Preparation method of Ti3C2 powder

A technology of powder and ceramic powder, which is applied in the field of Ti3C2 powder preparation, can solve the problems of different powder process performance and undisclosed drying process, and achieve the effects of low cost, time-saving preparation process, and uniform fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

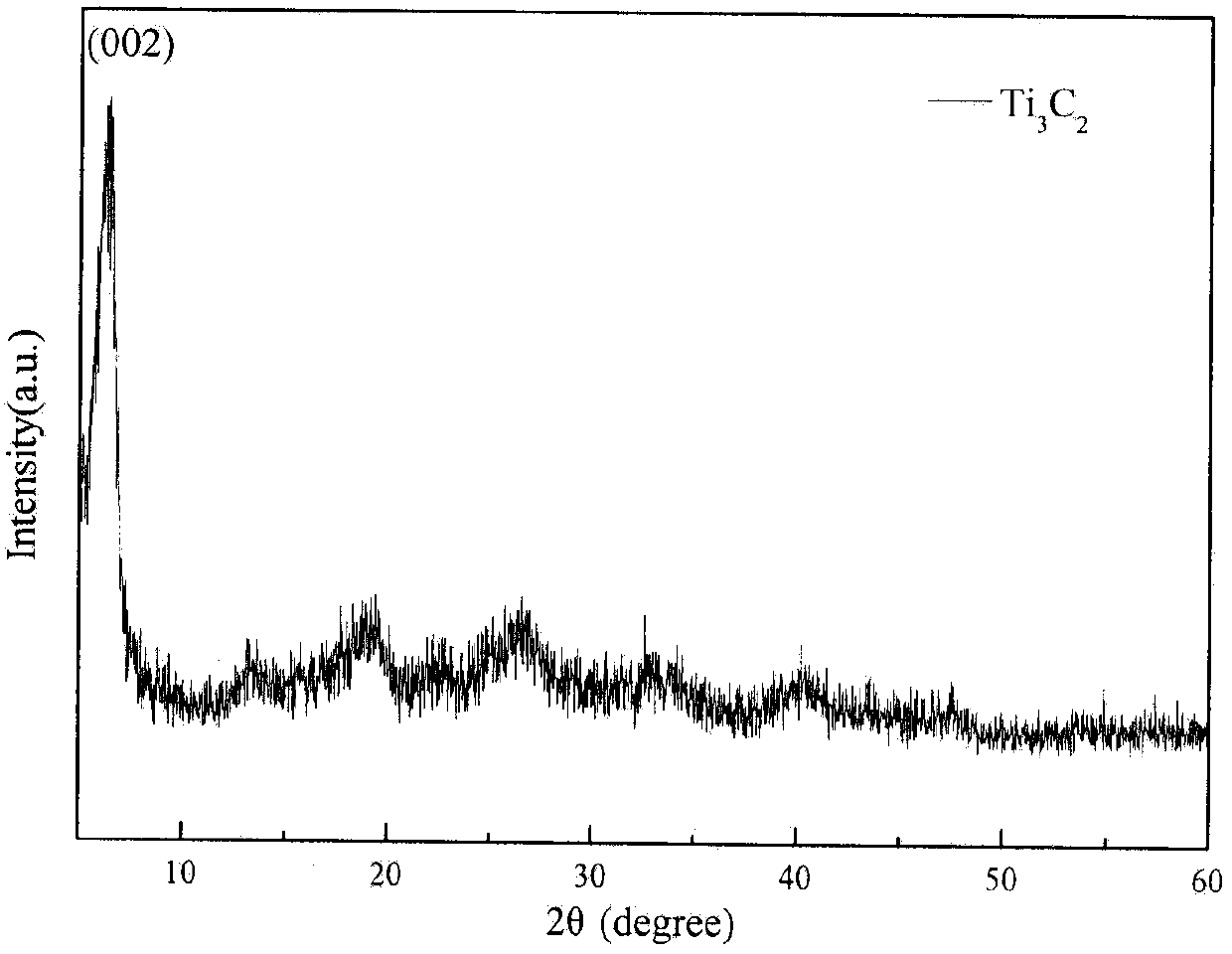

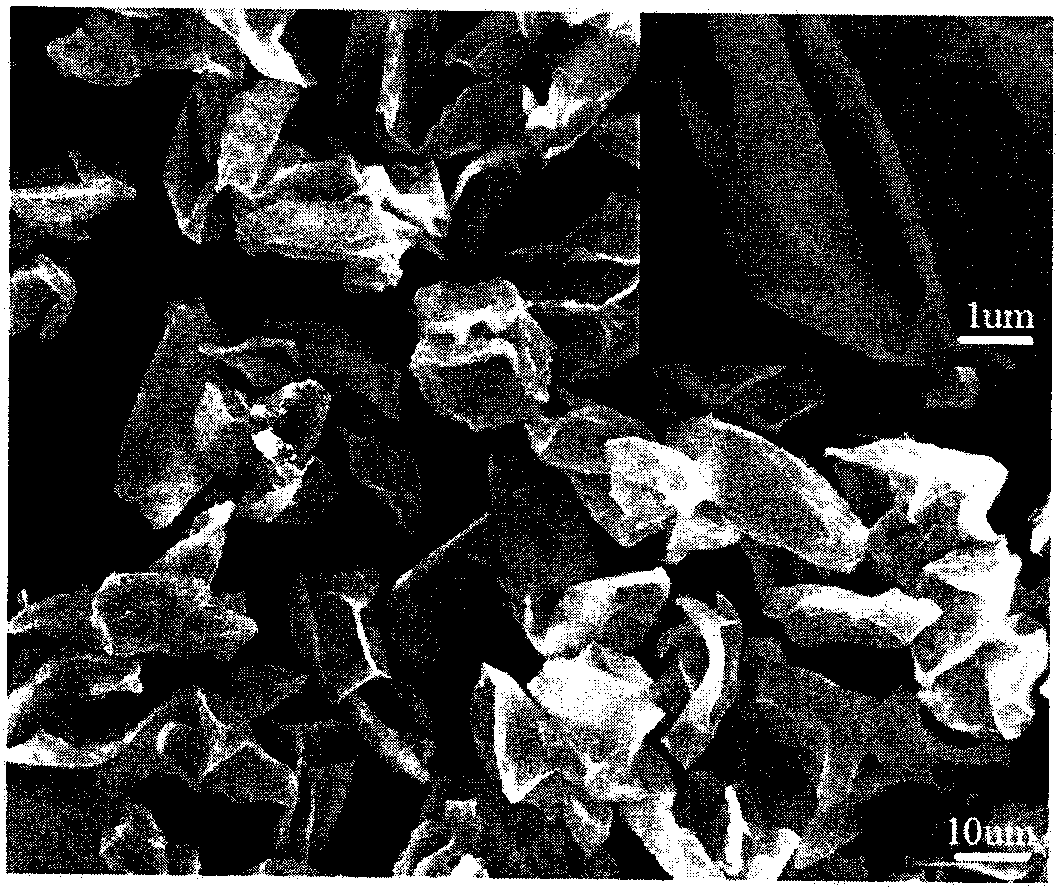

Embodiment 1

[0027] Using 400 mesh Ti 3 AlC 2 The ceramic powder is used as the raw material, using 36% concentration of hydrochloric acid and LiF mixed etching, hydrochloric acid and LiF and Ti 3 AlC 2 The ratio of ceramics is: 30:1.89:1.5. Corrosion in a water bath at 40°C for 24 hours, the corrosion product was washed with deionized water and centrifuged until the supernatant was neutral; the MXene powder was mixed with deionized water again and dispersed by ultrasonic vibration for 1 hour, and the liquid after ultrasonic vibration was manually oscillated 20min, again dispersed by ultrasonic vibration for 1h, and then centrifuged for 3min to obtain Ti 3 C 2 Suspension of nanosheets. Put 200ml of the suspension into a small spray dryer for rapid drying to prepare uniform and few-layered Ti 3 C 2 For flake powder, the air inlet temperature is 180°C, the air outlet temperature is 80°C, and the feed rate is 300ml / h. The bulk density of the prepared powder is 0.197g / ml.

Embodiment 2

[0029] Using 400 mesh Ti 3 AlC 2 The ceramic powder is used as the raw material, using 36% concentration of hydrochloric acid and LiF mixed etching, hydrochloric acid and LiF and Ti 3 AlC 2 The ratio of ceramics is: 30:1.89:1.5. Corrosion in a water bath at 40°C for 24 hours, the corrosion product was washed with deionized water and centrifuged until the supernatant was neutral; the MXene powder was mixed with deionized water again and dispersed by ultrasonic vibration for 1 hour, and the shaken liquid was shaken manually for 20 minutes , disperse again by ultrasonic vibration for 1 h, and then centrifuge for 3 min to obtain nanosheet Ti 3 C 2 suspension. Inhale 200ml of the suspension into a small spray dryer for rapid drying, resulting in the preparation of uniform and few-layered Ti 3 C 2 For flake powder, the air inlet temperature is 180°C, the air outlet temperature is 80°C, and the feed rate is 400ml / h. The bulk density of the prepared powder is 0.213g / ml.

Embodiment 3

[0031] Using 400 mesh Ti 3 AlC 2 The ceramic powder is used as the raw material, using 36% concentration of hydrochloric acid and LiF mixed etching, hydrochloric acid and LiF and Ti 3 AlC 2 The ratio of ceramics is: 30:1.89:1.5. Corrosion in a water bath at 40°C for 24 hours, the corrosion product was washed with deionized water and centrifuged until the supernatant was neutral; the MXene powder was mixed with deionized water again and dispersed by ultrasonic vibration for 1 hour, and the shaken liquid was shaken manually for 20 minutes , disperse again by ultrasonic vibration for 1h, and then centrifuge for 3min to get nanosheets of Ti 3 C 2suspension. Inhale 200ml of the suspension into a small spray dryer for rapid drying to prepare uniform and few-layered Ti 3 C 2 For flake powder, the air inlet temperature is 180°C, the air outlet temperature is 80°C, and the feed rate is 500ml / h. The bulk density of the prepared powder is 0.224g / ml.

[0032] The Ti that embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com