A microfluidic chip spotting machine and spotting method

A microfluidic chip and spotting technology, applied in chemical instruments and methods, preparation of test samples, and laboratory containers, etc., can solve problems such as unmarkable, vibration, unfavorable continuous production, etc., to prevent missed detection Unqualified products, guaranteed sample quality, and beneficial to the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

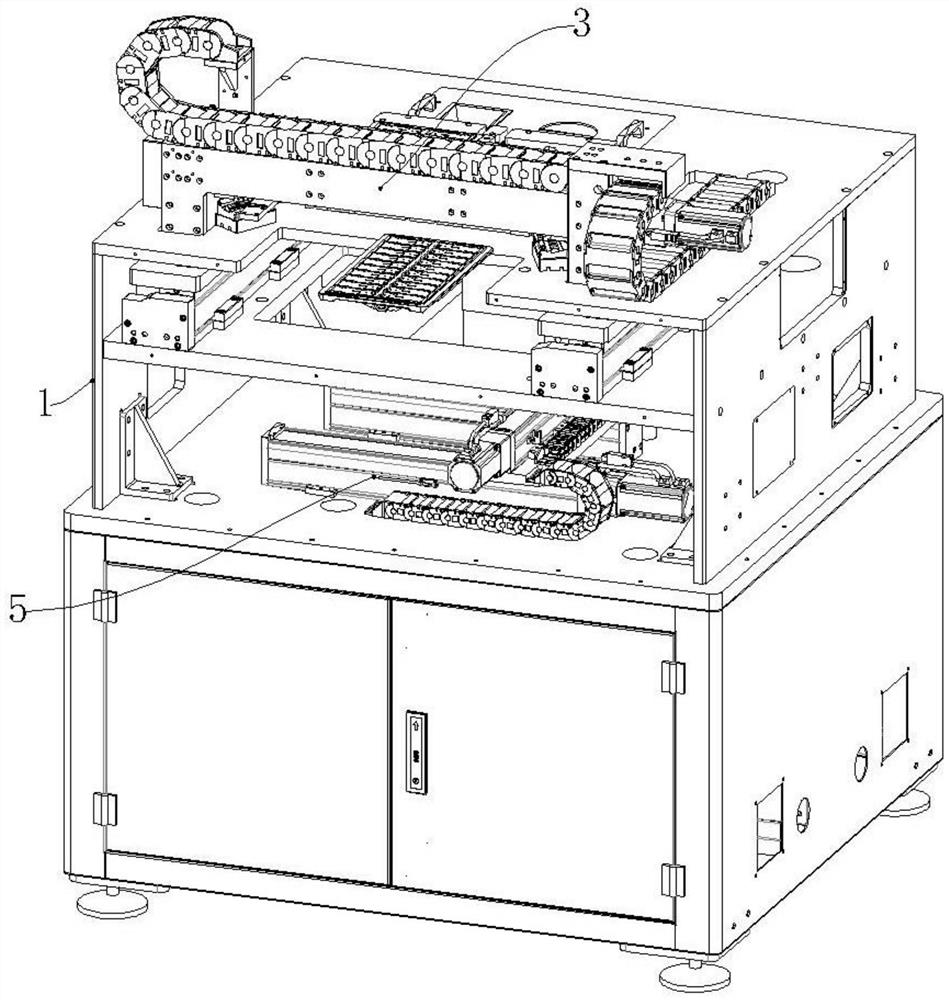

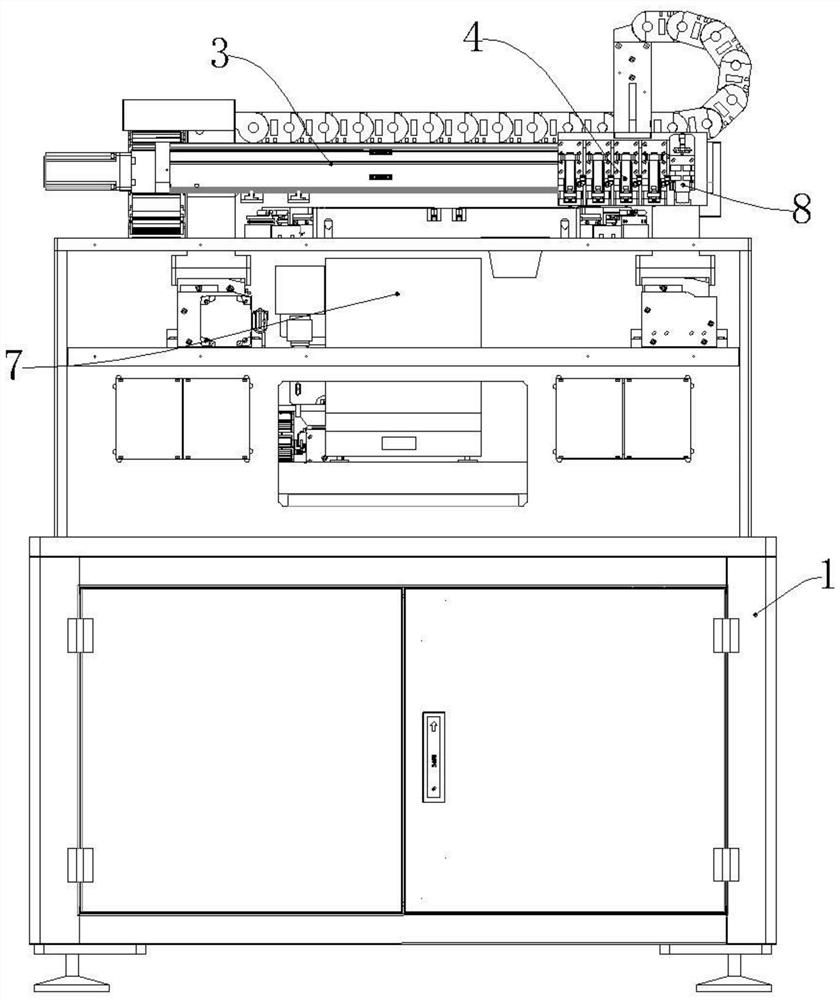

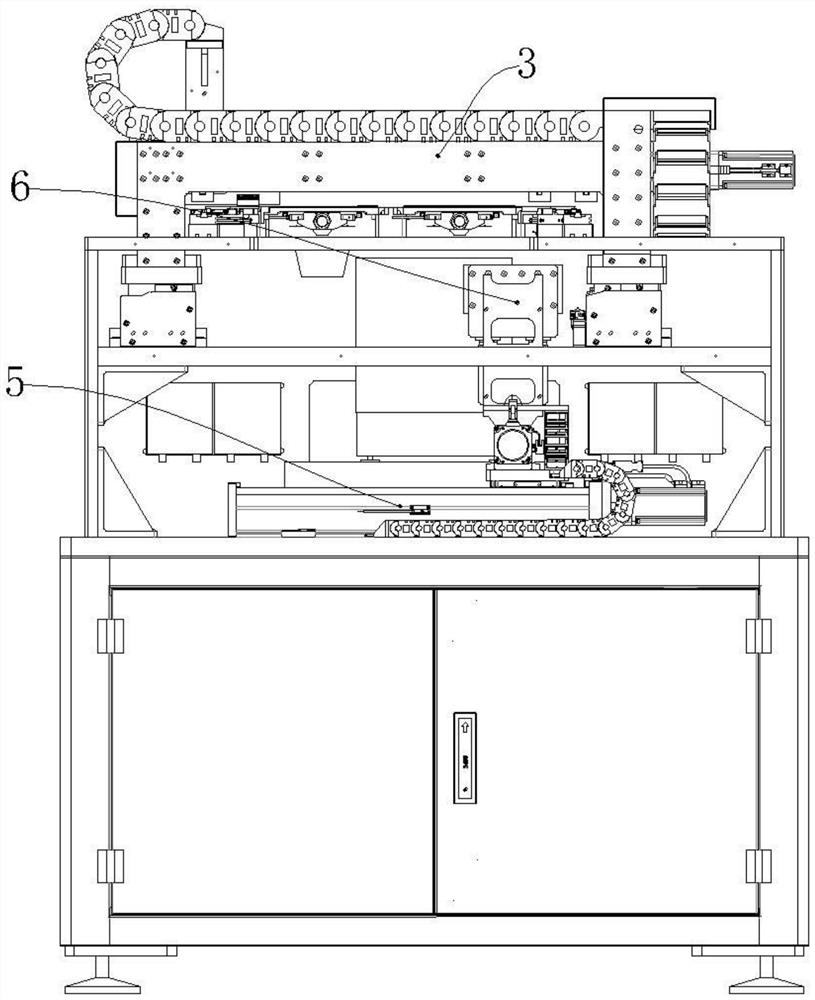

[0025] Such as Figure 1-Figure 6 As shown, a microfluidic chip pointing machine includes a frame 1, a fixture 2, a first xy linear module 3, a sampling head 4, a second xy linear module 5, a camera 6 and a weighing device 7, not Qualified product marking device 8 and waste liquid box 9.

[0026] Fixture 2 is set on Rack 1 as Figure 4 As shown, there are two sets of clamps 2, capable of clamping two chip storage trays 11 at the same time. The first xy linear module 3 is installed on the rack 1, such as Figure 5 As shown, both the sampling head 4 and the defective product marking device 8 are connected to the first xy linear module 3, and there are four sampling heads 4. In this embodiment, the defective product marking device 8 is an inkjet printer. The effect of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com