Environment-friendly dust suppressant containing modified hyperbranched polyester and preparation method thereof

A technology of hyperbranched polyester and dust suppressant, applied in chemical instruments and methods, other chemical processes and other directions, can solve the problems of poor flexibility of the dust suppressant, environmental pollution, etc., and achieves good dust suppression effect, easy operation, The effect of reducing dust pollution and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

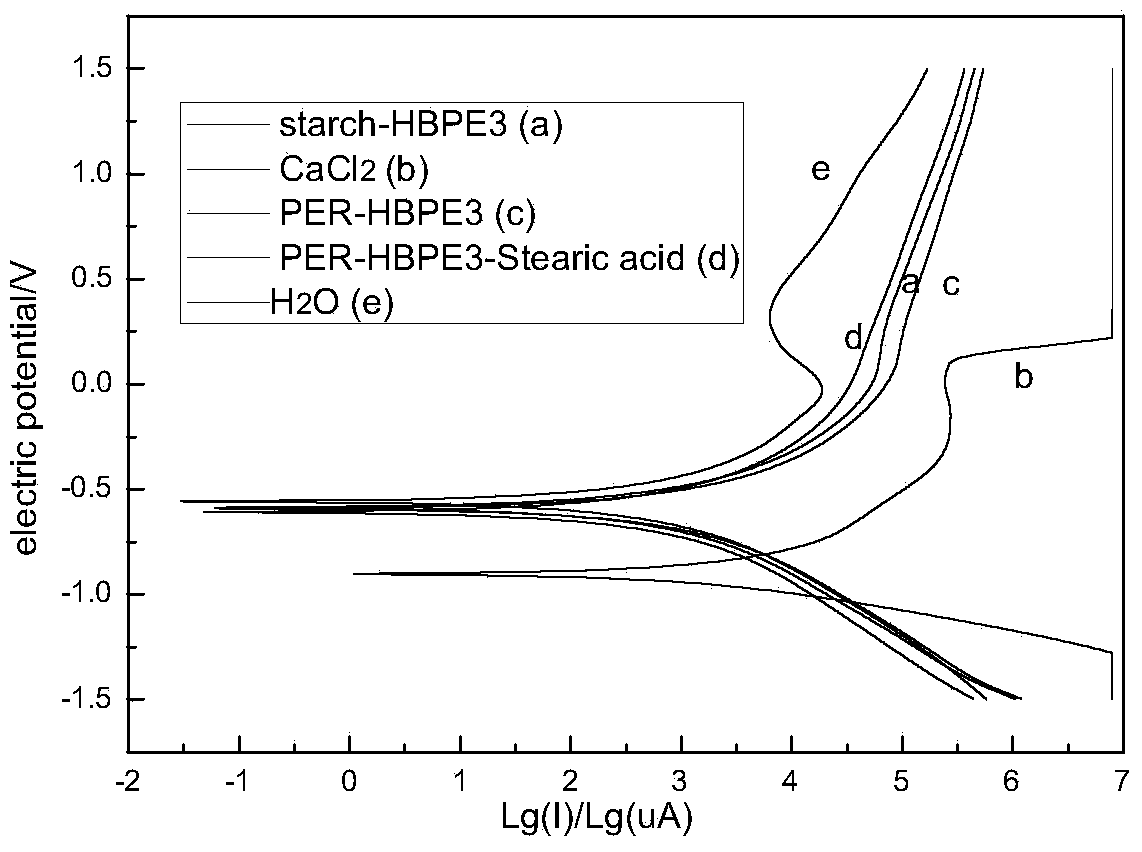

Image

Examples

Embodiment 1

[0035] a monomer N, the preparation of N-dihydroxyethyl-3-aminopropionic acid methyl ester

[0036] Take 1 mole part of methanol and add it into the reactor, slowly add 1 mole part of diethanolamine (DEA) under stirring, continue stirring for 15 minutes, then slowly add 1 mole part of methyl acrylate (MA) dropwise, after the addition is completed, heat up to 40°C and keep it warm for 4 hours , and then evacuated to obtain a colorless transparent oil, namely N, N-dihydroxyethyl-3-aminopropionic acid methyl ester.

[0037] Preparation of b third generation hyperbranched polyester

[0038] Add a certain amount of N,N-dimethylformamide (DMF), 1 mole part of pentaerythritol, and 0.04 mole part of p-toluenesulfonic acid into the reactor, raise the temperature to 140°C, start stirring, and drop 4 mole parts of N , N-dihydroxyethyl-3-aminopropionic acid methyl ester, N 2 After 3 hours of protection reaction, vacuumize for 1 hour. Add 8 molar parts of N, N-dihydroxyethyl-3-amine pro...

Embodiment 2

[0044] a monomer N, the preparation of N-dihydroxyethyl-3-aminopropionic acid methyl ester

[0045] Take 1 mole part of methanol and add it to the reactor, slowly add 1 mole part of diethanolamine (DEA) under stirring, continue stirring for 15 minutes, then slowly add 1.2 mole part of methyl acrylate (MA) dropwise, after the addition, heat up to 30°C and keep it warm for 3 hours , and then evacuated to obtain a colorless transparent oil, namely N, N-dihydroxyethyl-3-aminopropionic acid methyl ester.

[0046] Preparation of b third generation hyperbranched polyester

[0047] Add N,N-dimethylformamide (DMF), 1 mole part of starch, and 0.04 mole part of p-toluenesulfonic acid into the reactor, raise the temperature to 110°C, start stirring, and dropwise add 4 mole parts of N,N- Dihydroxyethyl-3-aminopropionic acid methyl ester, N 2 After protecting the reaction for 1.5h, vacuumize for 1.5h. Add 8 molar parts of N, N-dihydroxyethyl-3-amine propionic acid methyl ester and 0.10 m...

Embodiment 3

[0053] a monomer N, the preparation of N-dihydroxyethyl-3-aminopropionic acid methyl ester

[0054] Take 1 mole part of methanol and add it to the reactor, slowly add 1 mole part of diethanolamine (DEA) under stirring, continue stirring for 15 minutes, then slowly add 2.5 mole parts of methyl acrylate (MA) dropwise, after the addition is completed, heat up to 50°C and keep it warm for 2 hours , and then evacuated to obtain a colorless transparent oil, namely N, N-dihydroxyethyl-3-aminopropionic acid methyl ester.

[0055] Preparation of b third generation hyperbranched polyester

[0056] Add N,N-dimethylformamide (DMF), 1 mole part of pentaerythritol, and 0.04 mole part of p-toluenesulfonic acid into the reactor, raise the temperature to 120°C, start stirring, and dropwise add 3 mole parts of N,N- Dihydroxyethyl-3-aminopropionic acid methyl ester, N 2 After protecting the reaction for 2 hours, vacuumize for 1.5 hours. Additional 6 molar parts of N, N-dihydroxyethyl-3-amine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com