Vacuum cavity assembly for scattering experiment station

A technology of vacuum cavity and experimental station, which is applied in the direction of material analysis using radiation diffraction, material analysis using wave/particle radiation, and measuring devices, which can solve the problems of not being able to meet the experimental requirements at the same time, and achieve simple structure and easy maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

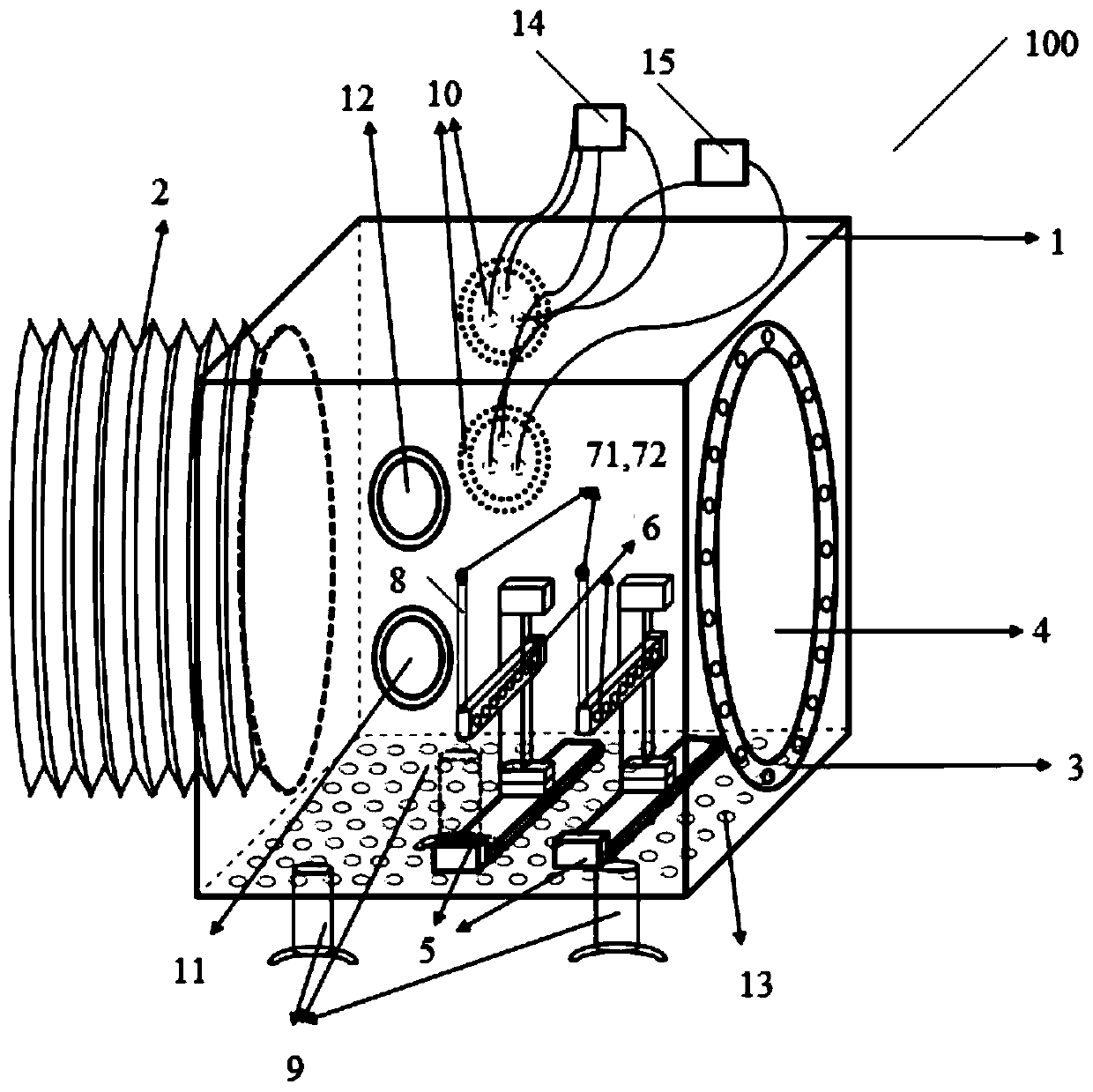

[0023] Such as figure 1 Shown is a vacuum chamber assembly 100 for a scattering experiment station according to a preferred embodiment of the present invention, comprising: a vacuum chamber body 1 having a receiving space; Tube 2, one end of the bellows 2 is connected to the front end of the vacuum chamber body 1 through a vacuum flange, and the other end is connected to the vacuum pipeline (not shown in the figure); the light-transmitting window 3 arranged at the rear end of the vacuum chamber body 1 is preferably Large-diameter light-transmitting window, the polyimide film 4 is fixed at 3 places of the light-transmitting window by flanges and sealing rings, and is used to maintain the vacuum degree of the vacuum chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com