Burnable poison assembly part postirradiation overall performance checking device and detection method

A technology for inspection devices and assembly parts, applied in the direction of measuring devices, mechanical devices, optical devices, etc., can solve the problems of no overall performance detection device, single function of detection equipment, high operation risk, etc., and achieve high measurement efficiency and scrape Less chance of rubbing and less chance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

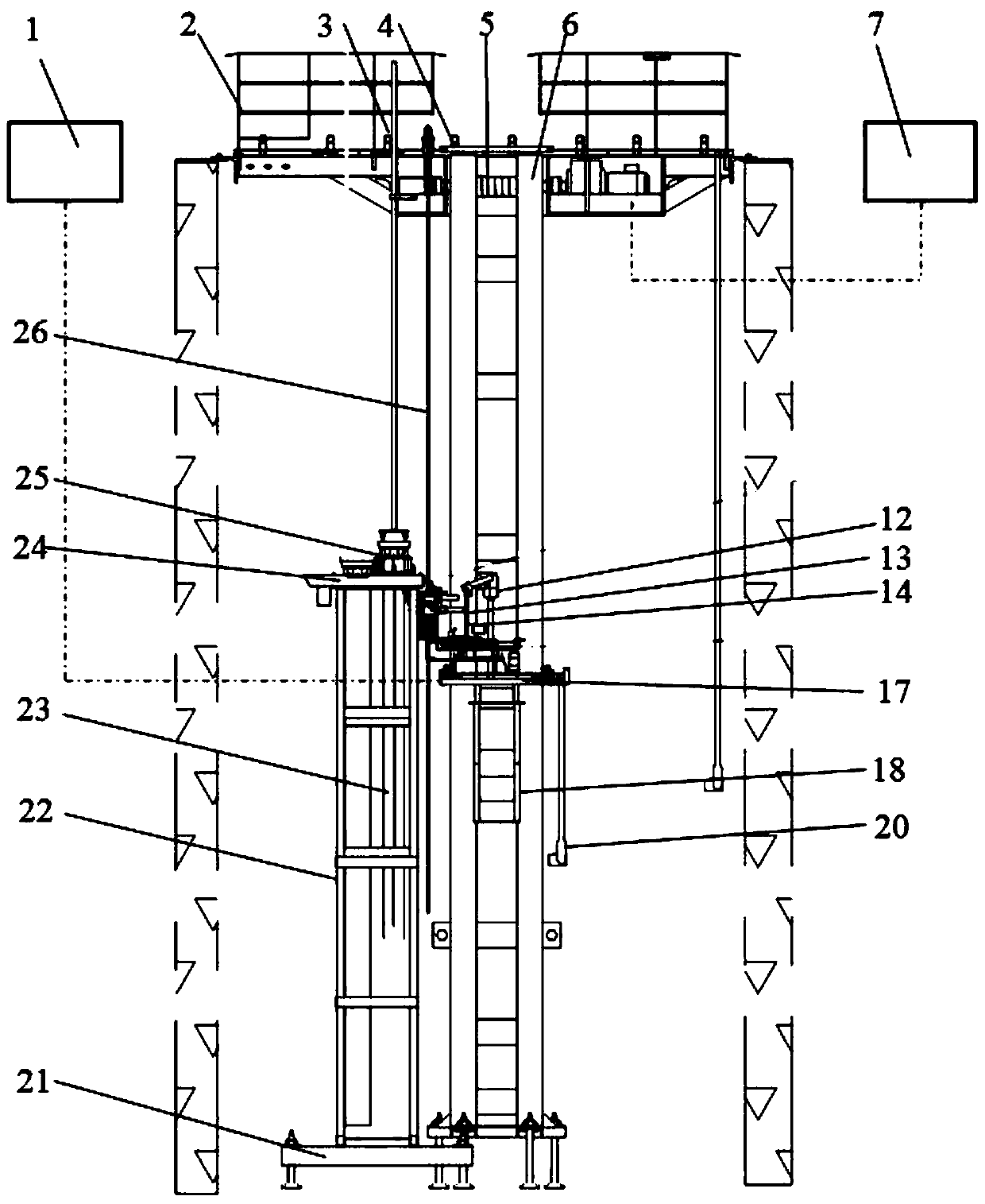

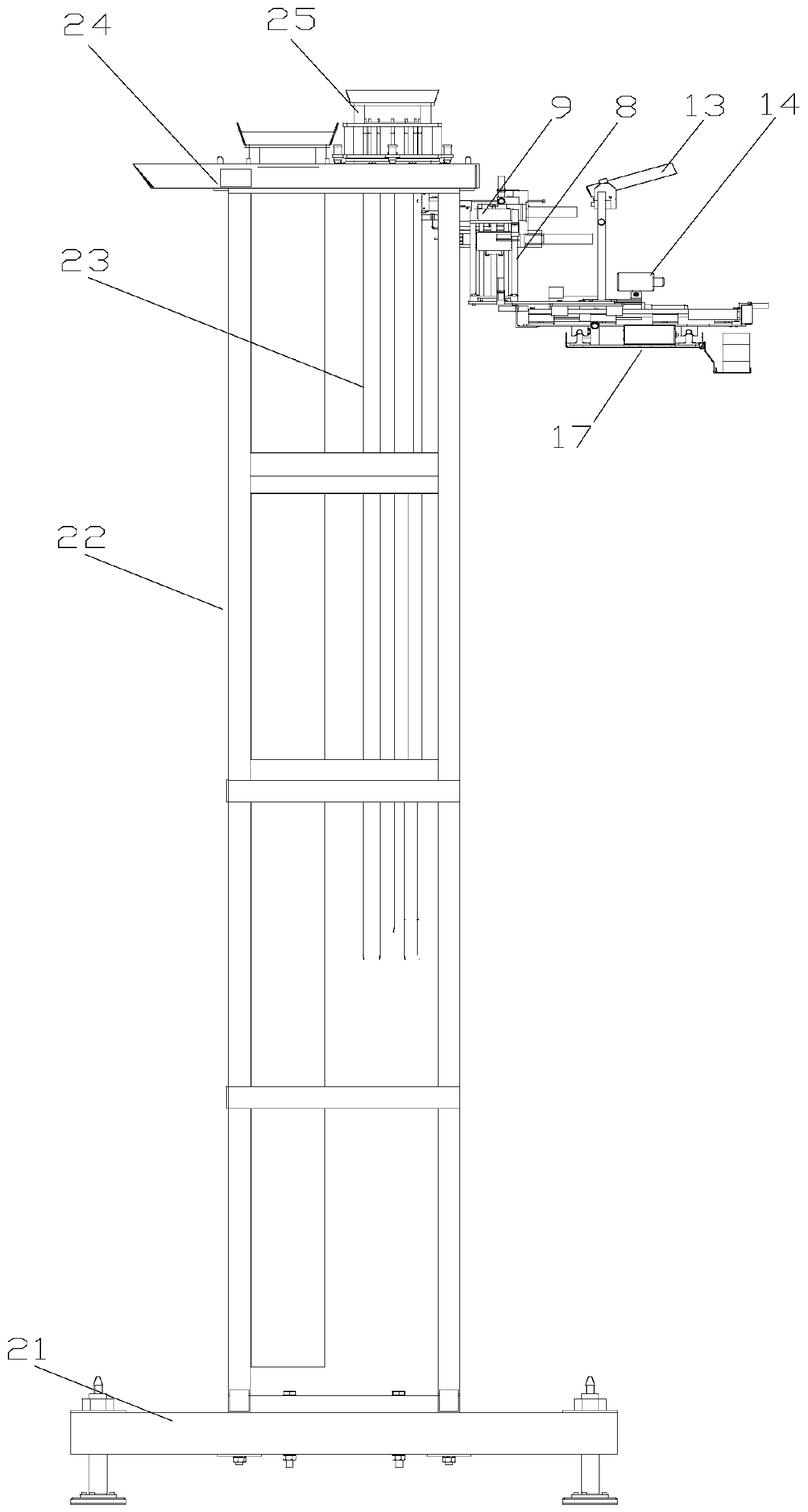

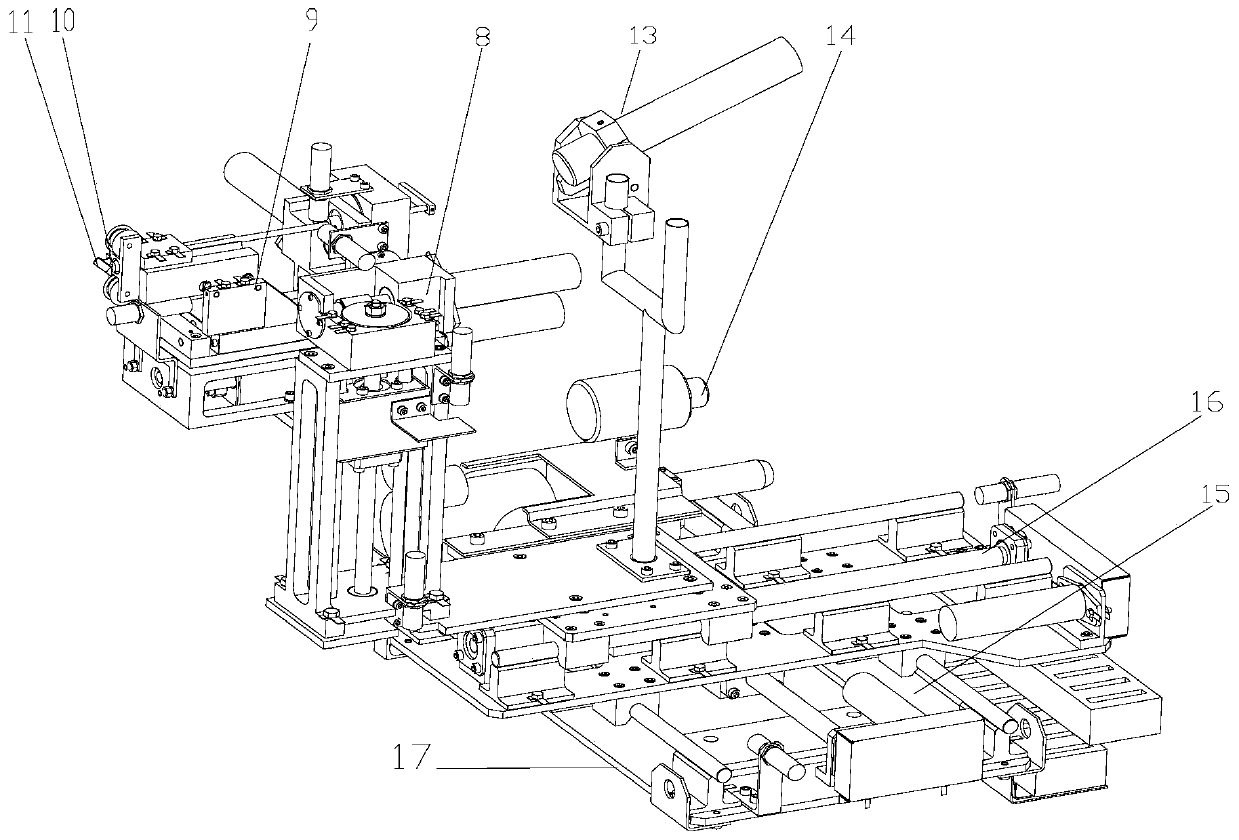

[0056] like Figure 1-Figure 4 The overall performance inspection device of a combustible poison assembly after irradiation is shown, including a bracket, a detection system and a main platform track 6, the bracket includes a lower base 21, and the lower base 21 is installed at the bottom of the well, and the lower base 21 is vertically provided with an upper base 22, the top of the upper base 22 is provided with a rotating mechanism 25, the top of the bracket is provided with a level measuring instrument 24, the rotating mechanism 25 is used to fix the assembly 23, and the rotating mechanism 25 is equipped with a rotating long handle 3, and a positioning hole matched with the rotating long handle 3 is arranged on the rotating mechanism 25. When rotating the rotating mechanism 25, the rotating long handle 3 can be inserted into the positioning hole for operation. The supports are arranged in parallel, and the main platform track 6 is provided with a moving trolley 18, which is...

Embodiment 2

[0058] A kind of detection method of integral performance inspection device after the irradiation of combustible poison assembly as described in embodiment 1, comprises the following steps:

[0059] 1) Install the assembly 23: use the level measuring instrument 24 to obtain the levelness of the top plane of the support frame, which must be less than 0.5 ゜, use the burnable poison grab of the nuclear power plant to pull the assembly 23 out of the fuel assembly and move it to the loading The top of the support in the well is positioned through the two positioning holes of the rotating mechanism 25. The burnable poison grabber sits on the top of the rotating mechanism 25, and the horizontality of the top plane of the support is obtained through the level measuring instrument 24 again, which needs to be less than 0.5°. The actuator on the tool inserts the assembly 23 into the rotation mechanism 25, removes the burnable poison gripper, inserts the rotating long handle 3 into the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com