Waste fiber-fabric-inorganic particle four-layer casting composite stab-resistant sheet, preparation method and applications thereof

A technology of inorganic particles and waste fibers, applied in chemical instruments and methods, protective equipment, other household appliances, etc., can solve the problems of insufficient material stiffness, uneven overlap of anti-stab effects, uniform structure, etc., and achieves high industrial feasibility. , The preparation cycle is adjustable, and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

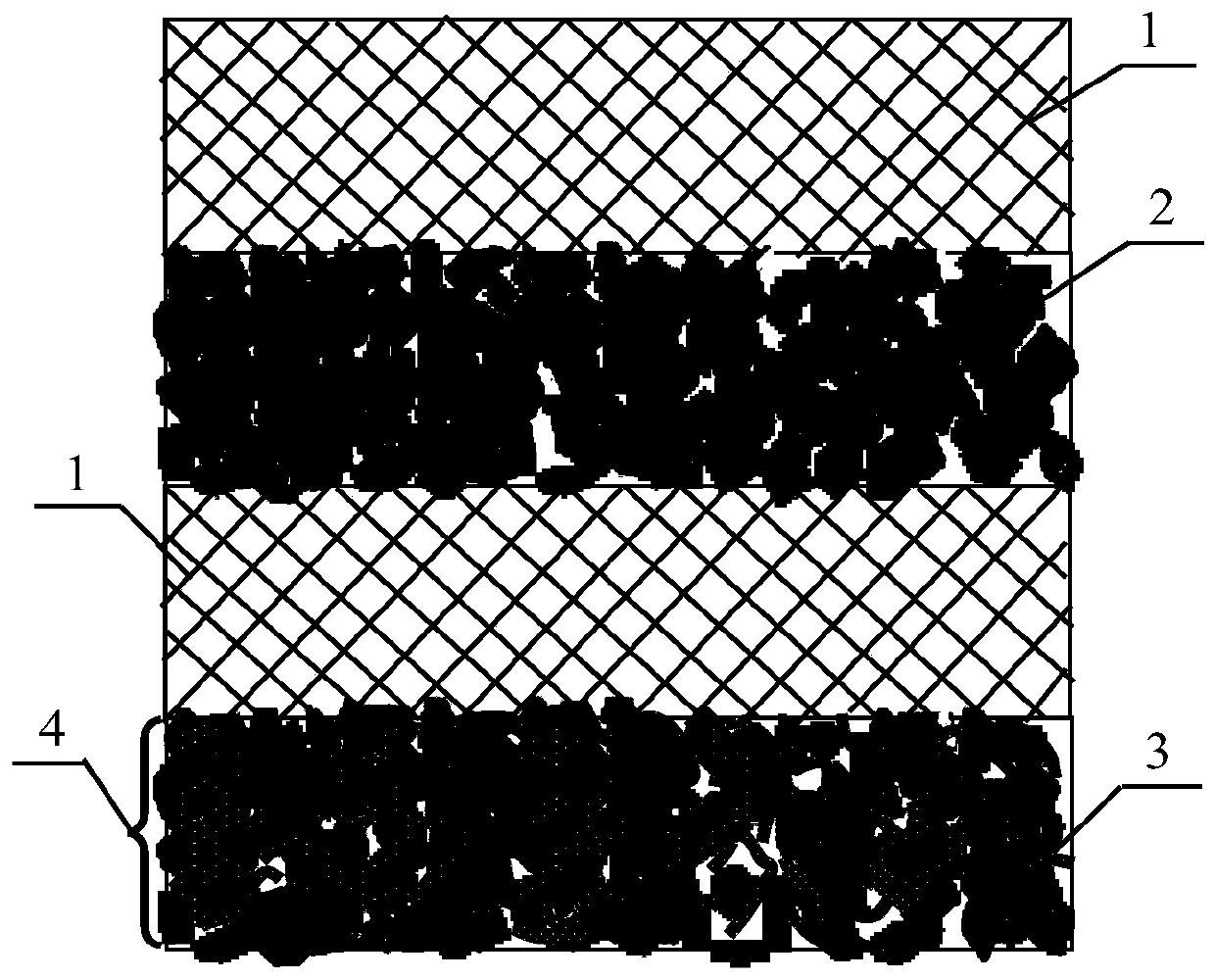

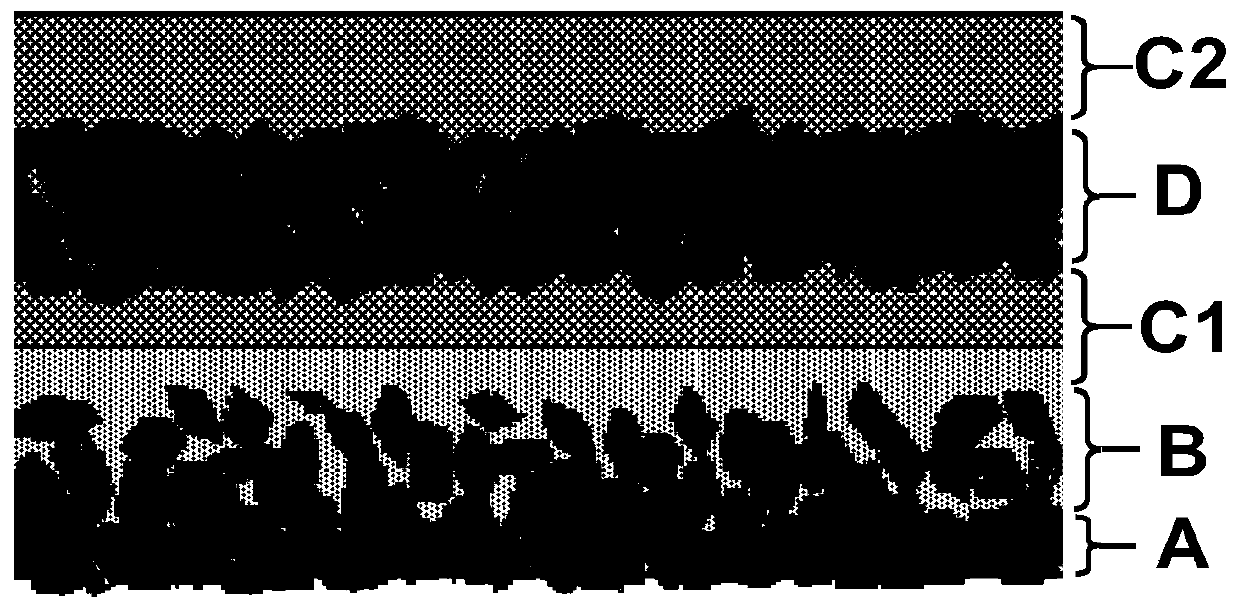

[0031] Such as Figure 1-2 As shown, the present invention provides the preparation method of waste fiber and fabric and inorganic particle four-layer melting and casting composite stab-proof sheet, and concrete steps are as follows:

[0032] (1) Evenly mix waste fiber cut sections with inorganic particles with a set filling mass fraction, and then spread the mixture evenly and multi-layered in the formwork tank box to achieve the thickness of the first layer and the uniform mixing of the two mixtures , and then slightly vibrate the template tank box horizontally for 2 to 4 times to achieve a uniform thickness of the layer mixture;

[0033] (2) Place a layer of waste fabric sheet on the mixture layer prepared in (1), and then evenly spread inorganic particles on it to the set filling mass fraction, and then place a layer of waste fabric on it. Fabric sheets to obtain complete four-ply prefabricated samples;

[0034] (3) When using waste fiber cut sections and fabric pieces w...

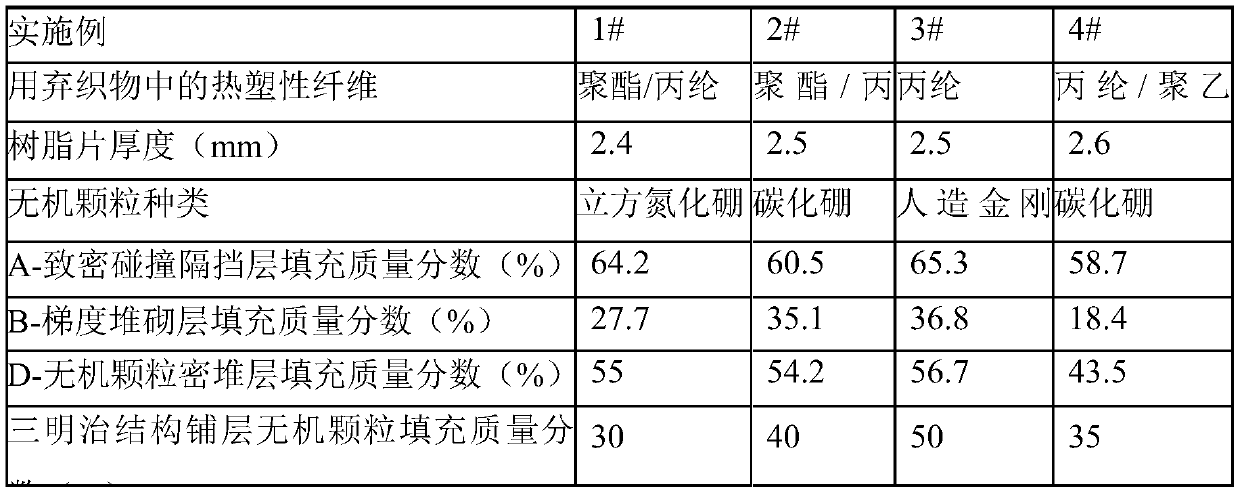

Embodiment 1

[0039] Boron nitride particles with an average particle size of 100 μm and discarded polyester and polypropylene fabrics are mixed and laid at intervals, and the overall square meter weight of the multi-layer composite fabric formed by attaching a composite anti-stab sheet on the multi-layer fabric is 5.29kg / m 2 , see Table 1 for details. The puncture probability of this composite fabric is zero. If converted into the current 6.66kg / m 2 The fabric has a puncture-resistant energy of 28.9J, which is equivalent to the current conventional square meter weight (6.66kg / m 2 ), it can reduce the weight by about 20.6%, which shows that its anti-stab performance has been improved, and it can be lightened and softened.

Embodiment 2

[0041] Boron carbide particles with an average particle size of 200 μm and discarded polyester and polypropylene fabrics are mixed and laid at intervals, and the overall square meter weight of the multi-layer composite fabric formed by attaching a composite anti-stab sheet to the multi-layer fabric is 5.35 kg / m 2 , see Table 1 for details. The puncture probability of this composite fabric is zero. If converted into the current 6.66kg / m 2 The fabric has a puncture resistance energy of 29.1J, which is equivalent to the current conventional square meter weight (6.66kg / m 2 ), the weight can be reduced by about 19.7%, which shows that its anti-stab performance has been improved, and it can be lightened and softened.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com