Temperature-resistant sterilized aluminum foil with cover easy to tear

A technology of easy-tear cover and aluminum foil, which is applied in the field of packaging, can solve the problems of non-bacteria barrier and sterilization performance, poor temperature resistance of easy-tear cover aluminum foil, and can not be heated by microwave ovens, etc., and achieve good antibacterial and sterilization effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

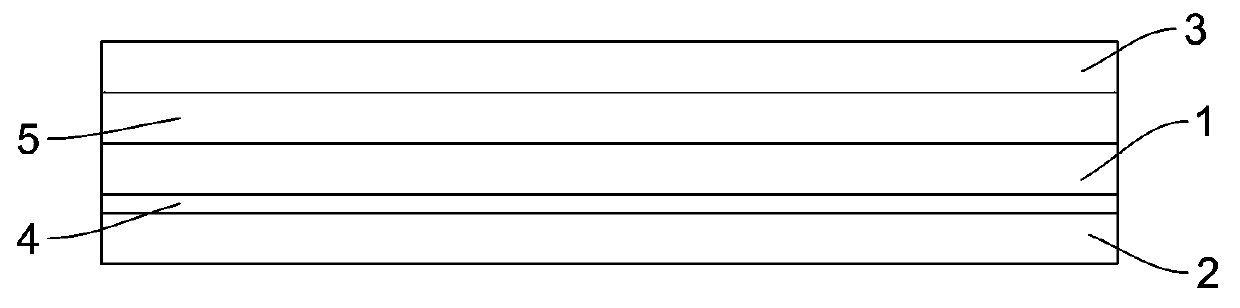

[0023] A kind of temperature-resistant sterilization easy-to-tear aluminum foil, such as figure 1 As shown, it includes an aluminum foil barrier layer 1, and also includes a CPP film layer 2 arranged on one side of the aluminum foil barrier layer 1 for bonding to tinplate, and a paint protection layer 3 arranged on the other side of the aluminum foil barrier layer 1; the aluminum foil barrier layer 1 A pattern printing layer 5 is also arranged between the coating protection layer 3 .

[0024] In this embodiment, the preparation method of this temperature-resistant sterilization easy-tear aluminum foil includes the following steps:

[0025] (1) Prepare the aluminum base.

[0026] (2) Under 15V DC voltage, place the aluminum base layer in 15wt% sulfuric acid electrolyte for electrochemical oxidation, the graphite electrode is the counter electrode, the solution temperature is 18°C, the anodizing time is 40min, and the aluminum anode is prepared on the aluminum base layer Oxide...

Embodiment 2

[0031] In this embodiment, the preparation method of this temperature-resistant sterilization easy-tear aluminum foil includes the following steps:

[0032] (1) Prepare the aluminum base.

[0033] (2) Under the DC voltage of 15V, place the aluminum base layer in 15wt% sulfuric acid electrolyte for electrochemical oxidation, the graphite electrode is the counter electrode, the solution temperature is 22°C, and the anodic oxidation time is 60min, and the aluminum anode is prepared on the aluminum base layer Oxide film layer.

[0034] (3) Preparation of modified nano-silica: Superdisperse 3 g of nano-silica in deionized water, and add 100 mL of 5.5×10 -5 mol / L copper sulfate solution, stirred for 3 hours after the dropwise addition, the dispersed suspension was allowed to stand for 40 minutes, then centrifuged, filtered, washed, dried and pulverized to obtain sterilized modified nano silicon dioxide.

[0035] (4) According to parts by mass, mix 60 parts of polypropylene resin, ...

Embodiment 3

[0039] In this embodiment, the preparation method of this temperature-resistant sterilization easy-tear aluminum foil includes the following steps:

[0040] (1) Prepare the aluminum base.

[0041] (2) Under a DC voltage of 15V, place the aluminum base layer in a 15wt% sulfuric acid electrolyte for electrochemical oxidation, the graphite electrode is the counter electrode, the solution temperature is 20°C, and the anodic oxidation time is 50 minutes, and the aluminum anode is prepared on the aluminum base layer Oxide film layer.

[0042] (3) Preparation of modified nano-silica: Ultra-disperse 2.5g of nano-silica in deionized water, and drop 100mL of 5×10 -5 mol / L copper sulfate solution, stirred for 2.5 hours after the dropwise addition, and the dispersed suspension was left to stand for 35 minutes, then centrifuged, filtered, washed, dried, and pulverized to obtain sterilized modified nano-silica.

[0043] (4) According to parts by mass, mix 55 parts of polypropylene resin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com