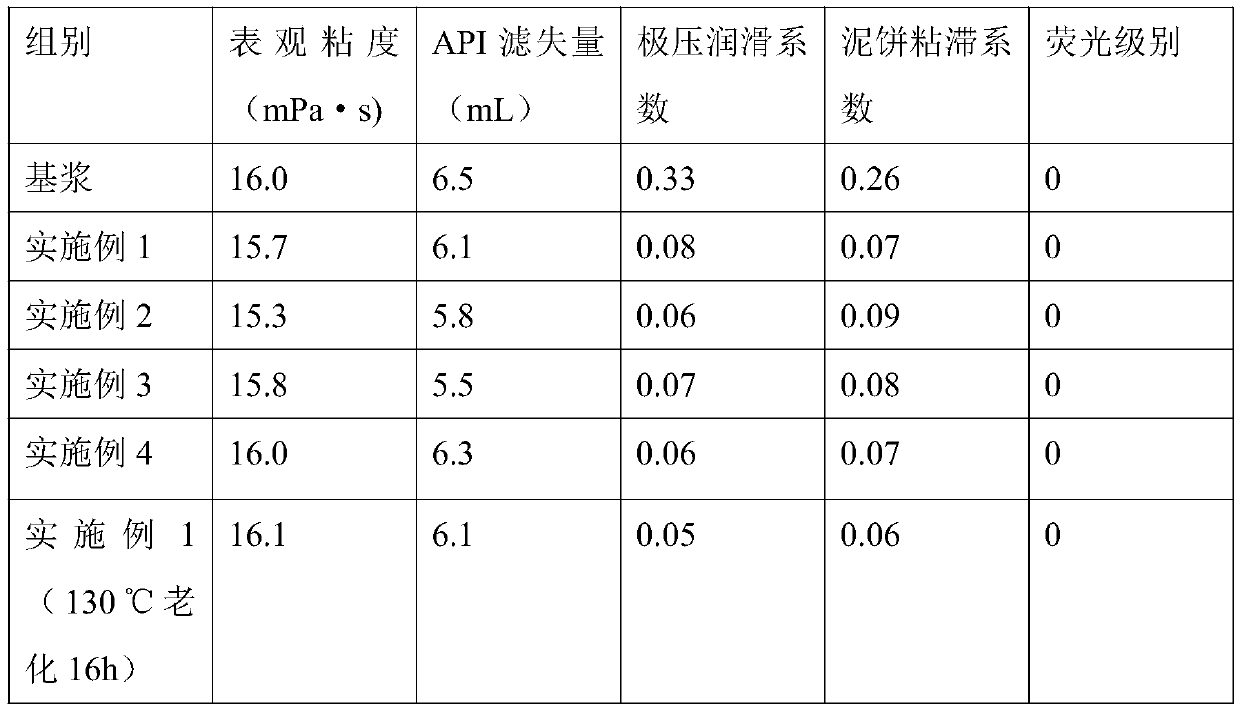

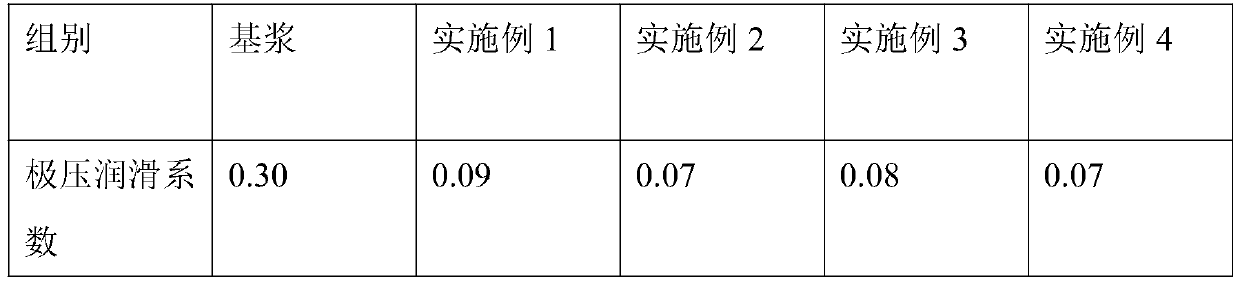

Examples

preparation example Construction

[0027] The present invention also provides a preparation method of a modified kitchen waste grease lubricant for drilling fluid, comprising the following steps:

[0028] (1) Weigh waste kitchen grease, place it in the first reaction kettle and gradually heat it up to 70°C-90°C, slowly add 30% aqueous sodium hydroxide solution to it under constant stirring, and continue stirring until the first reaction The solution in the kettle has no obvious stratification phenomenon, and the reaction ends at this moment, and the heating is stopped;

[0029] (2) Slowly drip saturated sodium chloride solution while hot in the above reaction solution and constantly stir, solids are separated out in the reaction solution, until no new solids are separated out, stop dripping saturated sodium chloride solution, and the The reaction liquid is filtered, the liquid part is removed, and the solid matter is collected for cooling and drying;

[0030] (3) Place the above-mentioned dried solid matter in...

Embodiment 1

[0033] A modified kitchen waste grease lubricant for drilling fluid. In parts by weight, the raw materials of the lubricant include 60 parts of kitchen waste oil, 10 parts of 30% sodium hydroxide aqueous solution, 10 parts of oleum, phosphoric acid 1 part of tricresyl ester, 0.5 part of zinc dialkyldithiophosphate, a total of 0.2 parts of ultraviolet absorber UV-9, ultraviolet absorber UV-531 and ultraviolet absorber RMB, a total of 4 parts of sulfurized oleic acid and sulfurized cottonseed oil, 0.2 parts of sodium benzoate.

[0034] As a phosphorus-containing anti-wear agent, tricresyl phosphate can reduce wear, improve the load-carrying capacity and extreme pressure performance of lubricating oil, thereby improving the friction performance of lubricants. As an antioxidant, zinc dialkyl dithiophosphate can decompose hydroperoxides and capture a large number of free radicals generated by hydroperoxides, thereby limiting the oxidation reaction process and preventing lubricants ...

Embodiment 2

[0042] A modified kitchen waste grease lubricant for drilling fluid. In parts by weight, the raw materials of the lubricant include 90 parts of kitchen waste oil, 40 parts of 30% sodium hydroxide aqueous solution, 30 parts of fuming sulfuric acid, and 2 parts of di-n-butyl phosphate, 1 part of zinc diethyldithiocarbamate, 0.3 parts of light stabilizer GW-540 and light stabilizer 744, 6 parts of sulfurized olefin, sodium dehydroacetate and paraben A total of 0.3 parts.

[0043] As a phosphorus-containing anti-wear agent, di-n-butyl phosphite can reduce wear, improve the load-carrying capacity and extreme pressure performance of lubricating oil, thereby improving the friction performance of lubricants. As an antioxidant, zinc diethyldithiocarbamate can decompose hydroperoxides and capture a large number of free radicals generated by hydroperoxides, thereby limiting the oxidation reaction process and preventing lubrication agent is oxidized. Light stabilizer GW-540 and light st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com