Catalytic filler for Fenton fluidized bed and preparation method thereof

A fluidized bed, catalytic technology, used in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc. The particle size cannot be adjusted, so as to achieve a uniform and good fluidized state, reduce the dosage of chemicals and operating costs, and ensure the effect of sewage treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of catalytic type filler for Fenton fluidized bed, described preparation method comprises the steps:

[0033] ① Dissolve equimolar amounts of ferric nitrate and manganese nitrate in water to obtain a metal salt solution with a metal ion concentration of 10mol / L, and add a solution with a specific surface area of 1000m 2 / g of activated carbon mixed, static impregnation 6h, Fe / Mn ion loading on the activated carbon is 5%, and then slowly dropwise added a polytetrafluoroethylene emulsion with a mass concentration of 60wt%, mixed, ultrasonic 60min, to obtain a viscous catalyst Slurry, wherein the weight ratio of metal salt, activated carbon and polytetrafluoroethylene is 0.3:6:1;

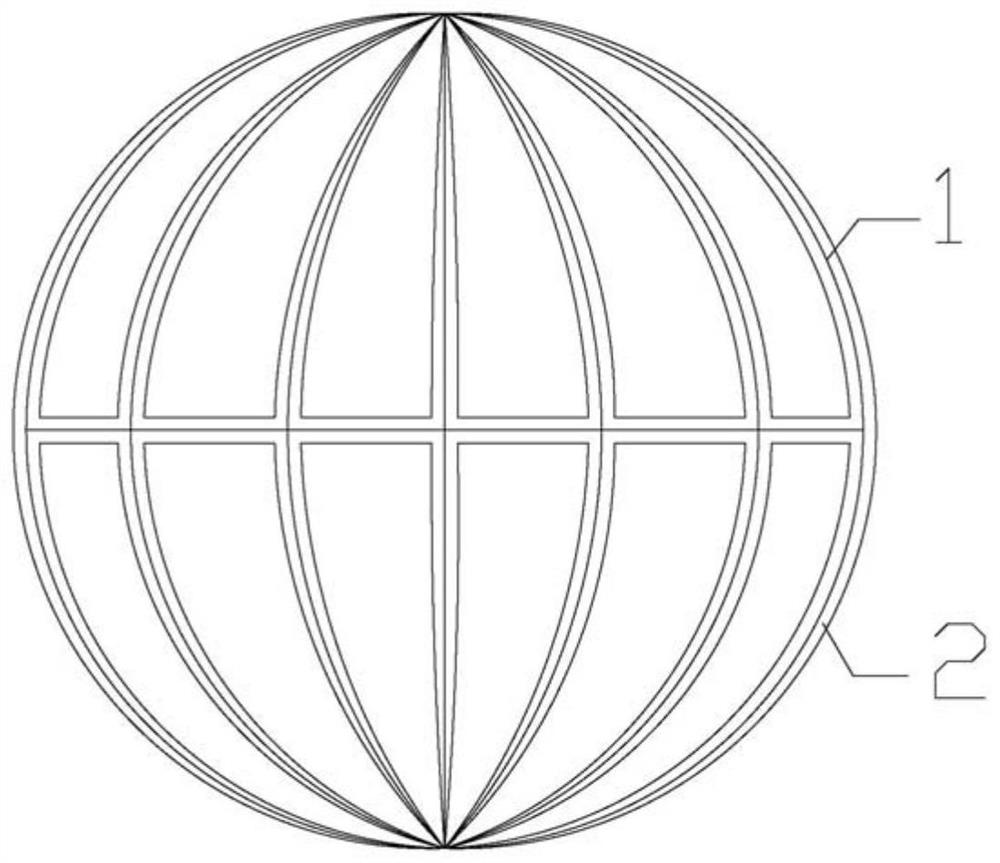

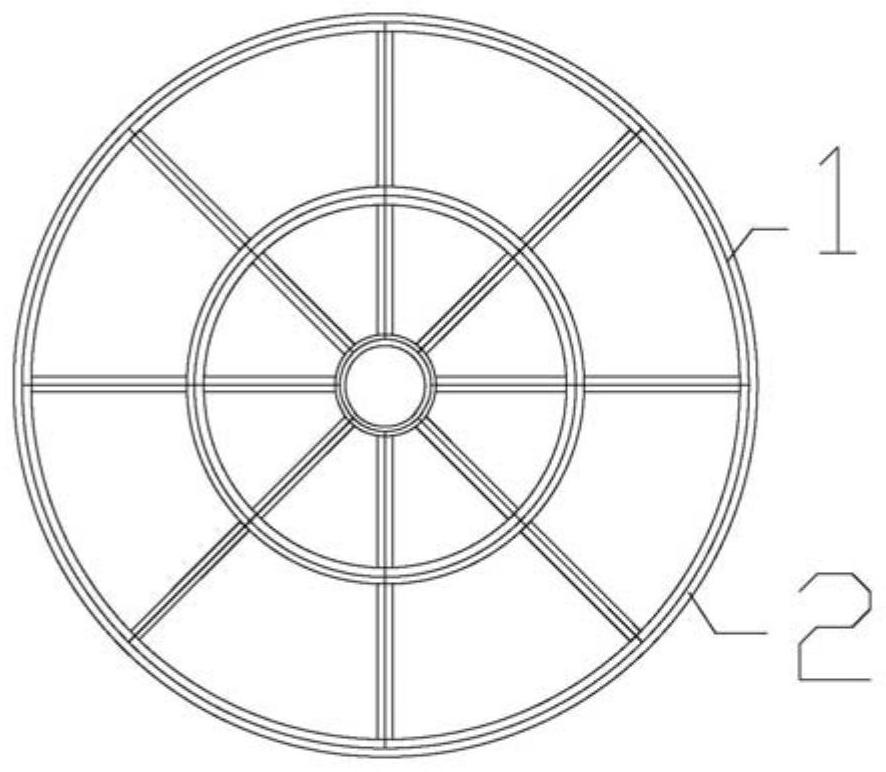

[0034] ②Immerse the polypropylene porous suspension filler with a particle size of 10mm in the viscous catalyst slurry, so that the surface of the polypropylene porous suspension filler is evenly wrapped with the viscous catalyst slurry, take it out, activate it in...

Embodiment 2

[0036] A kind of preparation method of catalytic type filler for Fenton fluidized bed, described preparation method comprises the steps:

[0037] ① Dissolve equimolar amounts of copper chloride and cobalt chloride in water to obtain a metal salt solution with a metal ion concentration of 20mol / L, and add a solution with a specific surface area of 2000m 2 / g of activated carbon, mix, stand and impregnate for 12h, the loading capacity of Cu / Co ions on the activated carbon is 20%, then slowly add polyvinylidene fluoride emulsion with a mass concentration of 30wt%, mix well, and ultrasonic 90min to obtain a viscous catalyst Slurry, wherein the weight ratio of metal salt, activated carbon and polyvinylidene fluoride is 1.2:6:1.5;

[0038] ② Immerse the polyamide porous suspension filler with a particle size of 50 mm in the viscous catalyst slurry, so that the surface of the polyamide porous suspension filler is evenly wrapped with the viscous catalyst slurry, take it out, activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com