Preparation method of titanium dioxide/graphene flexible electrothermal film

A titanium dioxide and alkene flexible technology, applied in the field of electrothermal film preparation, can solve the problems of short service life, poor flexibility and high cost, achieve good electrothermal characteristics and improve the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of titanium dioxide / graphene flexible electrothermal film, comprising the following steps:

[0024] 1) Wash the PET film with deionized water and ethanol respectively, and dry it in the air.

[0025] 2) Weigh 10g of graphene and add 100ml of TiF with a concentration of 40mM 4 React in the solution at 60°C for 1 to 3 hours, wash and dry the precipitate with water and ethanol to obtain TiO 2 / Graphene powder.

[0026] 3) Weigh 9g of acrylic resin, 3g of propylene glycol methyl ether acetate, 1g of propylene glycol methyl ether and 27g of dipropylene glycol methyl ether in a reaction kettle, and heat at 100°C for 5 hours in a homogeneous reactor to obtain an acrylic resin solution .

[0027] 4) Weigh 10g of TiO 2 Graphene and carbon black (mass ratio is 1:3~5) add in the acrylic resin solution of 50g step 3), stir 1 hour, obtain TiO 2 / graphene slurry.

[0028] 5) The prepared TiO 2 / Graphene slurry is coated on PET film by screen printing, a...

Embodiment 1

[0031] 1) Wash the PET film with deionized water and ethanol respectively, and dry it in the air.

[0032] 2) Weigh 10g of graphene and add 100ml of TiF with a concentration of 40mM 4 The solution was reacted at 60°C for 3 hours, and the precipitate was washed and dried with water and ethanol to obtain TiO 2 / Graphene powder.

[0033] 3) Weigh 9g of acrylic resin, 3g of propylene glycol methyl ether acetate, 1g of propylene glycol methyl ether and 27g of dipropylene glycol methyl ether in a reaction kettle, and heat at 100°C for 5 hours in a homogeneous reactor to obtain an acrylic resin solution .

[0034] 4) Weigh 10g of TiO 2 Graphene and carbon black (mass ratio is 1:3) add step 3) in the acrylic resin solution, stir 1 hour, obtain TiO 2 / graphene slurry.

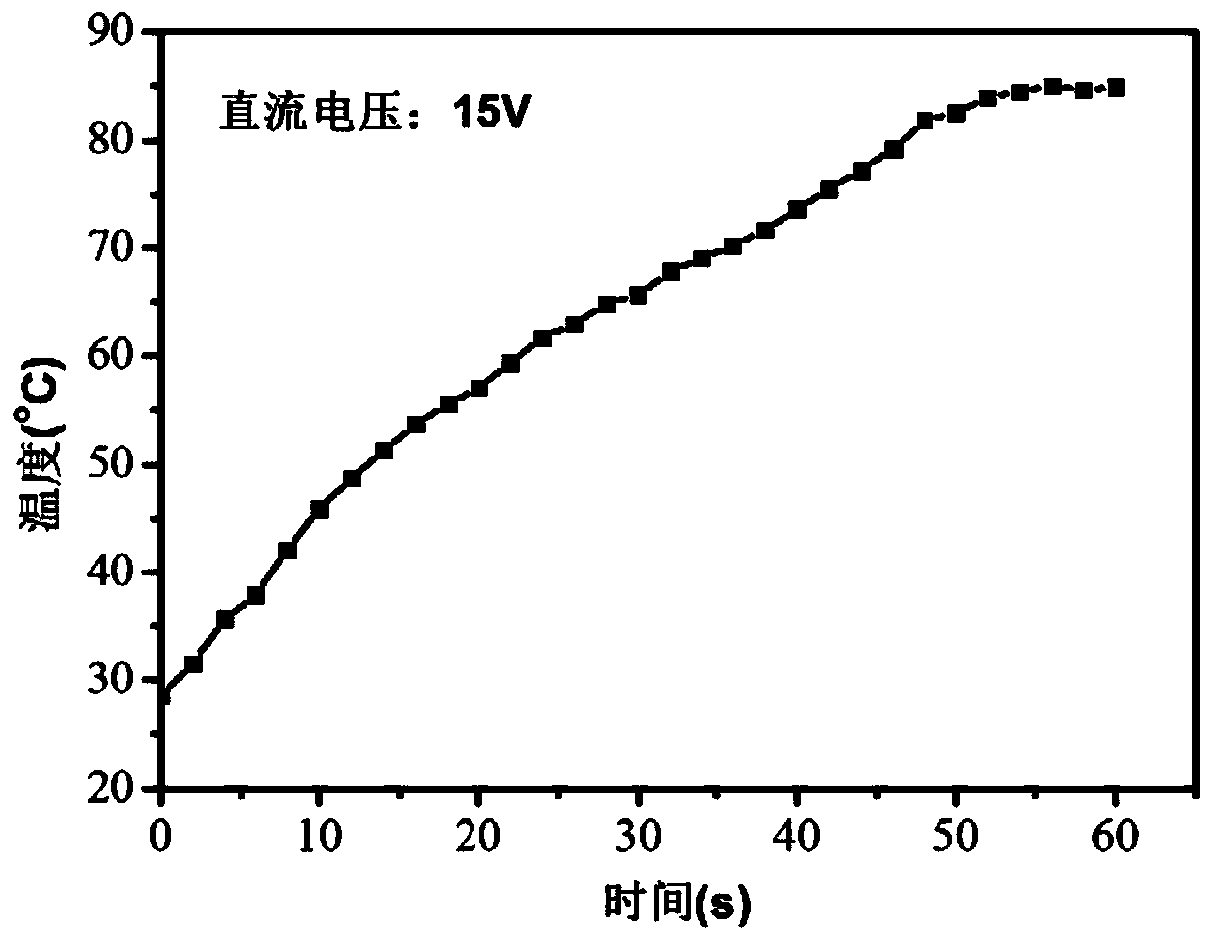

[0035] 5) The prepared TiO 2 / Graphene slurry is coated on PET film by screen printing, and after drying at 120°C for 10 minutes, TiO 2 / Graphene flexible electrothermal film. After applying a voltage of 15V...

Embodiment 2

[0037] 1) Wash the PET film with deionized water and ethanol respectively, and dry it in the air.

[0038] 2) Weigh 10g of graphene and add 100ml of TiF with a concentration of 40mM 4 The solution was reacted at 60°C for 3 hours, and the precipitate was washed and dried with water and ethanol to obtain TiO 2 / Graphene powder.

[0039] 3) Weigh 9g of acrylic resin, 3g of propylene glycol methyl ether acetate, 1g of propylene glycol methyl ether and 27g of dipropylene glycol methyl ether in a reaction kettle, and heat at 100°C for 5 hours in a homogeneous reactor to obtain an acrylic resin solution .

[0040] 4) Weigh 10g of TiO 2 Graphene and carbon black (mass ratio is 1:4) add step 3) in the acrylic resin solution, stir 1 hour, obtain TiO 2 / graphene slurry.

[0041] 5) The prepared TiO 2 / Graphene slurry is coated on PET film by screen printing, and after drying at 120°C for 10 minutes, TiO 2 / Graphene flexible electrothermal film. After applying a voltage of 15V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com