Seasoning soy sauce and preparation method thereof

A technology for seasoning soy sauce and soy sauce, applied in separation methods, chemical instruments and methods, and food ingredients as taste improvers, etc., can solve the problems of single efficacy of traditional soy sauce, and achieve single efficacy, better effect, and faster mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

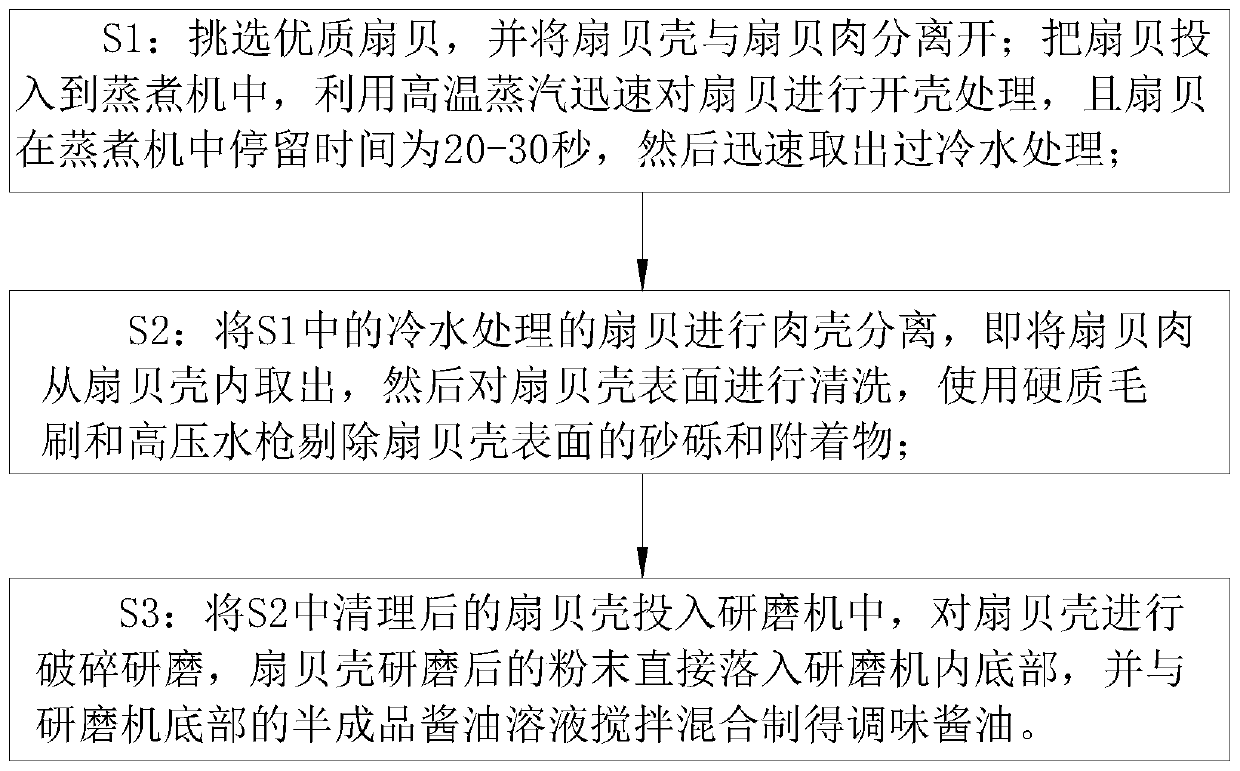

Method used

Image

Examples

Embodiment 1

[0031] A seasoning soy sauce and a preparation method thereof, which are prepared from the following raw materials in parts by weight: 13 parts of soy sauce powder, 4 parts of malt, 3 parts of sealwort, 3 parts of longan meat, 22 parts of scallops, 12 parts of table salt, sorbic acid 1 part of sodium, 2 parts of garlic juice, 8 parts of vegetable juice, 35 parts of purified water;

[0032] The seasoning soy sauce is prepared by weighing raw materials according to the weight ratio of the above raw materials.

Embodiment 2

[0034] A seasoning soy sauce and a preparation method thereof, which are prepared from the following raw materials in parts by weight: 13 parts of soy sauce powder, 4 parts of malt, 3 parts of sealwort, 3 parts of longan meat, 25 parts of scallops, 12 parts of table salt, sorbic acid 1 part of sodium, 2 parts of garlic juice, 8 parts of vegetable juice, 35 parts of purified water;

[0035] The seasoning soy sauce is prepared by weighing raw materials according to the weight ratio of the above raw materials.

Embodiment 3

[0037] A seasoning soy sauce and a preparation method thereof, which are prepared from the following raw materials in parts by weight: 13 parts of soy sauce powder, 4 parts of malt, 3 parts of sealwort, 3 parts of longan meat, 26 parts of scallops, 12 parts of table salt, and sorbic acid 1 part of sodium, 2 parts of garlic juice, 8 parts of vegetable juice, 35 parts of purified water;

[0038] The seasoning soy sauce is prepared by weighing raw materials according to the weight ratio of the above raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com