Composite solid electrolyte membrane with multilayer structure, preparation method thereof and solid-state battery

A technology of solid electrolyte membrane and solid electrolyte, applied in solid electrolyte, non-aqueous electrolyte, battery, etc., can solve the problems of poor mechanical strength, etc., and achieve the effect of improving rate performance, good performance, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

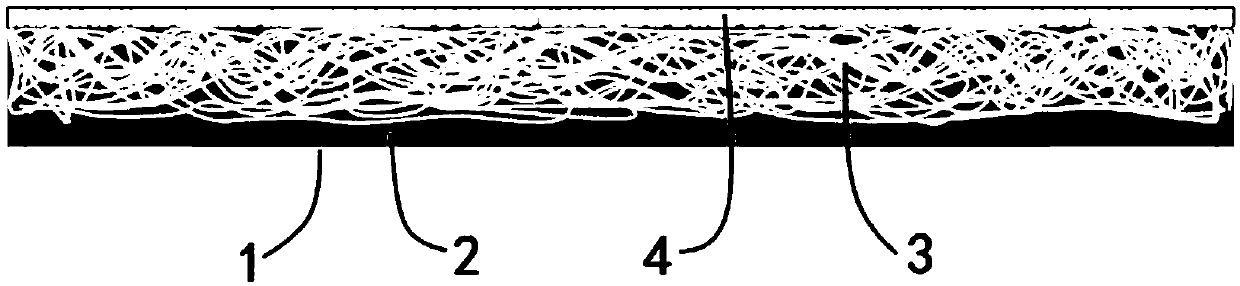

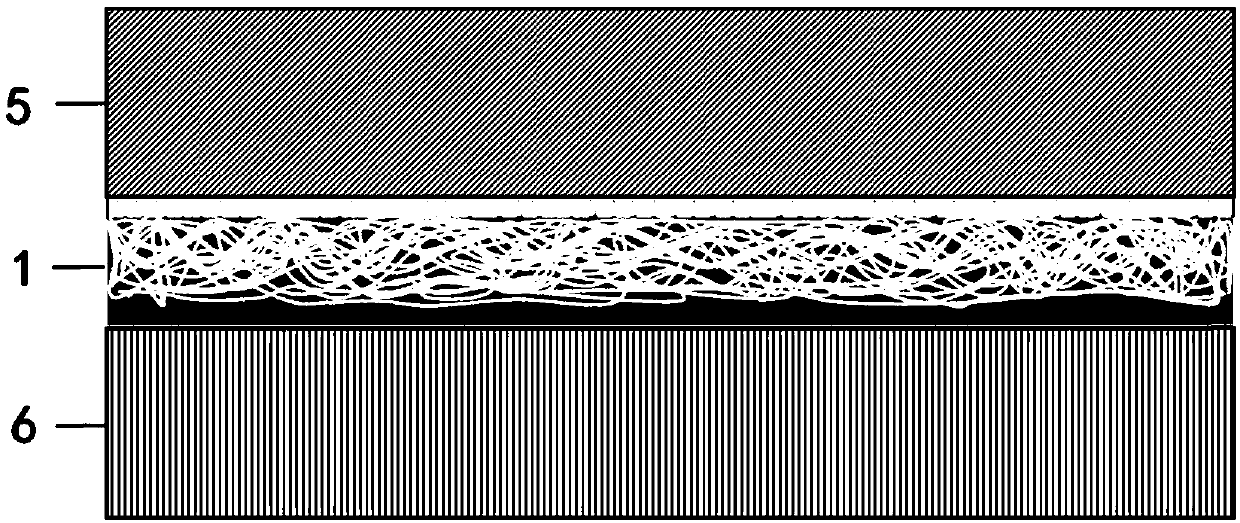

[0042] The multi-layer structure composite solid electrolyte membrane of this embodiment, the structure schematic diagram is as follows figure 1 As shown, it includes a supporting framework layer 3, the positive electrode side surface of the supporting framework layer is compounded with an inorganic electrolyte layer 4, the negative electrode side surface is compounded with a polymer electrolyte layer 2, the supporting framework layer includes a porous supporting framework, and the pore structure of the porous supporting framework is filled There is an electrolyte material connecting the inorganic electrolyte layer and the polymer electrolyte layer, and the inorganic electrolyte layer 4, the supporting skeleton layer 3, and the polymer electrolyte layer 2 form a composite solid electrolyte membrane 1 with a multilayer structure.

[0043] The inorganic electrolyte layer is composed of an inorganic solid electrolyte and a polymer electrolyte, and the polymer electrolyte simultane...

Embodiment 2

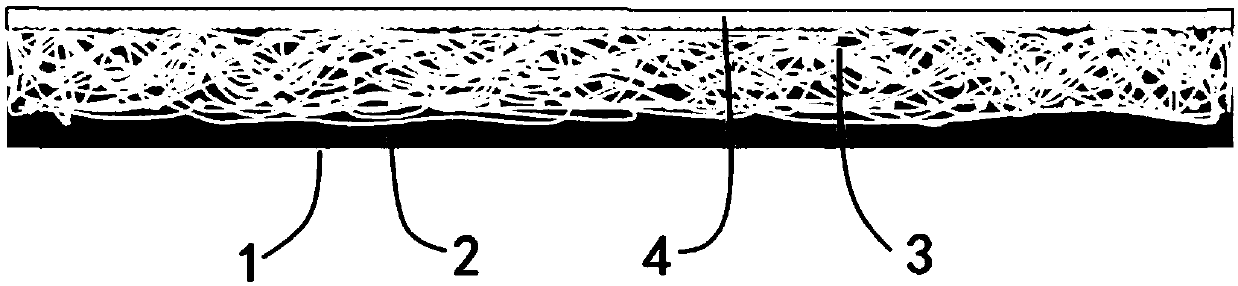

[0053] The multi-layer structure composite solid electrolyte membrane of this embodiment, the structure schematic diagram is as follows figure 2 As shown, it includes a supporting framework layer 3, the positive electrode side surface of the supporting framework layer is compounded with an inorganic electrolyte layer 4, the negative electrode side surface is compounded with a polymer electrolyte layer 2, the supporting framework layer includes a porous supporting framework, and the pore structure of the porous supporting framework is filled There is an electrolyte material connecting the inorganic electrolyte layer and the polymer electrolyte layer, and the inorganic electrolyte layer 4, the supporting skeleton layer 3, and the polymer electrolyte layer 2 form a composite solid electrolyte membrane 1 with a multilayer structure.

[0054] The inorganic electrolyte layer is composed of an inorganic solid electrolyte and a polymer electrolyte, and the polymer electrolyte simultan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com