In-situ optomagnetic non-orthogonal angle measurement method based on double-beam three-axis vector atom magnetometer

A technique for in-situ measurement of atomic magnetic strength, applied to three-component magnetometers, using magneto-optical equipment for magnetic field measurement, the size/direction of magnetic fields, etc., can solve the large measurement error of three-axis magnetometer, three-axis vector The atomic magnetometer is not strictly orthogonal, and cannot be suppressed by non-orthogonal angles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

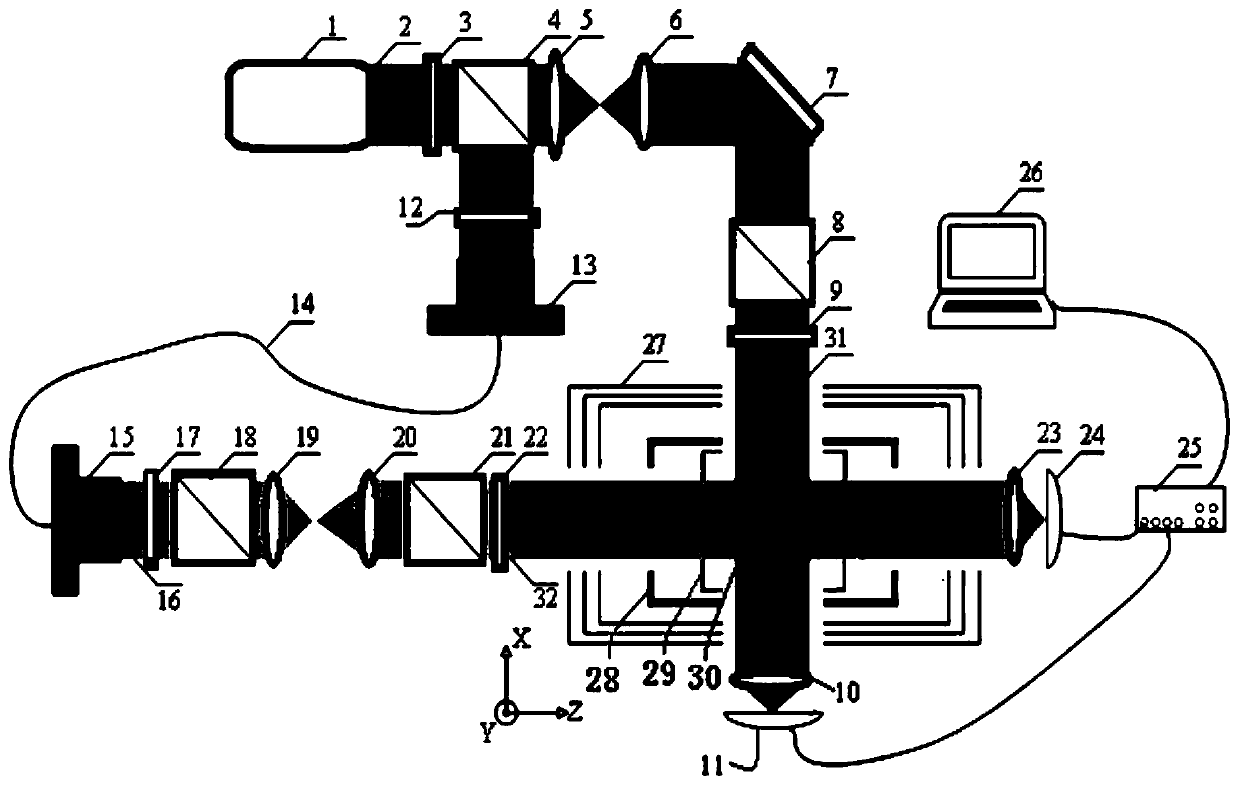

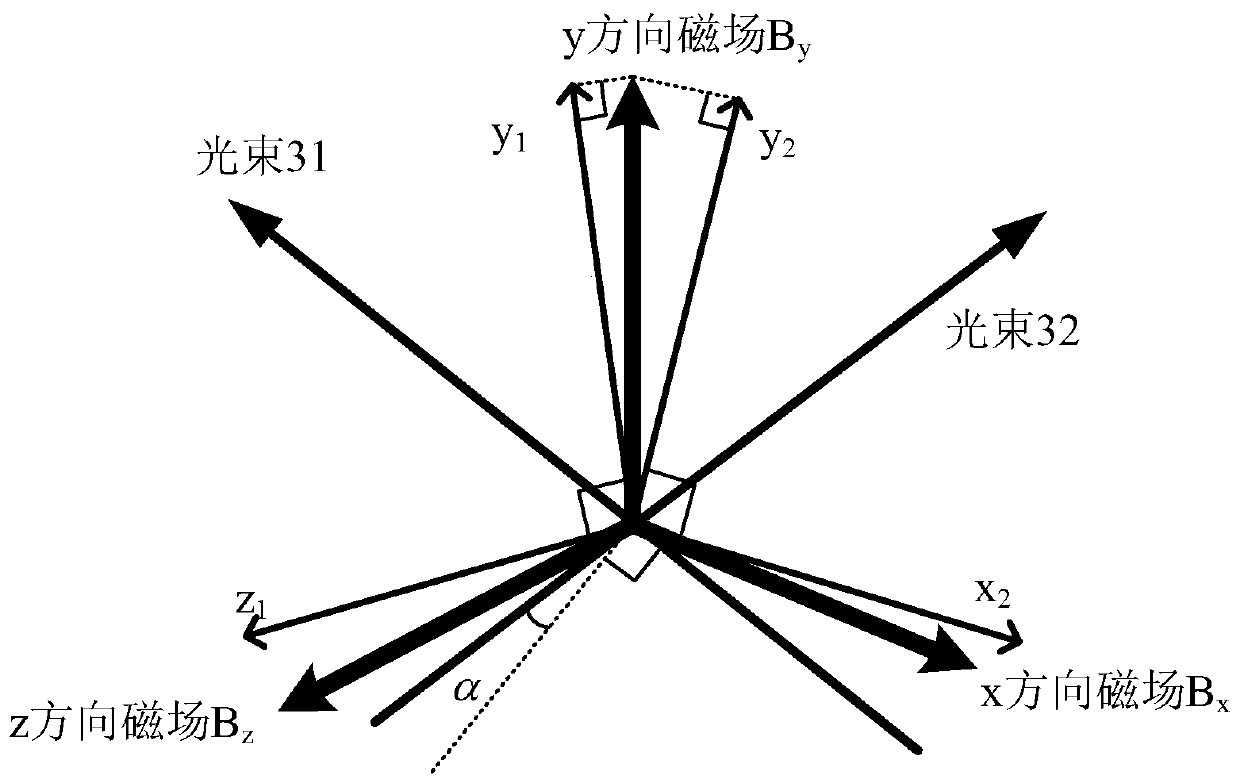

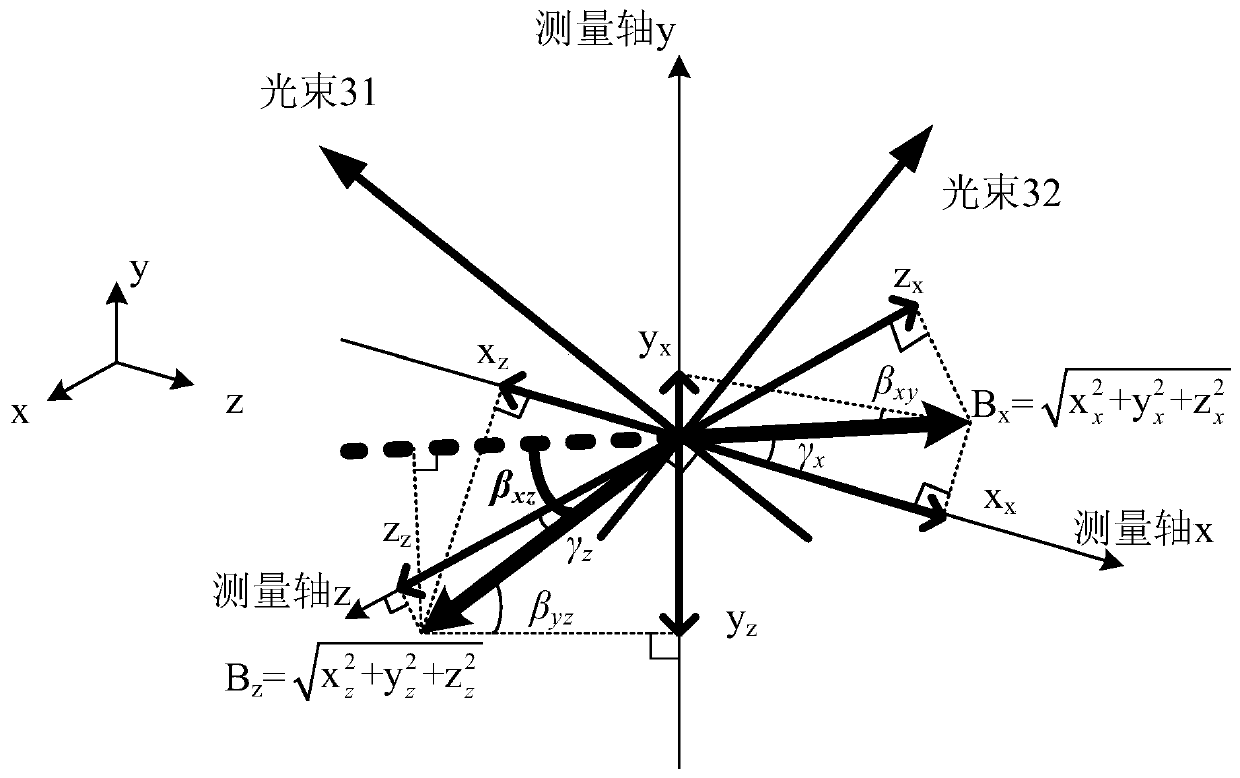

[0031] Below with the accompanying drawings ( figure 1 , Figure 2A , Figure 2B , image 3 ) to illustrate the present invention.

[0032] Such as figure 1 , an in-situ measuring device for optomagnetic non-orthogonal angle based on a three-axis vector atomic magnetometer with double beams includes a laser 1, a beam 2, a 1 / 2 wave plate 3, a polarization beam splitter prism 4, a convex lens 5, a convex lens 6, Mirror 7, polarization beam splitter prism 8, 1 / 4 wave plate 9, convex lens 10, photodetector 11, 1 / 2 wave plate 12, fiber coupler 13, single-mode polarization-maintaining fiber 14, collimator 15, light beam 16 , 1 / 2 wave plate 17, polarization beam splitter prism 18, convex lens 19, convex lens 20, polarization beam splitter prism 21, 1 / 4 wave plate 22, convex lens 23, photodetector 24, lock-in amplifier 25, computer 26, magnetic shield barrel 27. Three-axis magnetic compensation coil 28, non-magnetic electric heating oven 29, alkali metal gas chamber 30, and signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com