Solid-state battery and preparation method thereof

A solid-state battery and solid-state electrolyte technology, applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve problems such as large interface resistance, achieve the effects of improving compatibility, perfecting conductive network, and reducing battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

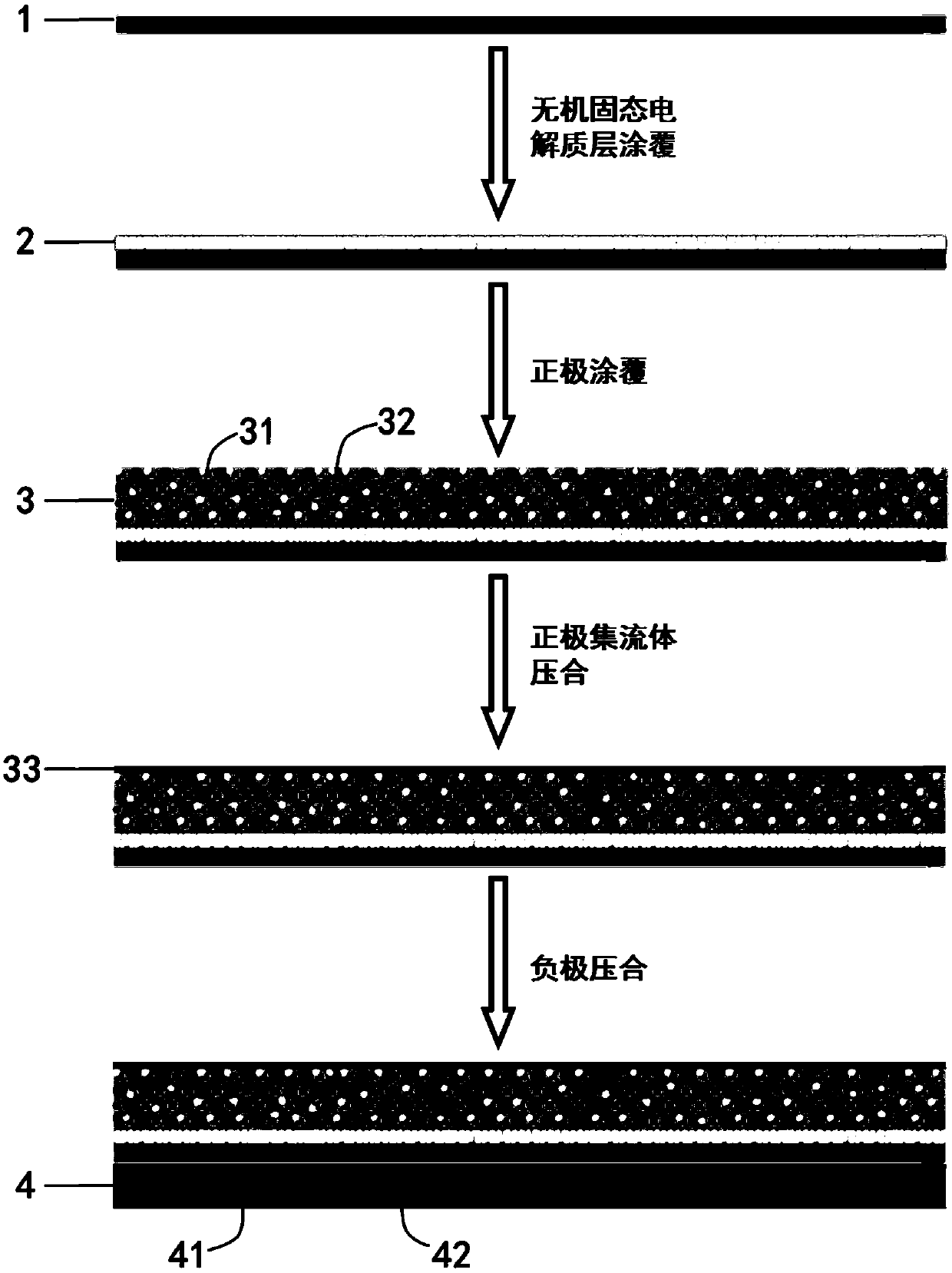

[0039] The solid-state battery of this embodiment, the schematic diagram of the specific preparation process is as follows figure 1 As shown, the following steps are taken:

[0040] 1) Dissolving the polymer electrolyte (polymer matrix and lithium salt) in acetonitrile to prepare a polymer electrolyte slurry, coating the polymer electrolyte slurry on the substrate, and peeling off from the substrate after drying to obtain a polymer electrolyte layer .

[0041] 2) Add the inorganic solid electrolyte and the polymer electrolyte to the solvent acetonitrile to disperse evenly to obtain the inorganic electrolyte layer slurry, coat the inorganic electrolyte layer slurry on one side surface of the polymer electrolyte layer, and dry it on the surface of the polymer electrolyte layer An inorganic electrolyte layer is formed.

[0042] 3) Add positive electrode materials, conductive additives, polymer electrolytes, and inorganic solid electrolytes into dimethylformamide DMF to disperse...

Embodiment 2

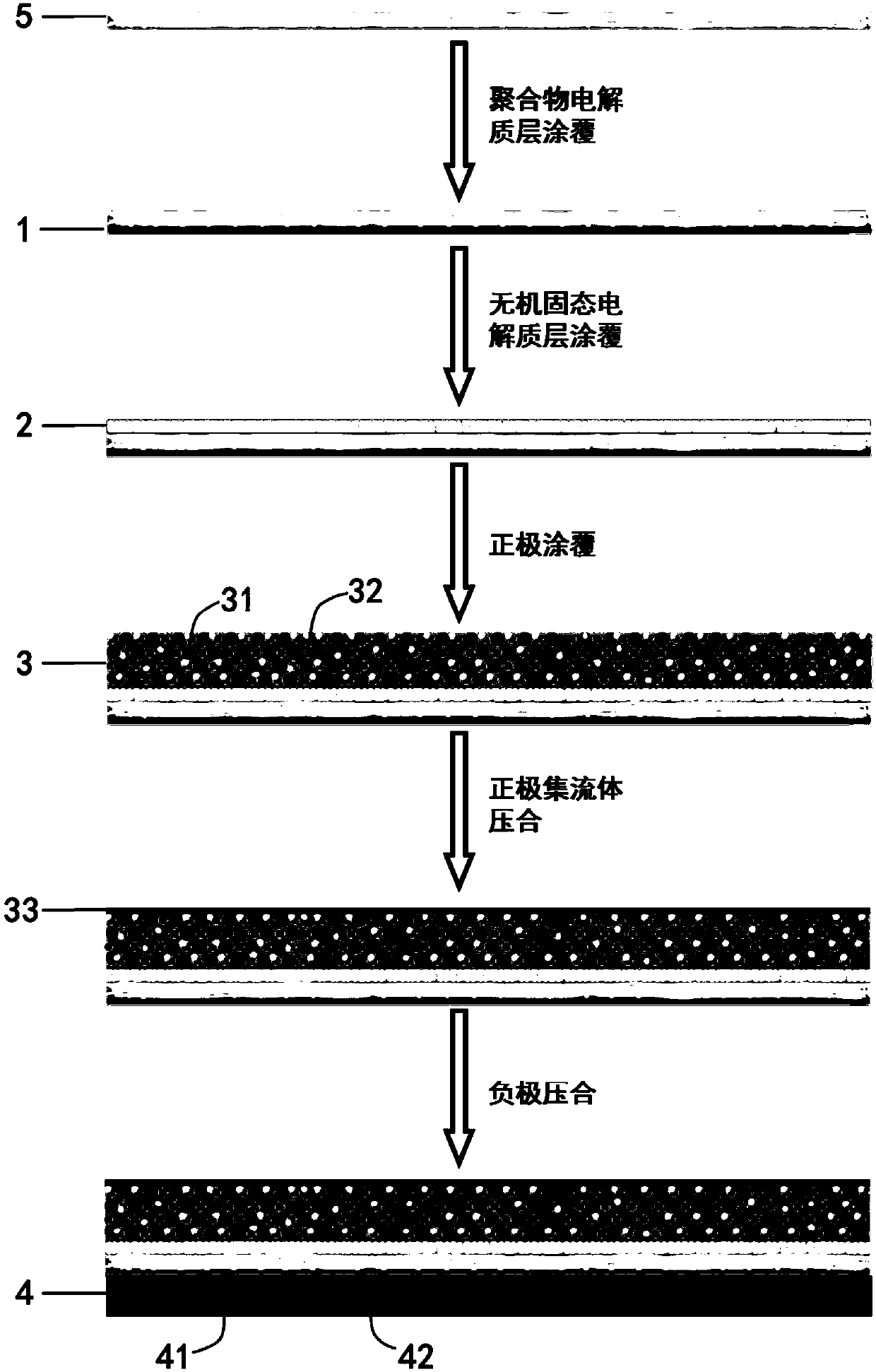

[0049] The solid-state battery of this embodiment, the schematic diagram of the specific preparation process is as follows figure 2 As shown, the following steps are taken:

[0050] 1) Add polymer electrolyte and inorganic solid electrolyte to acetonitrile to disperse evenly, then pour into the porous support framework (or immerse the porous support framework in the pouring slurry for 5 minutes), and form the support framework layer after drying.

[0051] 2) dissolving the polymer electrolyte in acetonitrile to prepare a polymer electrolyte slurry, coating the polymer electrolyte slurry on the surface of the negative electrode side of the supporting skeleton layer, and forming a polymer electrolyte layer after drying;

[0052] Adding inorganic solid electrolyte and polymer electrolyte into acetonitrile and dispersing evenly to obtain inorganic electrolyte layer slurry, coating the inorganic electrolyte layer slurry on the surface of the positive electrode side of the supporti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com