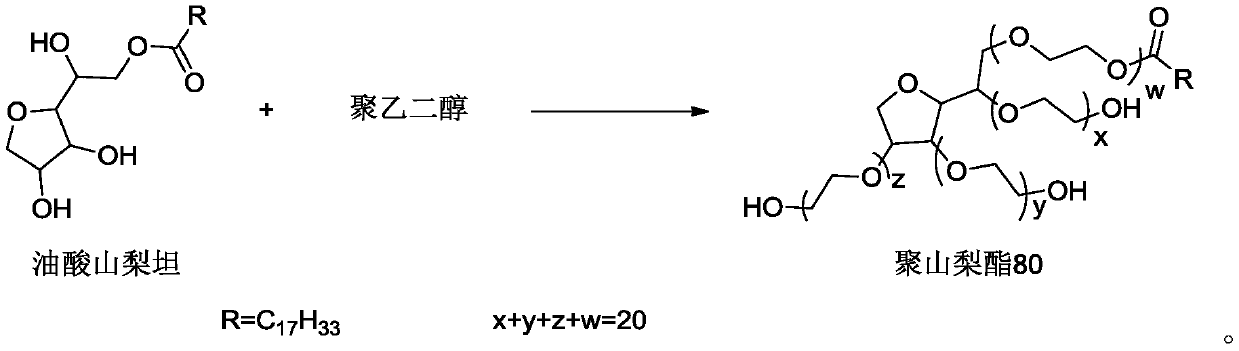

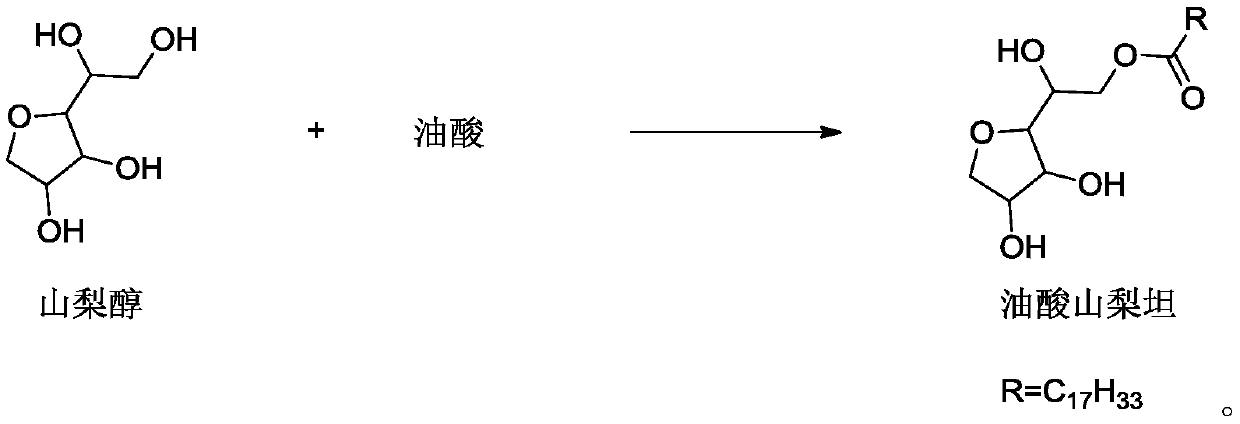

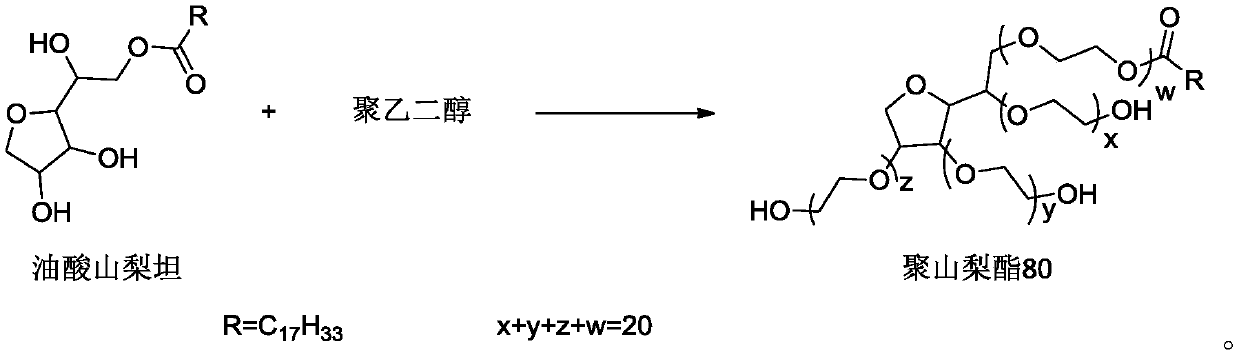

Polysorbate 80 for injection, and preparation method thereof

A technology of polysorbate and sorbitol, applied in the field of polysorbate 80 for injection and its preparation, can solve problems such as adverse reactions and allergic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

[0060] The synthesis of embodiment 1~11 polysorbate 80

Embodiment 1

[0062] Put 100 g of sorbitan oleate (Example 12), 100 g of polyethylene glycol 300 and 145 g of polyethylene glycol 400 into the reaction kettle, and add 0.1 g of sulfuric acid. React in vacuum at 115°C for 3.5h, and control the vacuum degree to be greater than 0.099Mpa. After the reaction is finished, the reaction solution is filtered with a 0.22um filter membrane and a plate-and-frame filter, and polysorbate 80 for injection is obtained after sterilization.

[0063] Through mass spectrometry detection, the obtained polysorbate 80 for injection does not contain impurities with a molecular weight greater than 2000.

[0064] According to nuclear magnetic detection, the ratio of methyl H of polysorbate 80 oleic acid for injection to methylene H of polyoxyethylene ether chain segment is 1:23.54. In theory, the ratio of methyl H of polysorbate 80 oleic acid to methylene H of polyoxyethylene ether segment is 3:40; since polysorbate 80 is a polymer, the ratio of the two will not be...

Embodiment 2

[0066] Put 400g of sorbitan oleate (Example 13), 400g of polyethylene glycol 300, 400g of polyethylene glycol 400 and 120g of polyethylene glycol 600 into the reaction kettle, and add 16.8g of phosphoric acid. React in vacuum at 125°C for 6.5h, and control the vacuum degree to be greater than 0.099Mpa. After the reaction, the reaction solution was filtered with a 0.22um filter membrane and a plate-and-frame filter, and polysorbate 80 for injection was obtained after sterilization. Its mass spectrum and NMR were basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com