Mildew-proof sterilization composition and preparation method and application thereof

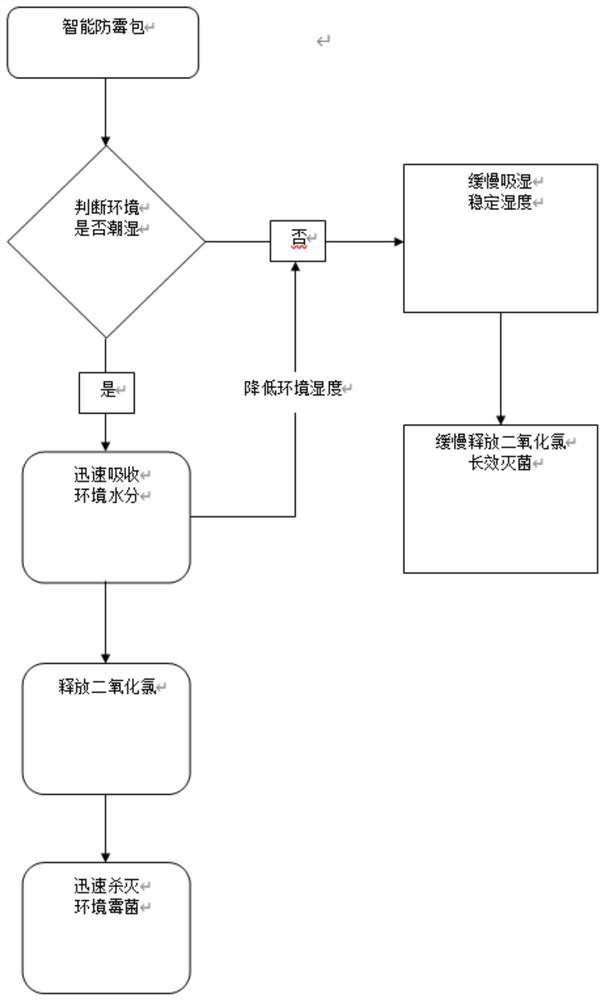

A composition and anti-mildew technology, applied in the direction of botany equipment and methods, applications, separation methods, etc., can solve the problems of short antibacterial time, unfavorable protection products for long-term storage, only rapid killing, high cost, etc., and achieve easy realization The effects of large-scale production, prolonged sterilization duration, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

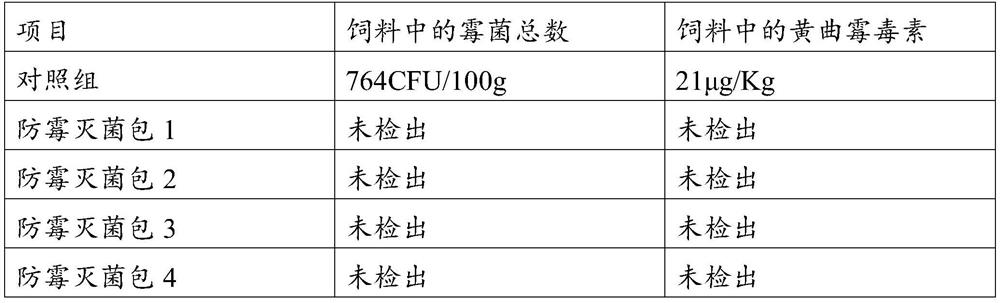

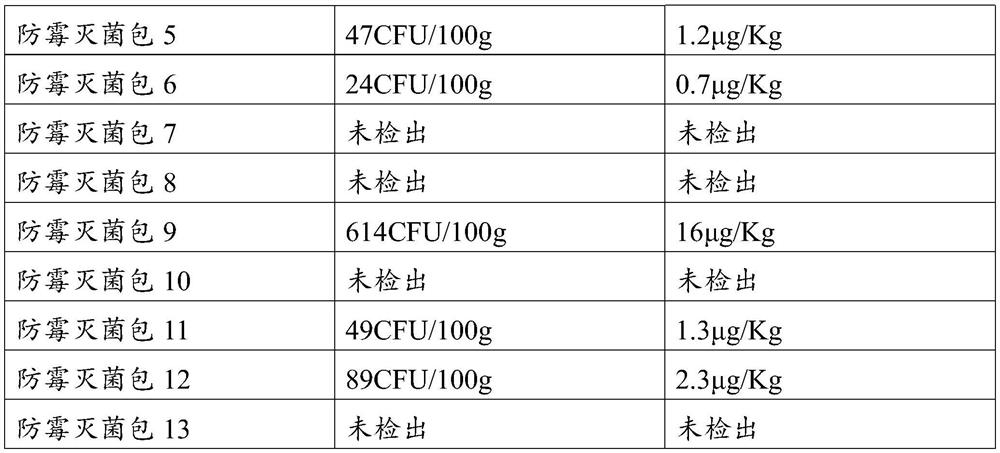

Examples

Embodiment 1

[0034] A kind of anti-mold and sterilization composition of the embodiment of the present invention, comprises the component of following mass percent: 19% anhydrous calcium chloride, 5% citric acid monohydrate, 43% cornstarch, 13% calcium chlorite and 20% % Precipitated silica, wherein the mass ratio of anhydrous calcium chloride to calcium chlorite is 1.46:1.

[0035] The preparation method of the mildew-proof and sterilizing composition described in the present embodiment is as follows:

[0036] Each component was weighed by mass percentage and placed in a spiral mixer for uniform mixing to obtain the anti-mildew and sterilization composition 1.

Embodiment 2

[0038]A kind of anti-mold and sterilization composition of the embodiment of the present invention, comprises the component of following mass percent: 15% calcium chloride anhydrous, 3% citric acid monohydrate, 37% cornstarch, 10% calcium chlorite and 35% % Precipitated silica, wherein the mass ratio of anhydrous calcium chloride to calcium chlorite is 1.5:1.

[0039] The preparation method of the mildew-proof and sterilizing composition described in the present embodiment is as follows:

[0040] Each component was weighed by mass percentage and placed in a spiral mixer for uniform mixing to obtain the anti-mold and sterilization composition 2.

Embodiment 3

[0042] A kind of anti-mold and sterilization composition of the embodiment of the present invention, comprises the component of following mass percent: 10% calcium chloride anhydrous, 2% citric acid monohydrate, 30% cornstarch, 15% calcium chlorite and 43 % kaolin, wherein the mass ratio of anhydrous calcium chloride to calcium chlorite is 0.67:1.

[0043] The preparation method of the mildew-proof and sterilizing composition described in the present embodiment is as follows:

[0044] Each component was weighed by mass percentage and placed in a spiral mixer for uniform mixing to obtain the anti-mold and sterilization composition 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com