Amplitude modulation type radial polarization illumination confocal microimaging method and device

A confocal microscopic imaging and amplitude modulation technology, used in microscopes, optics, instruments, etc., can solve the problems of high processing accuracy and complex design process of binary optical components, achieve noise suppression, optimize confocal pinhole size, The effect of improving imaging resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation examples of the present invention will be described in detail below in conjunction with the accompanying drawings.

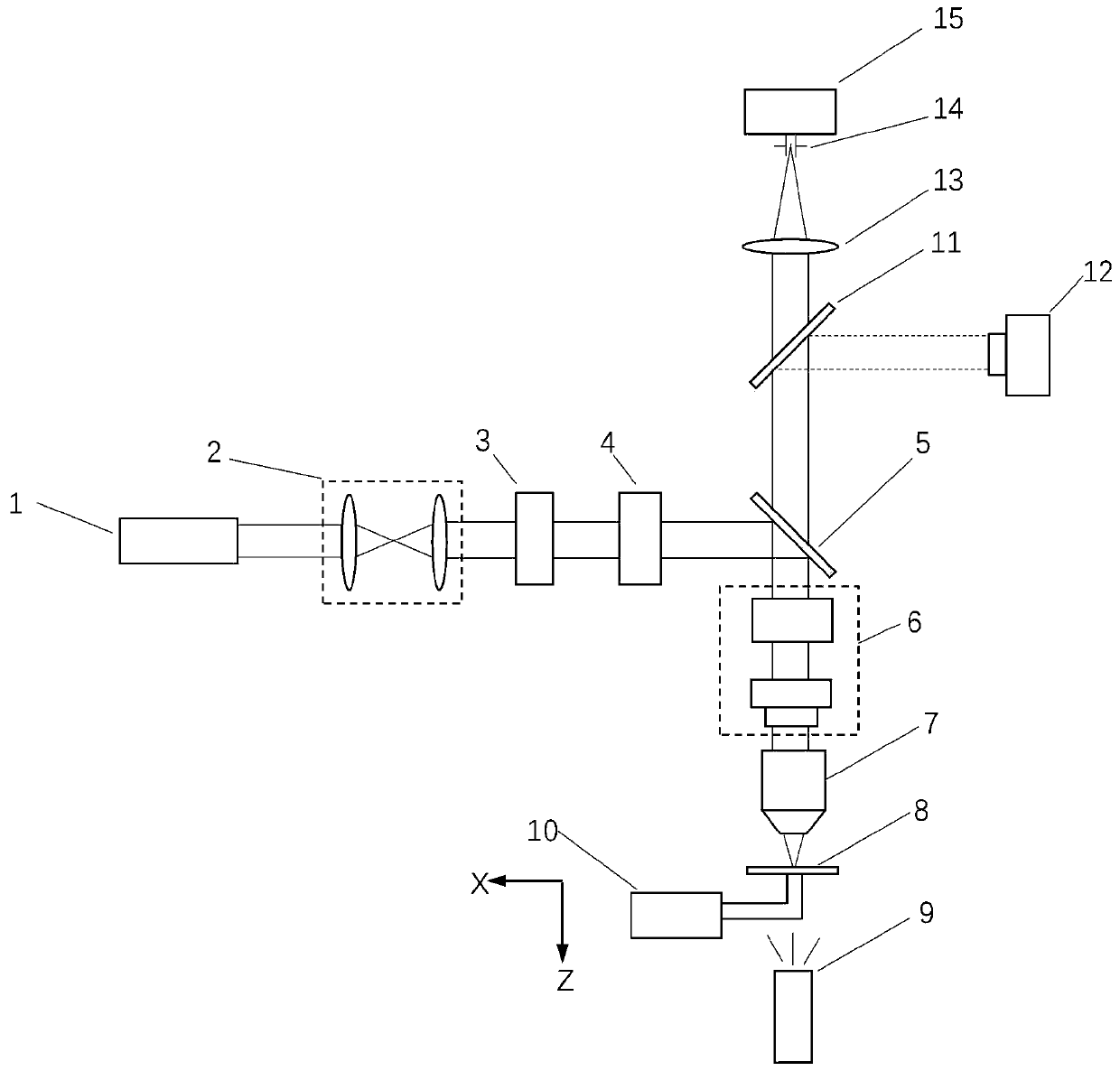

[0025] The schematic diagram of the amplitude-modulated radially polarized illumination confocal microscopy imaging method and device in this embodiment is as follows figure 1 shown. The linearly polarized laser light emitted by the laser 1 is shaped and expanded by the collimator beam expander system 2 and then enters the polarization state conversion system 3 to become radially polarized light. Then the beam enters the transmissive amplitude spatial light modulator 4 . The spatial light modulator is controlled by a computer to perform amplitude modulation on the light intensity of the entrance pupil plane. The modulated radially polarized light is reflected by the first beam splitter 5 , passes through the scanning galvanometer system 6 and is focused by the high numerical aperture objective lens 7 to perform point detection on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com