(0-70mpa) pressure adjustable tracer plunger pump

A technology of pressure regulation and plunger pump, applied in the direction of pump, pump element, pump control, etc., it can solve the problem that it is impossible to clearly understand whether the tracer is all injected into the formation, the material in the water tank and the material tank cannot be extracted in time, and the solid Impurity generation and other problems, to achieve the effect of good practical value, good sealing and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

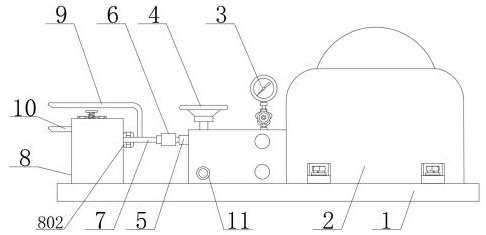

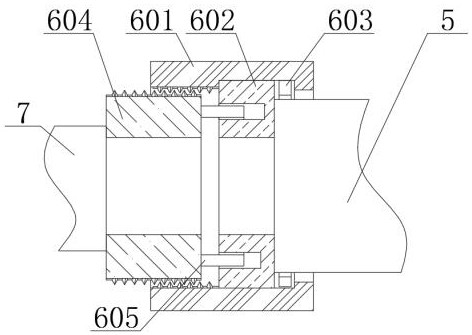

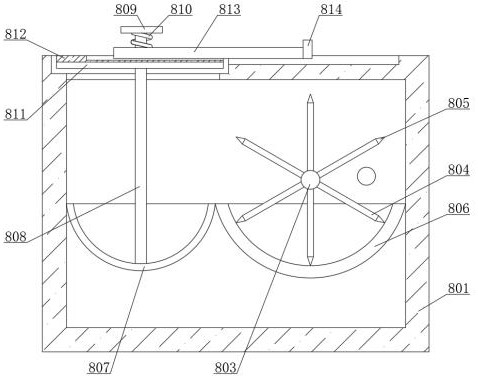

[0024] See figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The present invention provides a technical solution:

[0025]Tracer adjustable pressure piston, comprises a base 1, adjustable pressure plunger pump 2, the pressure indicated in Table 3 and the pressure regulator valve 4, the right end surface of the base 1 is fixedly connected with a pressure adjustable plunger pump 2, the pressure adjustable piston end face is fixedly connected with a pressure regulating valve in an approximate profile 4 and 3 in table 2 indicates the pressure, the pressure indicator can be clearly seen in table 3 the size of the pump body pressure by the pressure regulating valve 4 can adjust the pump body pressure, adjustable pressure plunger pump 2 fixed to the left end surface 5 has an input tube, the input tube 5 is fixedly connected to a left end surface of the connecting means 6, connecting means 6 comprises a rotatable tube 601, connecting ring 602, the rubber pad 603 and the rotary cylind...

Embodiment 2

[0029] See figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The present invention provides a technical solution:

[0030] Tracer adjustable pressure piston, comprises a base 1, adjustable pressure plunger pump 2, the pressure indicated in Table 3 and the pressure regulator valve 4, the right end surface of the base 1 is fixedly connected with a pressure adjustable plunger pump 2, the pressure adjustable piston end face is fixedly connected with a pressure regulating valve in an approximate profile 4 and 3 in table 2 indicates the pressure, the pressure indicator can be clearly seen in table 3 the size of the pump body pressure by the pressure regulating valve 4 can adjust the pump body pressure, adjustable pressure plunger pump 2 fixed to the left end surface 5 has an input tube, the input tube 5 is fixedly connected to a left end surface of the connecting means 6, connecting means 6 comprises a rotatable tube 601, connecting ring 602, the rubber pad 603 and the rotary cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com