Environment-friendly technology for directly coating oxidizable metal

It is an easy-to-oxidize metal and environmentally friendly technology. It is used in metal material coating technology, sputtering plating, ion implantation plating, etc. It can solve problems such as coating limitations, and achieve good corrosion resistance, reasonable design and good hydrophobicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

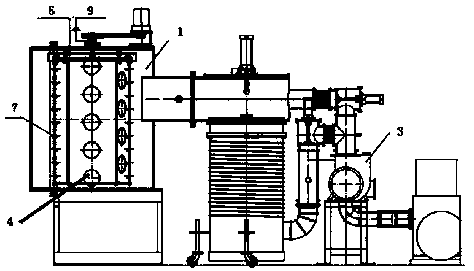

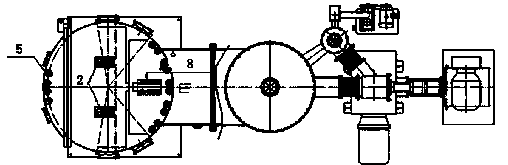

Image

Examples

Embodiment 1

[0020] A process of direct coating on easy-to-oxidize metals by using HIPIMS sputtering metallic glass combined with multi-arc ion plating:

[0021] 1. Take the copper material and carry out water-based degreasing cleaning first, and then dry it with cold air after cleaning;

[0022] 2. Put it into the vacuum coating equipment and start pumping. When the pressure is less than 3 Pa, turn on the heating and bake at 150 degrees; continue pumping after 30 minutes, and start after the basic vacuum pressure is lower than 5*10-3 Pa. The following process;

[0023] 3. When the argon gas vacuum reaches 1-2Pa, the bias voltage is turned on, and the voltage is gradually increased from 450V to 1000V, and the surface is cleaned by ion bombardment. The total time is 15-20 minutes, after which the bias voltage is turned off;

[0024] 4. Introduce argon gas 2-3 *10-1Pa, turn on the bias voltage, set 400-450V, turn on the HIPIMS sputtering power supply, the target can be zirconium-based meta...

Embodiment 2

[0028] A process using HIPIMS sputtering metallic glass combined with multi-arc ion plating to directly coat easily oxidizable metals (increase ion source):

[0029] 1. Take the copper material and carry out water-based degreasing cleaning first, and then dry it with cold air after cleaning;

[0030] 2. Put it into the vacuum coating equipment and start pumping. When the pressure is less than 3Pa, turn on the heating and bake at 150 degrees for 30 minutes, then continue pumping. After the basic vacuum pressure is lower than 5*10-3Pa, start the following process;

[0031] 3. When the argon gas vacuum reaches 1-2Pa, turn on the pressure, the voltage is gradually increased from 450V to 1000V, and the surface is cleaned by ion bombardment. Total time 15-20 minutes. Then turn off the bias;

[0032] 4. Turn off the argon gas, after the pressure is lower than the basic vacuum, add argon until the vacuum degree is 3-5*10-1Pa, turn on the ion source (Hall ion source, Kaufmann ion so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com