A kind of preparation method of nano-zinc oxide-wrapped nano-silver antibacterial composite material

A nano-zinc oxide and nano-silver antibacterial technology, applied in chemical instruments and methods, botanical equipment and methods, separation methods, etc., can solve the problems of weakening the synergistic antibacterial effect of silver, reduce the composite probability, improve the photocatalytic efficiency, The effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

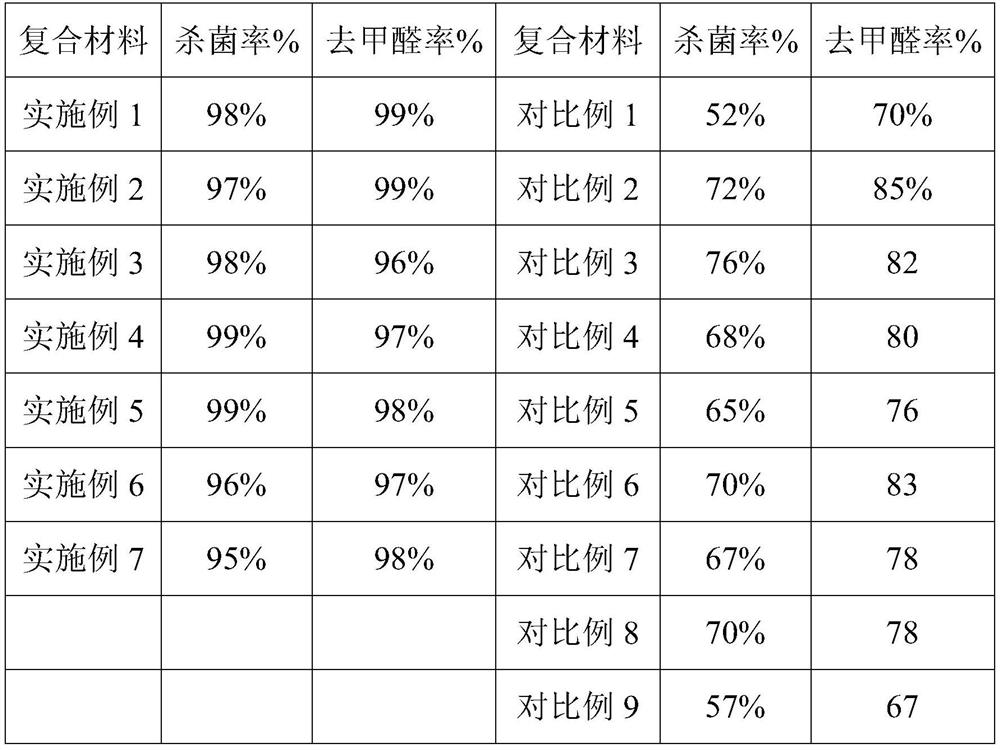

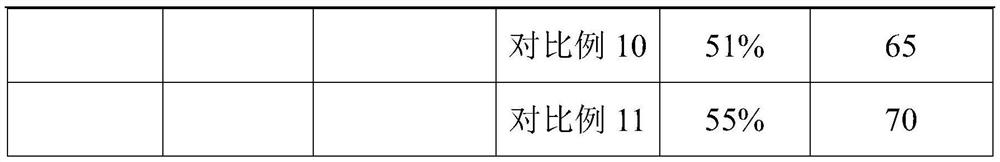

Examples

Embodiment 1

[0032] The present embodiment provides a method for preparing a nano-zinc oxide-wrapped nano-silver antibacterial composite material, which specifically includes the following steps:

[0033] (1) dissolve zinc nitrate in water to form a uniform solution, then add the dispersion of cetyl trimethyl ammonium bromide (water is a solvent) to it, the addition of cetyl trimethyl ammonium bromide It is 3% of the mass of zinc nitrate. In the case of stirring, quickly pour an equimolar sodium hydroxide solution with zinc nitrate, stir at room temperature (25-30 ° C) for 3 hours, then let the reaction solution stand, and filter and collect it within 24 hours. Precipitation, the precipitation was washed with water for many times and then heat-treated at 400 °C for 4 h to obtain porous nano-zinc oxide. The particle size and pore size of the obtained porous nano-zinc oxide were observed with a particle size analyzer.

[0034] (2) Disperse 1g of silane coupling agent γ-aminopropyltriethoxys...

Embodiment 2

[0040] The present embodiment provides a method for preparing a nano-zinc oxide-wrapped nano-silver antibacterial composite material, which specifically includes the following steps:

[0041] (1) dissolve zinc chloride in water to form a homogeneous solution, then add a dispersion of cetyltrimethylammonium bromide and SBA-15 molecular sieve (water is a solvent) to it, cetyltrimethylammonium The amount of ammonium bromide and SBA-15 molecular sieve added is 1.5% of the mass of zinc nitrate, respectively. In the case of stirring, quickly pour the sodium hydroxide solution equal to the mole of zinc nitrate, and stir at room temperature (25-30 ° C) After 5 hours, the reaction solution was allowed to stand, and the precipitate was collected by filtration within 24 hours. The precipitate was washed with water for several times and then heat-treated at 600° C. for 5 hours to obtain porous nano-zinc oxide. The particle size and pore size of the obtained porous nano zinc oxide are obse...

Embodiment 3

[0047] The present embodiment provides a method for preparing a nano-zinc oxide-wrapped nano-silver antibacterial composite material, which specifically includes the following steps:

[0048] (1) Dissolve zinc sulfate in water to form a uniform solution, then add a dispersion of polyvinylpyrrolidone and sodium dodecylbenzenesulfonate (water is a solvent), polyvinylpyrrolidone and dodecylbenzenesulfonic acid to it The amount of sodium added is 1.5% of the mass of zinc nitrate. In the case of stirring, quickly pour an equimolar sodium hydroxide solution with zinc nitrate, stir at room temperature (25-30 ° C) for 5 hours, and then let the reaction solution stand still , the precipitate was collected by filtration within 24h, and the precipitate was washed with water for several times and then heat-treated at 650°C for 5h to obtain porous nano-zinc oxide. The particle size and pore size of the obtained porous nano zinc oxide are observed with a particle size analyzer, and the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com