Preparation method of foam electrode for water electrolysis

A water electrolysis and electrode technology, which is applied in the field of water electrolysis to achieve the effects of reducing precipitation overpotential, reducing energy consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

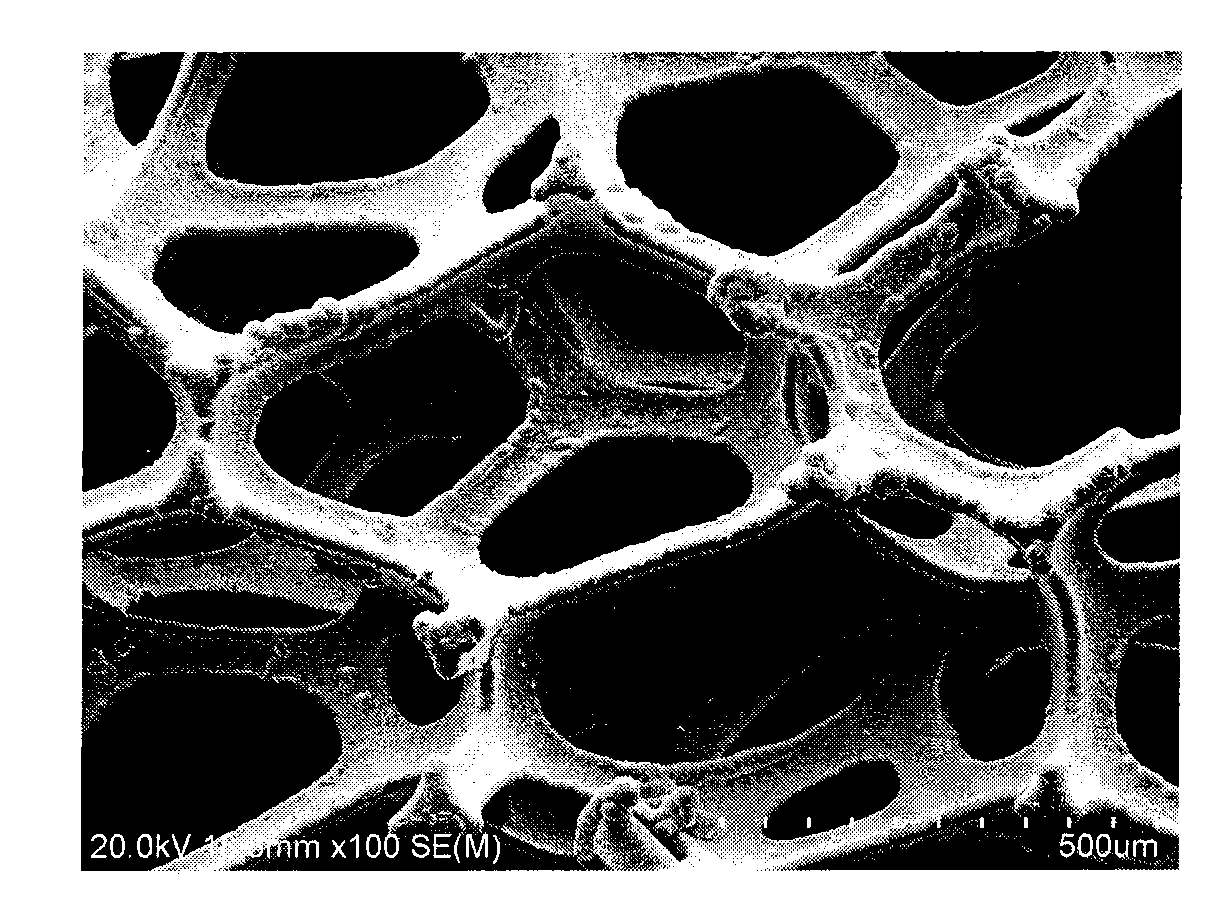

Image

Examples

Embodiment 1

[0024] A preparation method of a foam electrode for water electrolysis, the method steps are as follows,

[0025] (1) Choose a thickness of 2mm and a surface density of 400±10g / m 2 , the number of holes is 100-110PPI, and the nickel foam with a diameter of 150mm is used as the base material of the electrode material;

[0026] (2) Degreasing the surface of foamed nickel, put the foamed nickel into an oil tank with an ultrasonic generator, add acetone to completely soak the foamed nickel in it, turn on the power, take it out after ultrasonic cleaning for 5 minutes, and wait for the acetone to volatilize to obtain a clean surface. nickel foam;

[0027] (3) at room temperature, the foamed nickel and the conductive copper wire are clamped together with a clamp, and the foamed nickel is soaked in 10% sulfuric acid solution for 8 minutes to carry out surface activation treatment to the foamed nickel;

[0028] (4) Rinse the foamed nickel after activation with pure water, quickly imm...

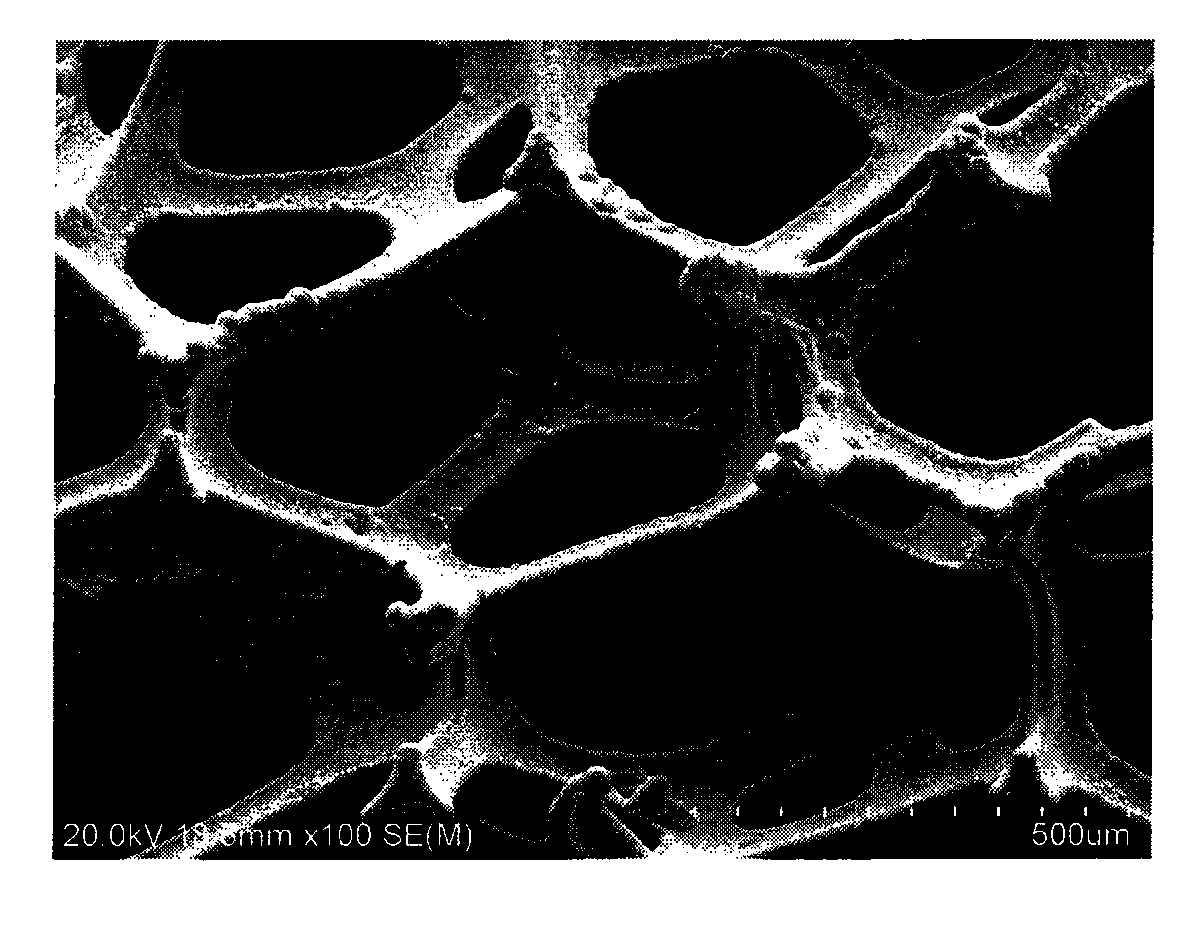

Embodiment 2

[0034] A preparation method of a foam electrode for water electrolysis, the method steps are as follows,

[0035] (1) Choose a thickness of 2mm and a surface density of 500±10g / m 2 , the number of holes is 70-80PPI, and the nickel foam with a diameter of 150mm is used as the base material of the electrode material;

[0036] (2) The surface of the foamed nickel is degreased, and the alkali boiling method is adopted. The lye formula is as follows: NaOH is 50g / L, NaOH is 50g / L, Na 2 CO 3 30g / L, Na 3 PO 4 20g / L, heat the lye to 80°C, and treat for 30 minutes to remove the oil and clean the surface of the nickel foam;

[0037] (3) At room temperature, the nickel foam and the conductive copper wire are clamped together with a clamp, and the nickel foam is soaked in a mixed solution of hydrochloric acid and sulfuric acid with a concentration of 10% sulfuric acid and a molar ratio of hydrochloric acid of 10:1 for 10 minutes. Nickel foam is used for surface activation treatment, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com