Hydrogen circulating pump assembly

A technology of hydrogen circulation and assembly, applied in pumps, pump components, rotary piston pumps, etc., can solve the problems of hydrogen embrittlement and hydrogen corrosion, increase the oil content of the output hydrogen, leakage, etc., to prolong the service life, ensure the sealing effect, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

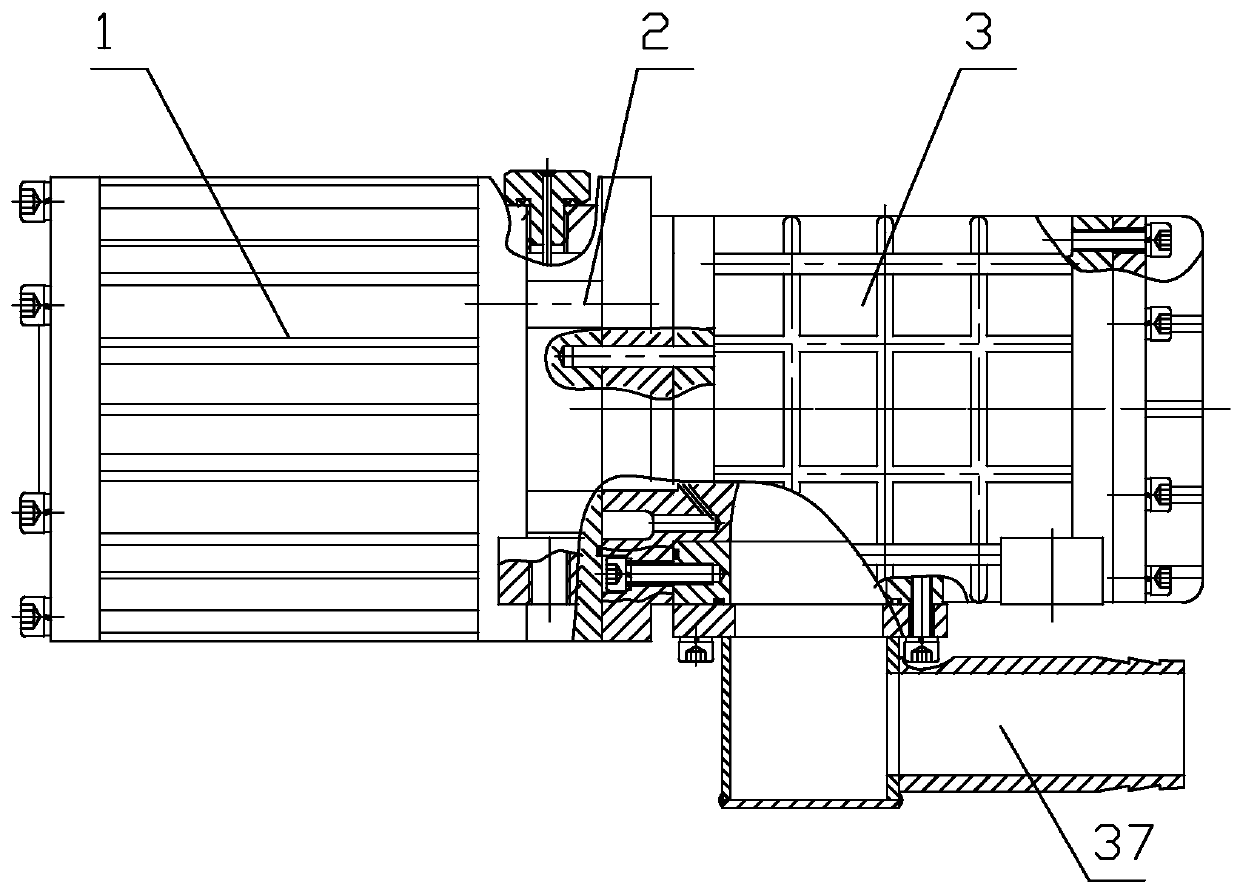

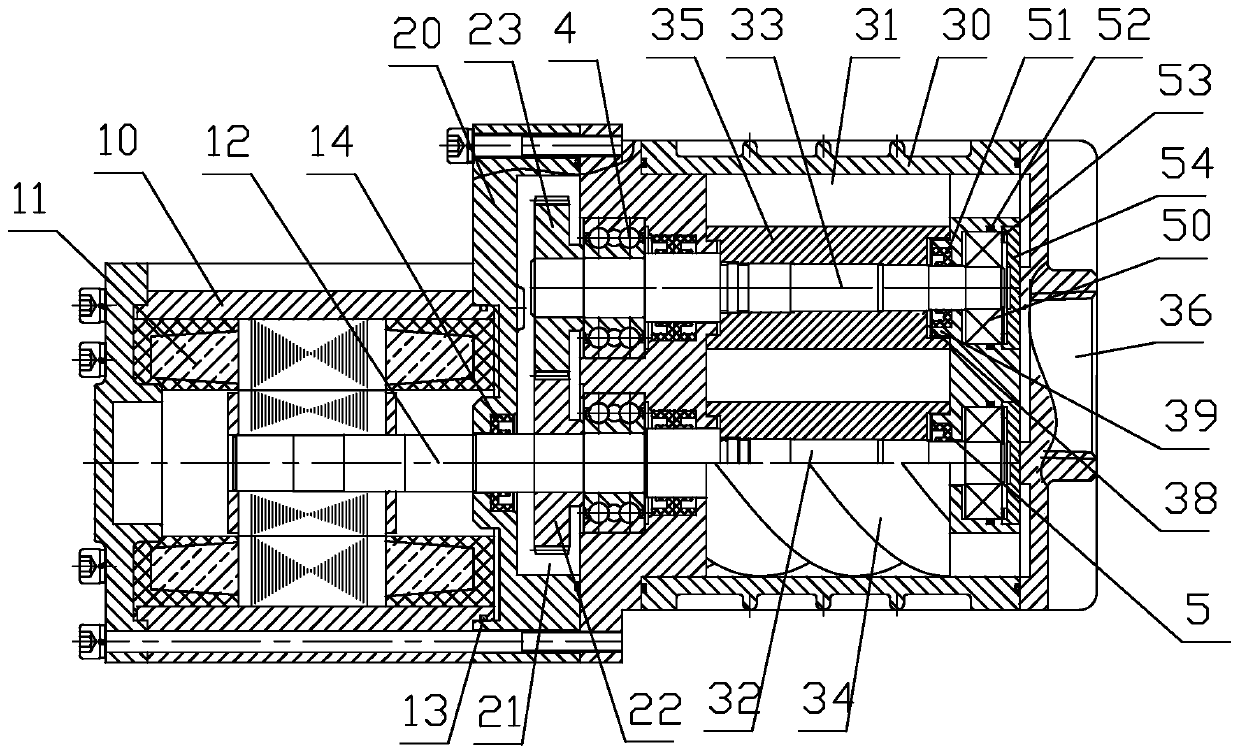

[0041] Such as figure 1 , 2 , 3, a hydrogen circulation pump assembly includes a motor part 1, a gear chamber part 2 and a supercharger part 3, the gear chamber part 2 is arranged between the motor part 1 and the supercharger part 3, and the motor Part 1 includes a motor housing 10, a motor 11, and a motor main shaft 12. The gear chamber part 2 includes a gear chamber housing 20, a gear chamber 21, a driving gear 22, and a driven gear 23. The supercharger part 3 includes Supercharger housing 30, compression chamber 31, male rotor shaft 32, female rotor shaft 33, male rotor 34, female rotor 35, air inlet 36 and air outlet 37,

[0042] Between the motor housing 10 and the gear chamber housing 20, between the gear chamber housing 20 and the supercharger housing 30, a sealing ring 13 is provided for sealing, so as to avoid hydrogen leakage from the gap;

[0043] A motor oil seal 14 is provided between the motor main shaft 12 and the gear chamber housing 20; a first sealing struc...

Embodiment 2

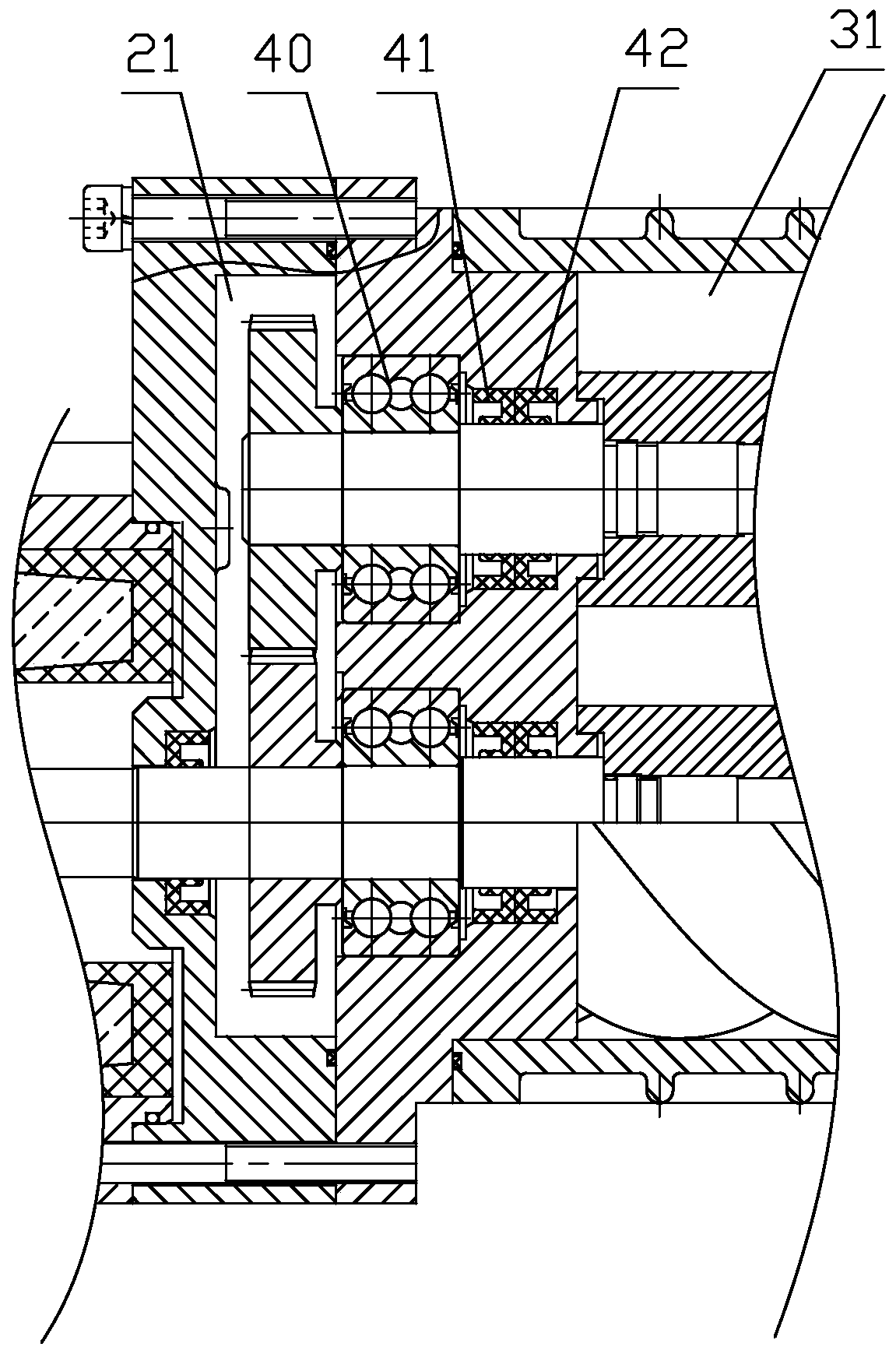

[0048] Such as figure 1 , 2 , 4, and 5, the difference between this embodiment and embodiment 1 is that the first sealing structure 4 includes a rolling bearing 43, an oil baffle 44, a first oil seal 41, a second oil seal 45 and an air seal 42 arranged in sequence, The rolling bearing 43 is close to the gear chamber 21, the air seal 42 is close to the compression chamber 31, an oil chamber 46 is provided between the first oil seal 41 and the oil baffle plate 44, and the oil chamber 46 passes through the oil provided in the gear chamber housing 20. The hole 47 communicates with the gear chamber 21 ; the oil baffle 44 is in interference fit with the gear chamber housing 20 , and the oil baffle 44 is in clearance fit with the male rotor shaft 32 and the female rotor shaft 33 . The second oil seal 45 and the air seal 42 are spaced apart, and the cavity between the second oil seal 45 and the air seal 42 communicates with the outside world through the vent hole 48 provided in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com