A three-dimensional porous fe@fe(oh) 3 Preparation method of oxygen evolution anode

A three-dimensional porous, anode technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problem of high price, achieve the effect of reducing precipitation overpotential, reducing oxygen evolution overpotential and total energy consumption, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

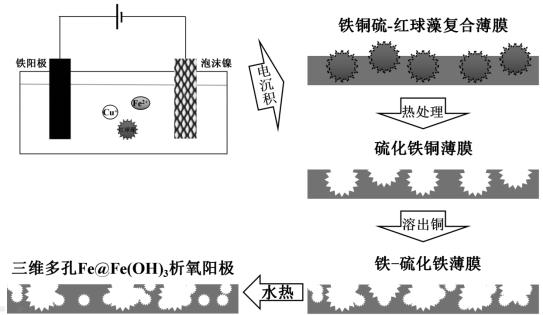

[0015] Specific embodiment one: a three-dimensional porous Fe@Fe(OH) of this embodiment 3 The preparation method of the oxygen-evolving anode is carried out according to the following steps:

[0016] (1) Broken Haematococcus: a. Freeze-dry the Haematococcus at -170 ℃ for 24~36 hours, take it out and thaw naturally; b. Repeat step a0~5 times to obtain the broken Haematococcus ;

[0017] (2) Preparation of composite electroplating solution: c. Weigh 0.5-8.0 g of Haematococcus treated in step (1), add it to 800 mL of deionized water, and stir ultrasonically at room temperature for 10-60 minutes to obtain solution A ; d. According to the concentration of malic acid is 5~25 g / L, the concentration of lactic acid is 5~35 mL / L, the concentration of hydrochloric acid is 1~25 mL / L, the concentration of ferrous chloride is 6~35g / L , the concentration of thiourea is 8~30 g / L, the concentration of cuprous chloride is 1~10 g / L, the concentration of potassium chloride is 30~100 g / L, malic ...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the current density adopted in e of step (3) is 0.8 ~ 6.0 A / dm 2 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the current density used in step (5) g is 0.2 ~ 2.5 A / dm 2 . Others are the same as in the first or second embodiment.

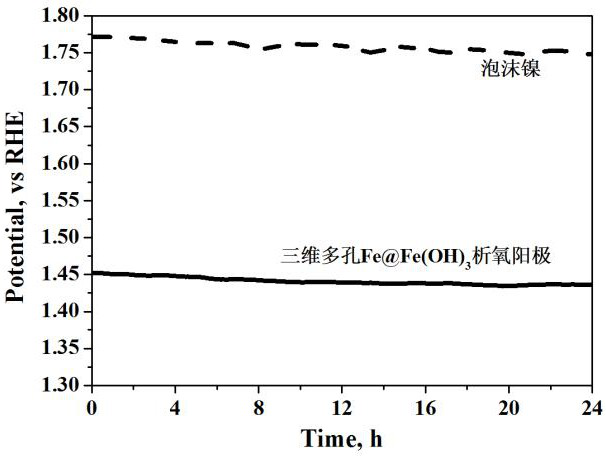

[0025] Verify beneficial effect of the present invention with following test:

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com