Isophthalonitrile continuous rectification and purification device

An isophthalonitrile and rectification technology, which is applied in the purification/separation of carboxylic acid nitrile, organic chemistry, etc., can solve the problems of unstable quality and low purity of isophthalonitrile products, and achieve continuous stability improvement, The effect of high yield and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

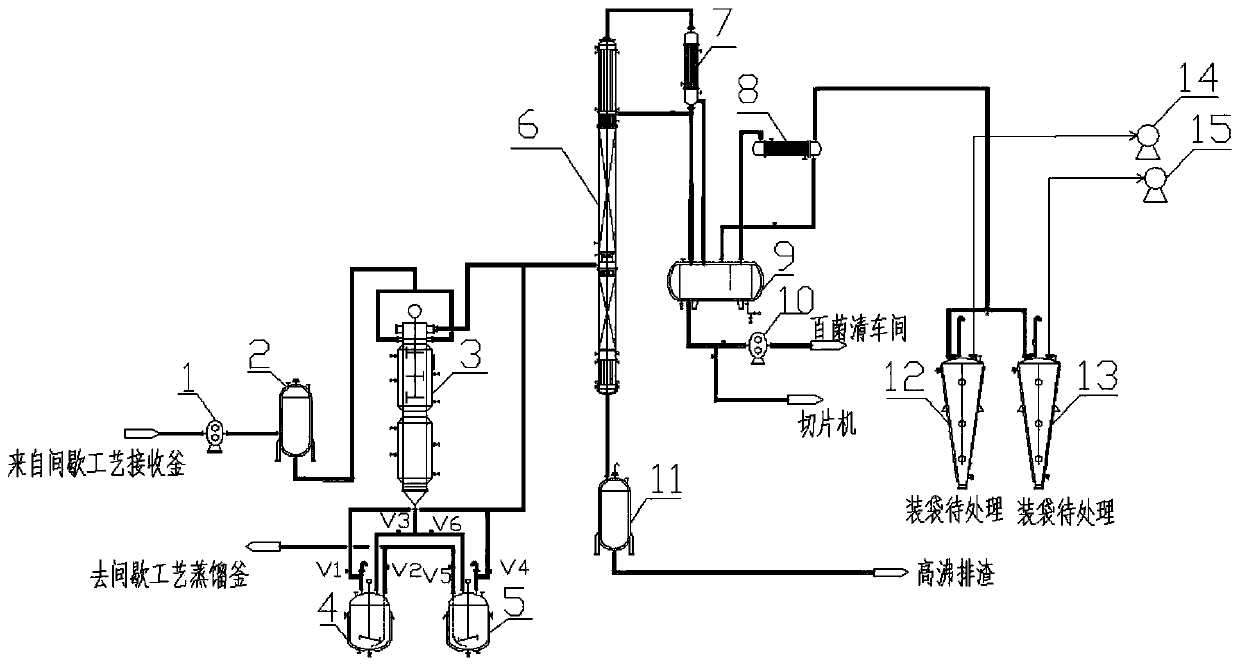

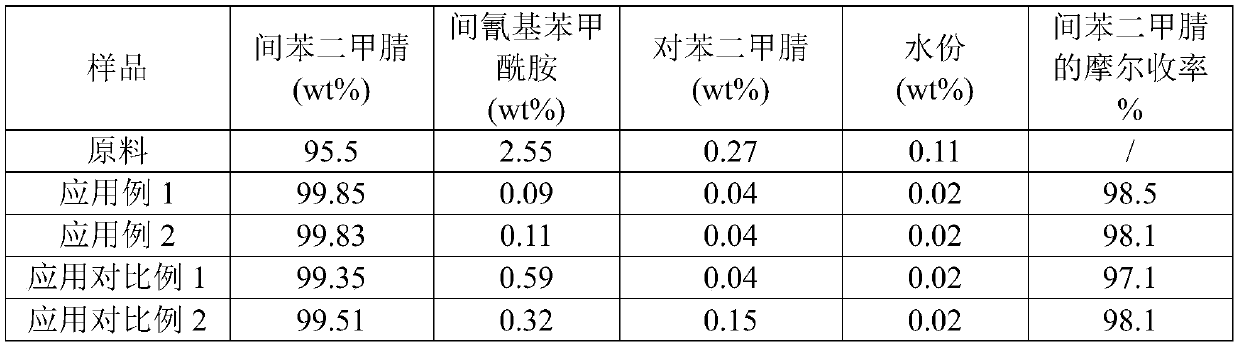

[0100] The present embodiment provides a kind of isophthalonitrile continuous rectifying purification device, such as figure 1 As shown, it includes a raw material supply unit, a purification unit and a product receiving unit connected in sequence, wherein,

[0101] The raw material supply unit includes: the raw material supply unit includes: a plunger type feed metering pump 1, a melting intermediate tank 2, a scraper evaporator 3, a first coke cutting tank 4 and a second coke cutting tank 5; wherein the plunger Type feed metering pump 1, melting intermediate tank 2 and scraper evaporator 3 are connected in sequence. The scraper evaporator is equipped with a stirring device inside, and the scraper is in the form of a limit hinge scraper. The bottom of the scraper evaporator 3 They are respectively connected to the tops of the first coke-cutting kettle 4 and the second coke-cutting kettle 5, and first valves are arranged on the connected pipelines, which are respectively valve...

Embodiment 2

[0105] This embodiment provides a kind of isophthalonitrile continuous rectification purification device, it comprises the raw material supply unit, purification unit and product receiving unit connected in sequence, wherein,

[0106] The raw material supply unit includes: a plunger type feed metering pump 1, a scraper evaporator 3, a first coke cutting tank 4 and a second coke cutting tank 5; wherein, the plunger type feed metering pump 1 and scraper evaporator The scraper evaporator is connected in turn, and the scraper evaporator is provided with a stirring device inside, and the scraper is in the form of a limit hinge scraper. The bottom of the scraper evaporator 3 is connected to the first coke cutting kettle 4 and the second coke cutting kettle 5 respectively. The tops are connected, and the first valves are set on the connected pipelines, which are respectively valve V3 and valve V6. The tops of the first coke-cut kettle 4 and the second coke-cut kettle 5 are also connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com