Nut processing method capable of effectively preventing mould

A processing method and technology of nuts, applied in the direction of preservation of edible seeds, preservation of seeds through radiation/electrical treatment, preservation of food ingredients as anti-microbial, etc., can solve the problems of over-drying of roasted seeds and nuts, human hazards, and oil spoilage, etc. Achieve excellent bactericidal effect, fast removal speed, and prevent mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

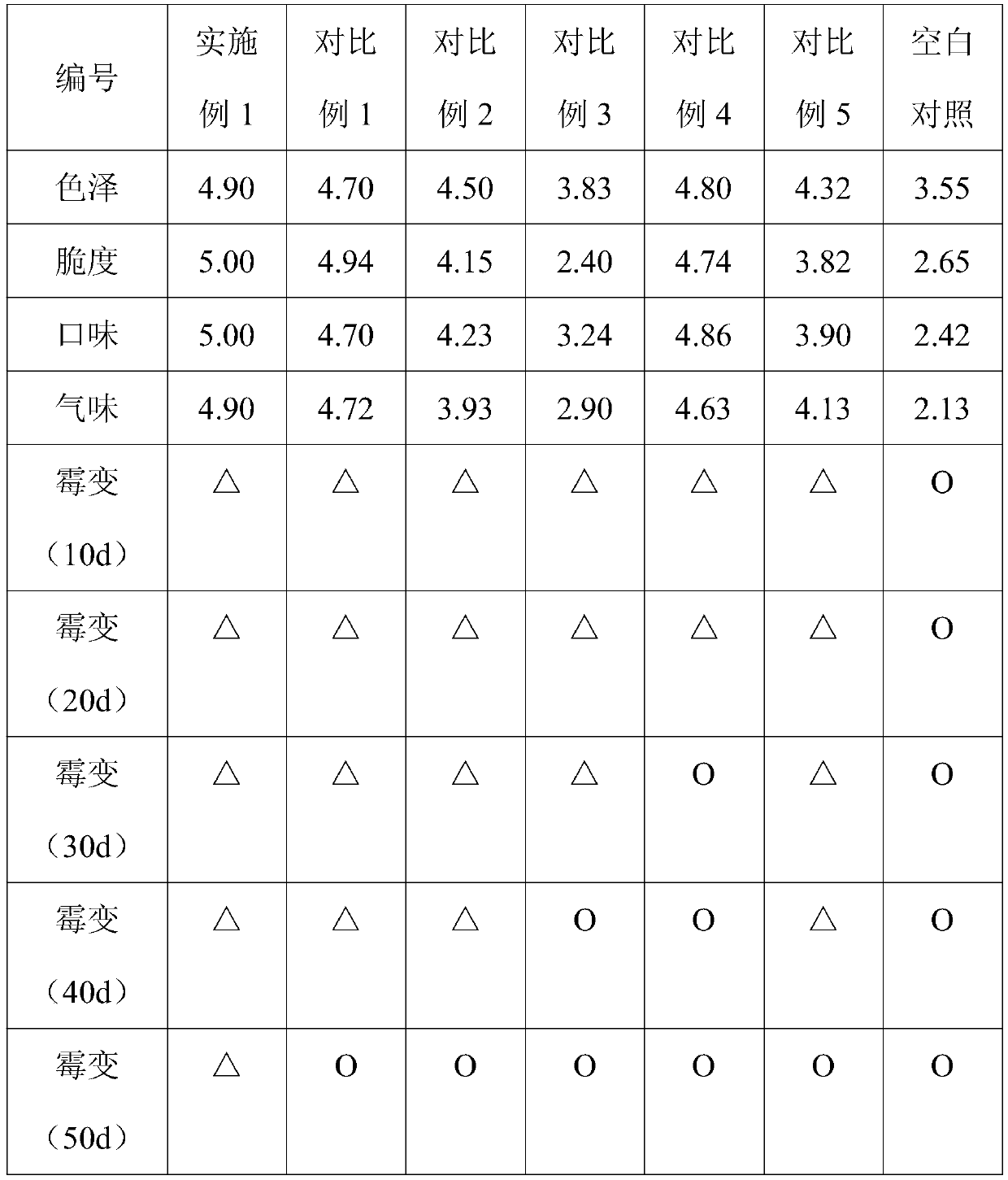

Examples

Embodiment 1

[0031] This embodiment selects peanuts as the processing object, and provides a peanut processing method that effectively prevents mildew, including the following steps:

[0032] (1) Screening: classify and screen the peanut particles to be processed, put them into a bubble cleaner, and wash with water for 40 minutes;

[0033] (2) Dehydration: Rapidly freeze the washed flower granules at -35°C for 2 hours; then heat them with microwaves to 15°C at a pressure of 50Kpa and a heating rate of 8°C / min, and bake for 40 minutes; then , the heated nut particles were rapidly frozen at -25°C for 1 hour; then heated to 40°C by microwave at a pressure of 20Kpa and a heating rate of 6°C / min, and baked Bake for 40 minutes;

[0034] (3) Ultraviolet sterilization: the peanut granules prepared in step (2) are placed under an ultraviolet lamp for sterilization, the time is 8min, and the power of the ultraviolet lamp is 150W;

[0035] (4) Pressurized frying: put the peanut granules prepared in...

Embodiment 2

[0039] The present embodiment selects walnut as processing object, provides a kind of walnut processing method effectively preventing mildew, comprises the following steps:

[0040](1) Screening: classify and screen the walnut particles to be processed, put them into a bubble cleaner, and wash them with water for 50 minutes;

[0041] (2) Dehydration: Rapidly freeze the cleaned walnut particles at -30°C for 1 hour; then heat to 25°C by microwave at a pressure of 80Kpa and a heating rate of 10°C / min, and bake for 60 minutes; then , rapidly freezing the heated walnut particles at -25°C for 1 hour; then heating to 30°C with microwaves at a pressure of 30Kpa and a heating rate of 10°C / min, and baking for 50 minutes;

[0042] (3) Ultraviolet sterilization: the walnut granules prepared in step (2) are placed under an ultraviolet lamp for sterilization, the time is 10min, and the power of the ultraviolet lamp is 200W;

[0043] (4) Pressure frying: put the walnut granules prepared in ...

Embodiment 3

[0048] The present embodiment selects pine nut as processing object, provides a kind of pine nut processing method effectively preventing mildew, comprises the following steps:

[0049] (1) Screening: classify and screen the pine nut particles to be processed, put them into a bubble cleaner, and wash them with water for 50 minutes;

[0050] (2) Dehydration: Rapidly freeze the cleaned pine nut particles at -25°C for 1 hour; then heat to 20°C by microwave at a pressure of 60Kpa and a heating rate of 9°C / min, and bake for 50 minutes; , the heated pine nut particles were rapidly frozen at -25°C for 1 hour; then heated to 45°C by microwave at a pressure of 20Kpa and a heating rate of 10°C / min, and baked for 60 minutes;

[0051] (3) ultraviolet sterilization: the pine nut particle that step (2) makes is placed under ultraviolet lamp and sterilizes, and the time is 10min, and the power of ultraviolet lamp is 200W;

[0052] (4) Stir-frying under pressure: place the pine nut particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com