Preparation method of composite anticorrosive coating for inner wall of garbage incinerator

A waste incinerator and anti-corrosion technology, which is applied in coating, metal material coating process, liquid chemical plating and other directions, can solve the problem of high price, achieve the effect of cost utilization and improve chlorine corrosion resistance

Active Publication Date: 2019-12-27

JIANGXI SCI & TECH NORMAL UNIV

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this product is expensive. In order to further improve its corrosion resistance and ensure the maximum utilization of capital costs, the present invention proposes Al 2 o 3 / ZrO 2 / Preparation method of Inconel625 composite anti-corrosion coating, in order to further improve its corrosion resistance

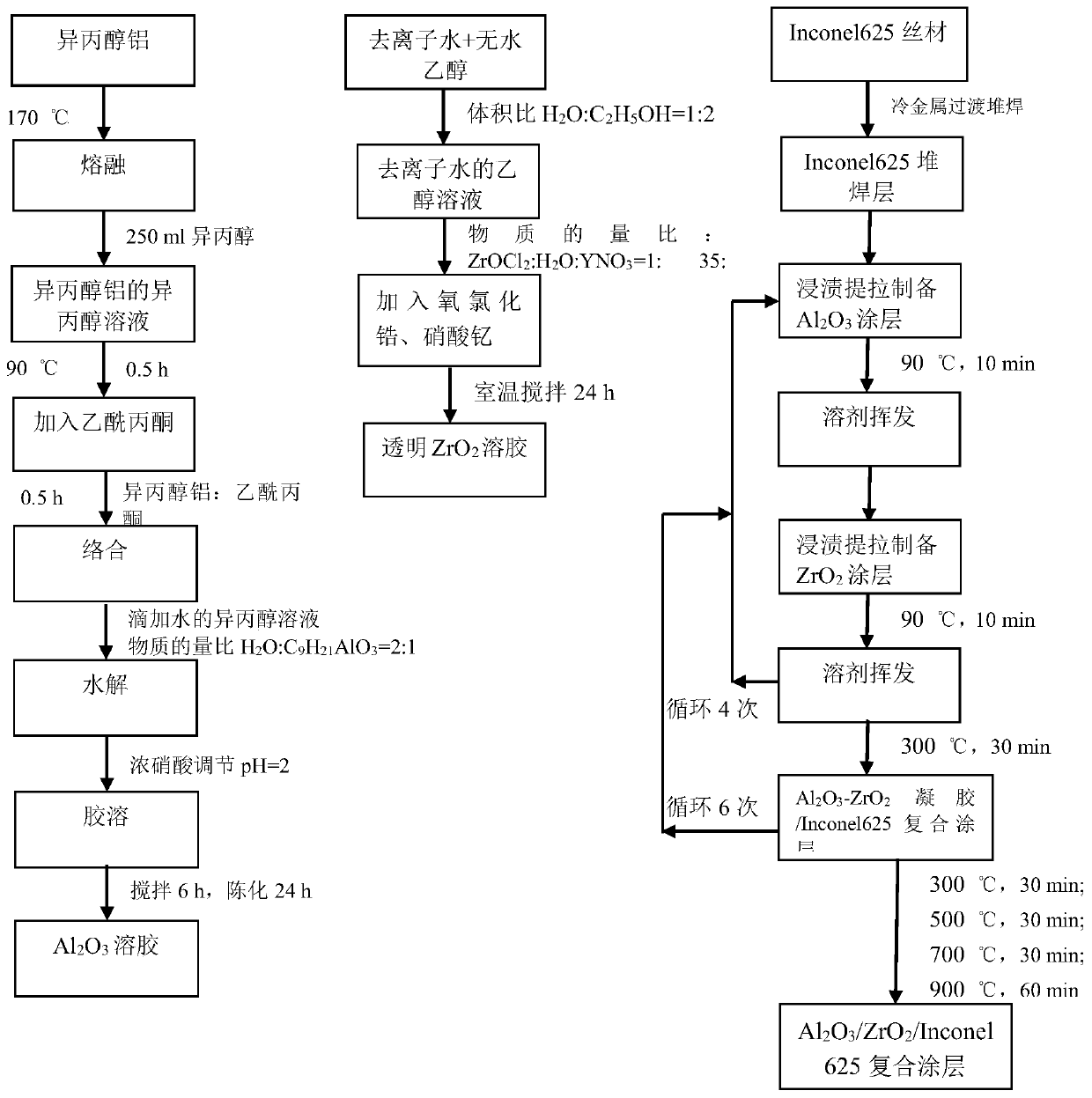

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] First, polish the 20x20x1.2cm Q235 plate with 80#, 200#, 600# sandpaper, remove the surface scale, wash with ethanol, and dry naturally.

[0028] Secondly, Inconel625 wire is surfacing welded on the surface of Q235 steel by cold metal oversurfacing process. Cut the surfacing sample into 10x10x12mm small samples by wire cutting, and set aside.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

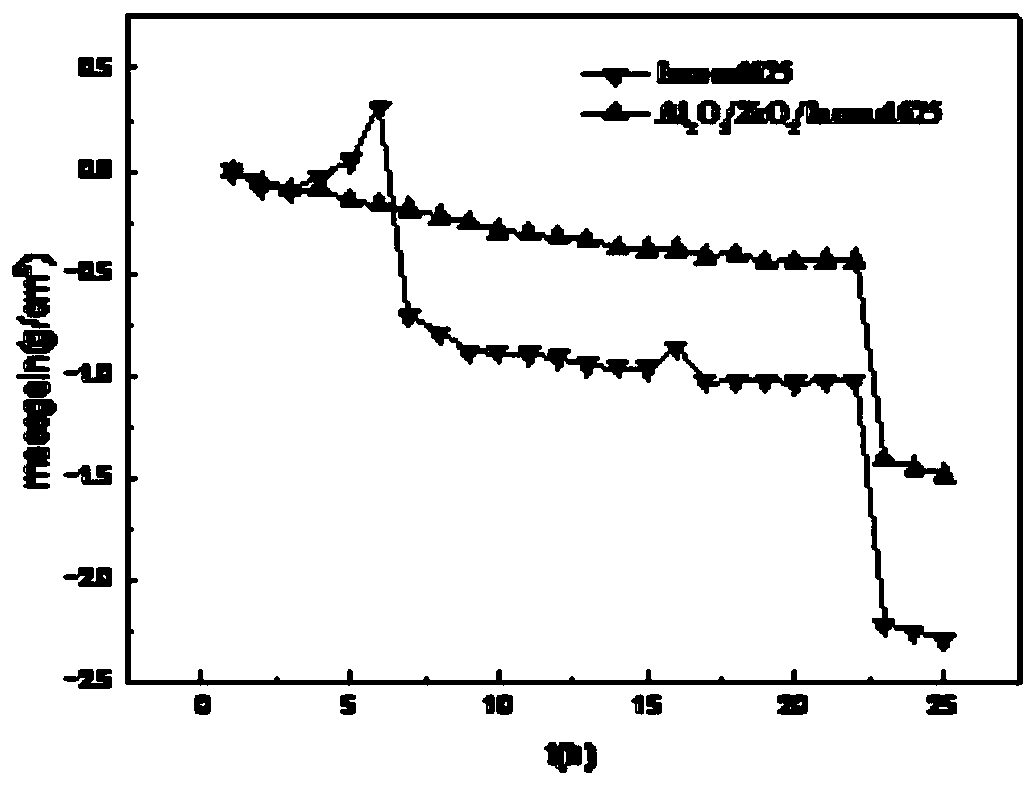

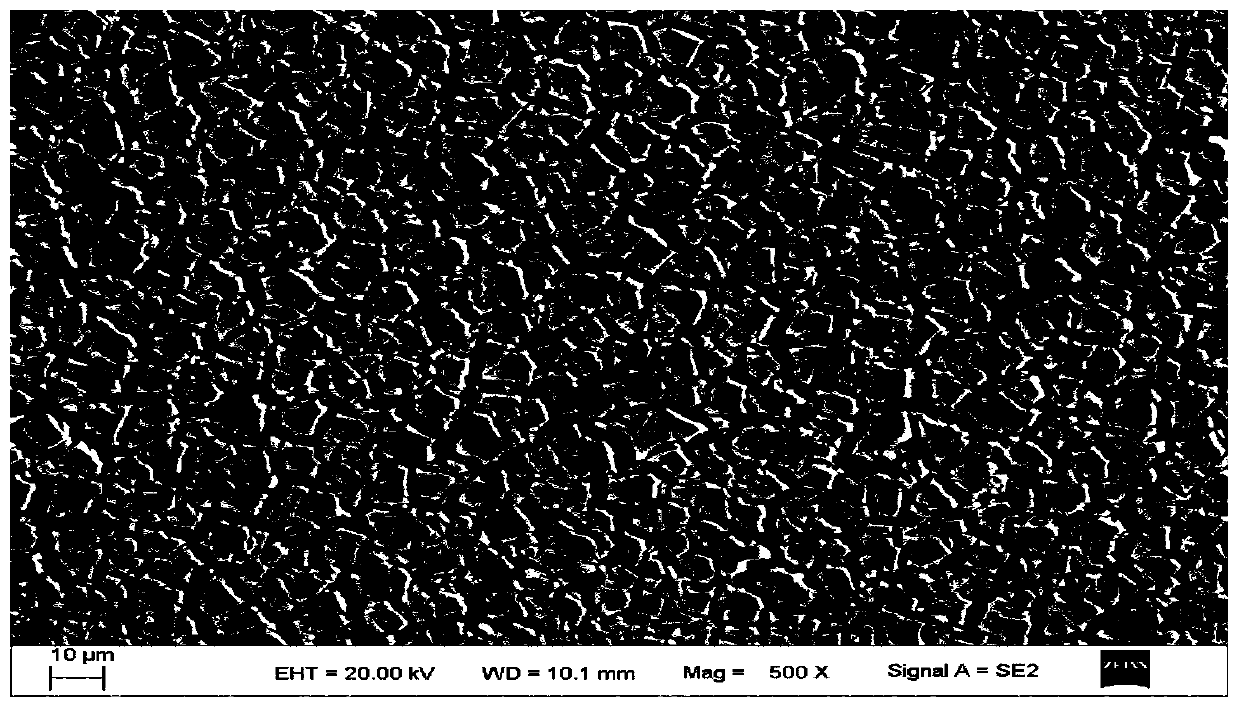

The invention discloses a preparation method of a Al2O3 / ZrO2 / Inconel625 composite anticorrosive coating for the inner wall of a garbage incinerator. The preparation method is characterized in that a Al2O3 / ZrO2 / Inconel625 composite coating is prepared on the surface of Q235 steel by taking an Inconel625 wire, zirconium oxychloride, aluminum isopropoxide, diacetone, yttrium nitrate, isopropyl alcohol, anhydrous ethanol and the like as initial raw materials and combining a cold metal transition surfacing technology with a sol-gel method, so that the fused salt corrosion resistance of a matrix material is improved. The analysis of XRD and SEM results shows that a uniform cracked micron-thick Al2O3 / ZrO2 / Inconel625 composite coating is prepared on the surface of a Q235 alloy by adopting the technology; and after a sample is subjected to NaCl fused salt corrosion at 900 DEG for 24 hours, corrosion kinetics data obtained by adopting a weight loss method show that compared with a single Inconel625 coating sample, the Al2O3 / ZrO2 / Inconel625 composite coating has the advantages that weight loss of the sample is remarkably reduced, and corrosion resistance of the matrix material in fused salt is improved.

Description

technical field [0001] The invention relates to the technical field of anti-corrosion coating design on the inner wall of a garbage incinerator, in particular to an Al coating applied to a garbage incinerator. 2 o 3 / ZrO 2 / Inconel625 composite anti-corrosion coating preparation method. Background technique [0002] The problem of garbage disposal has become increasingly serious. It is an imperative development trend to properly dispose of garbage and obtain resource recycling. Waste incineration power generation, as an environmentally friendly, energy-saving and resource-reusing process, has attracted people's attention. Chlorine corrosion, sulfur corrosion and other phenomena on the inner wall of heat exchangers and other components in waste incineration power generation equipment seriously affect the service life of the incinerator and the safety of working conditions. Inconel625 has good corrosion resistance, especially resistance to chlorine corrosion and pitting cor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C18/12B23P15/00

CPCB23P15/00C23C18/1216C23C18/1241C23C18/1254

Inventor 白凌云向军淮陈土春江龙发

Owner JIANGXI SCI & TECH NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com