Water pollutant adsorbing material and preparation method thereof

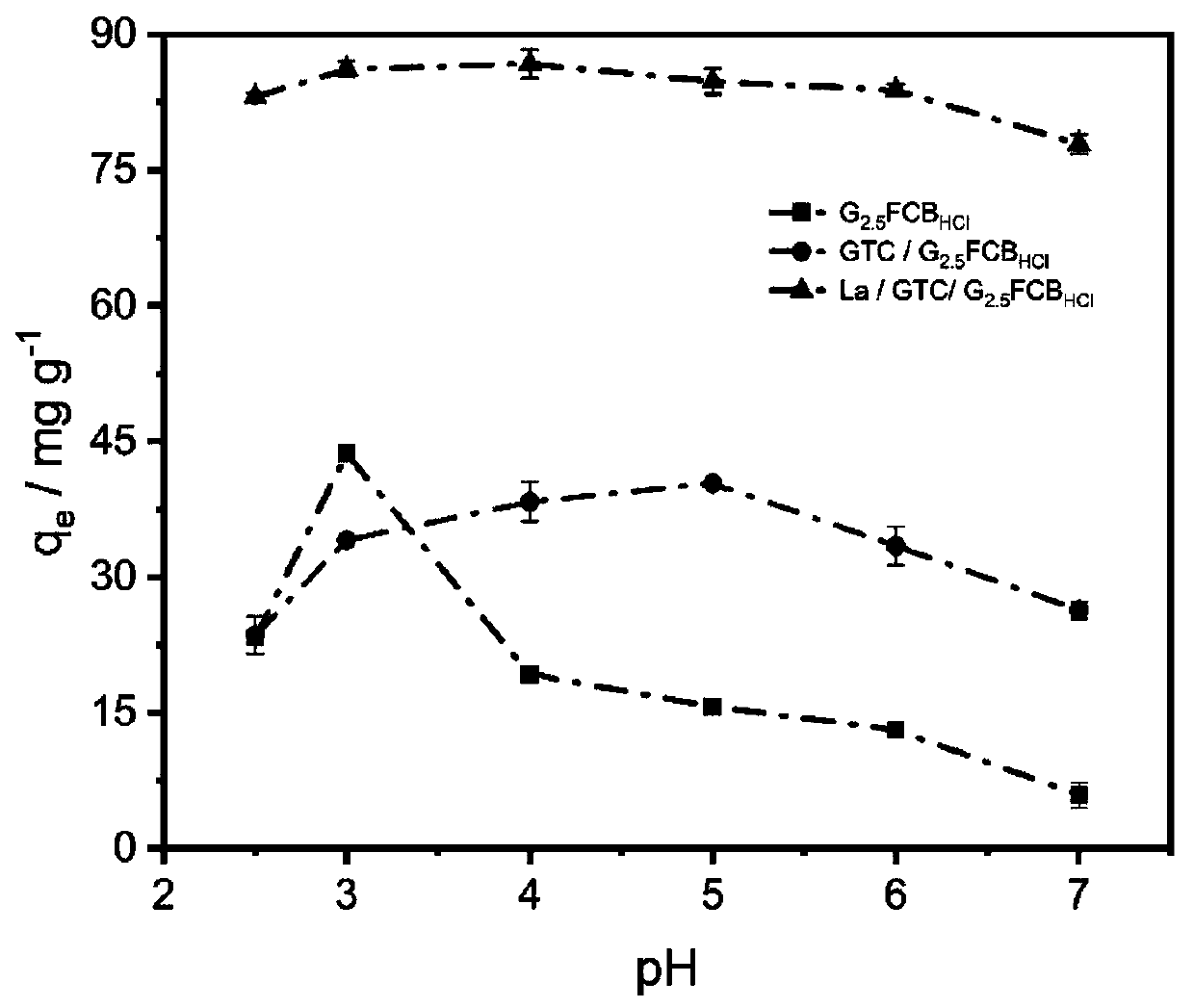

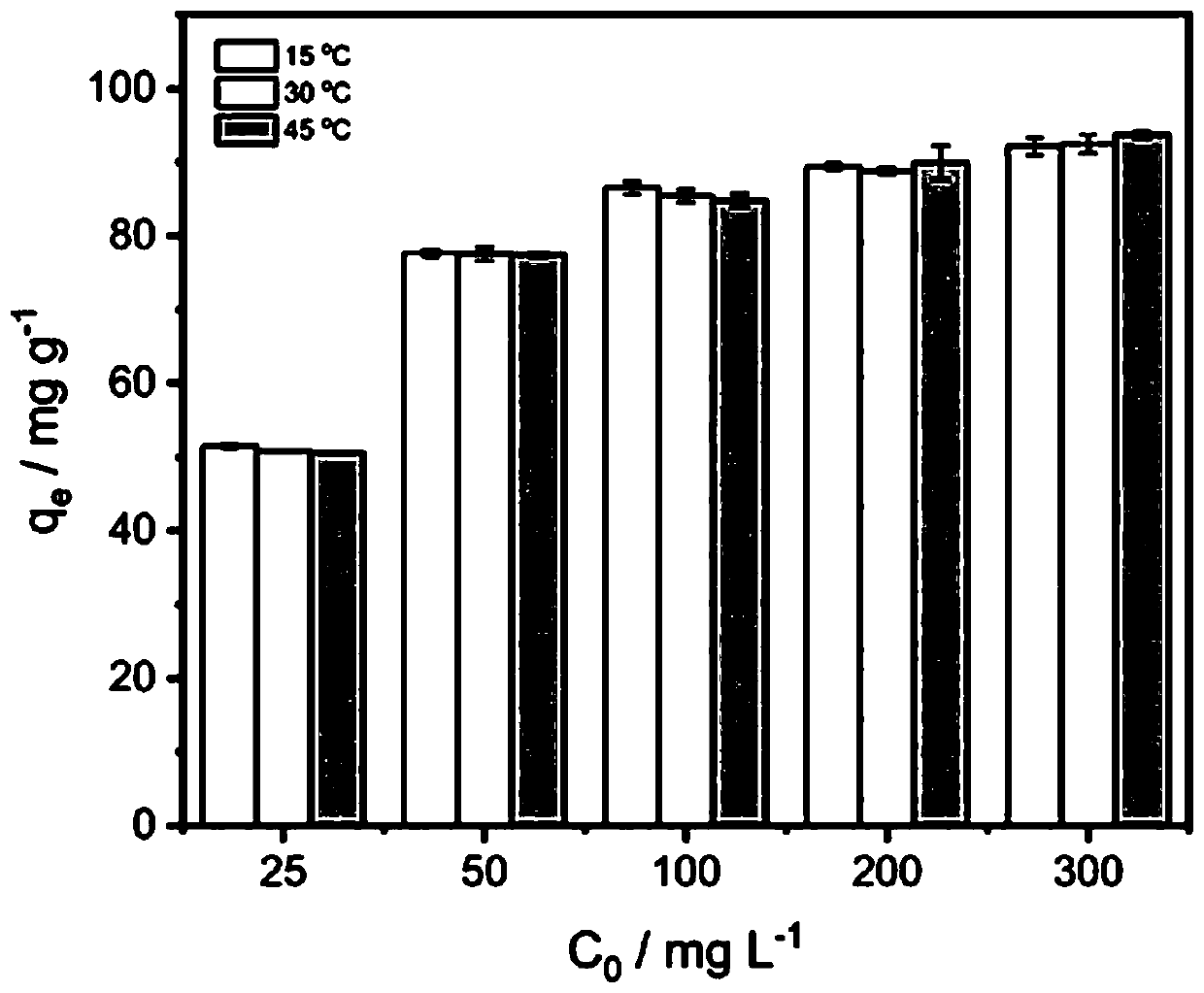

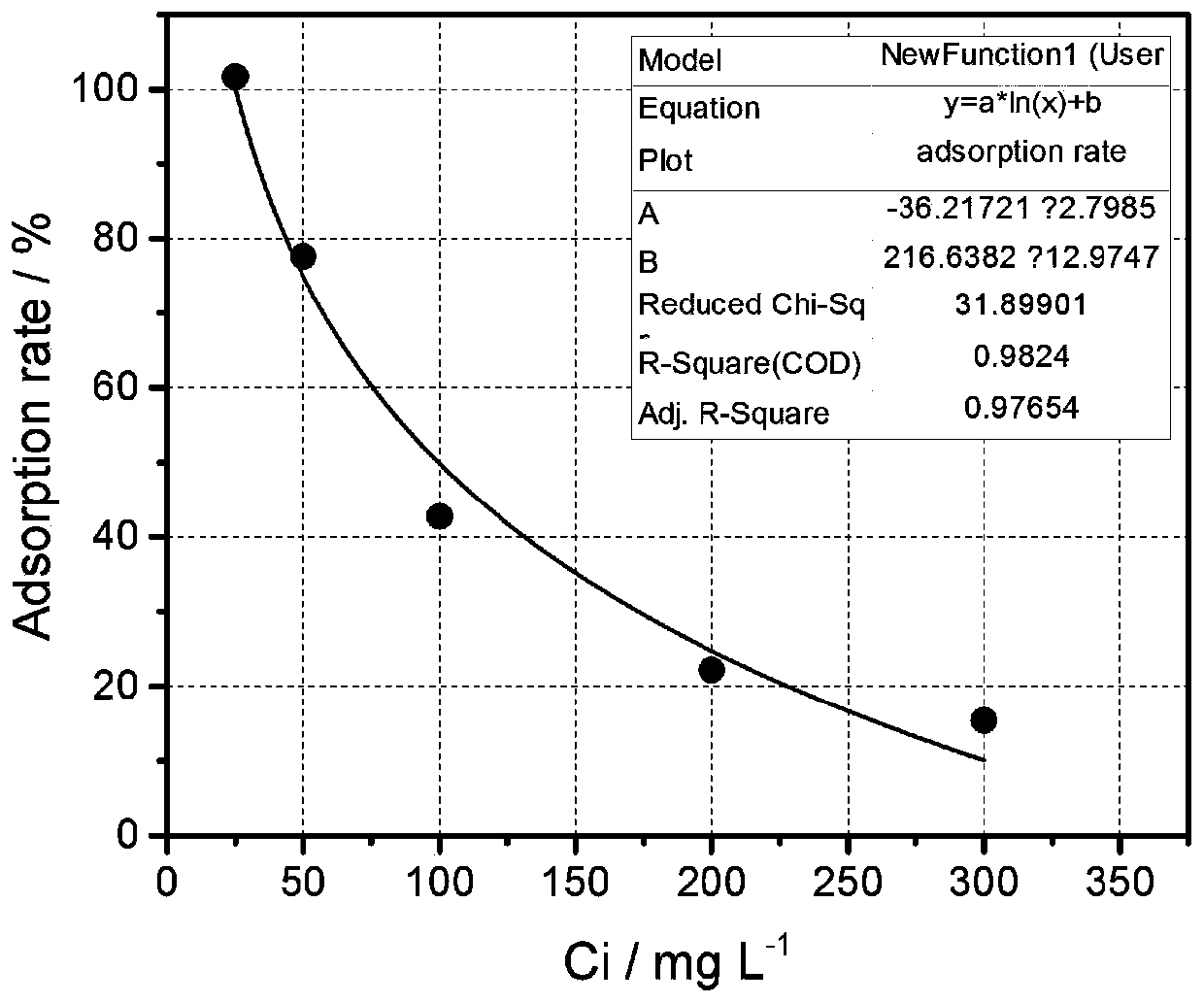

A water pollutant and adsorption material technology, applied in the production and synthesis of environmental pollutant removers, can solve the problems of disappearing adsorption capacity, low mechanical strength, unsatisfactory effect, etc., and achieve simplified operation, low cost, wide acid-base The effect of scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. The raw material for production is wheat straw. Firstly, the wheat straw was dried in an oven at 80° C., and then cut into 5 cm segments. Put 10 g of straw segments into the crucible, and use a tubular muffle furnace to feed N 2 Heated to 550°C at a heating rate of 10°C / min and held for 30 minutes. Then, turn off the heating and continue to turn on the N 2 to cool to room temperature. The prepared wheat straw biochar was ground to 150 μm. 10 g of ground wheat straw biochar was added to 1 L of 1M HCl and stirred overnight to remove ash, then washed with water, filtered, and vacuum-dried in an oven at 60 °C.

[0037] 2. Add 1 g of chitosan to 400 ml of 2% acetic acid solution, stir at 40° C. for 3 hours, then add 1 g of the above-mentioned wheat straw biochar. After continuing stirring for 1 hour, 1M NaOH solution was added to adjust the pH of the solution to 12, and stirring was continued at 40° C. for 2 hours. Afterwards, the mixture was filtered and washed wit...

Embodiment 2

[0047] 1. The raw material for production is landscaping pruning waste. The waste was first dried in an oven at 105°C, and then cut into 2 cm segments. Put 50 g of waste segments into the crucible, and use a tubular muffle furnace to feed N 2 Heated to 500°C at a heating rate of 5°C / min and held for 20 minutes. Then, turn off the heating and continue to turn on the N 2 to cool to room temperature. The produced biochar was ground to 100 μm. 50 g of ground wheat straw biochar was added to 5 L of 1M HCl and stirred overnight to remove ash, then washed with water, filtered, and vacuum-dried in an oven at 80 °C.

[0048] 2. Add 1g of chitosan to 400ml of 2% acetic acid solution, stir at 40°C for 2h, then add 1g of the above biochar. After stirring was continued for 1 hour, 1M NaOH solution was added to adjust the pH of the solution to 12, and stirring was continued at 40 °C for 3 hours. Afterwards, the mixture was filtered and washed with 4 L of water, and dried under vacuum ...

Embodiment 3

[0056] 1. The raw material for production is corn stalks. Firstly, corn stalks were dried in an oven at 100°C, and then cut into 5 cm segments. Put 10 g of straw segments into the crucible, and use a tubular muffle furnace to feed N 2 Heated to 550°C at a heating rate of 10°C / min and held for 30 minutes. Then, turn off the heating and continue to turn on the N 2 to cool to room temperature. The prepared corn stover biochar was ground to 150 μm. 10 g of ground wheat straw biochar was added to 1 L of 1M HCl and stirred overnight to remove ash, then washed with water, filtered, and vacuum-dried in an oven at 60 °C.

[0057] 2. Add 10 g of chitosan to 4000 ml of 2% acetic acid solution, stir at 40° C. for 3 hours, and then add 1 g of the above-mentioned corn stalk biochar. After continuing stirring for 1 hour, 1M NaOH solution was added to adjust the pH of the solution to 12, and stirring was continued at 40° C. for 2 hours. Afterwards, the mixture was filtered and washed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com