Micro-nano-scale speckle manufacturing method

A manufacturing method and micro-nano-scale technology, which are applied in the photoengraving process, instruments, optics and other directions of the pattern surface, can solve the problems of small manufacturing area, complex technical problems and high cost, and achieve high size and density accuracy and simple process. Flexible, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

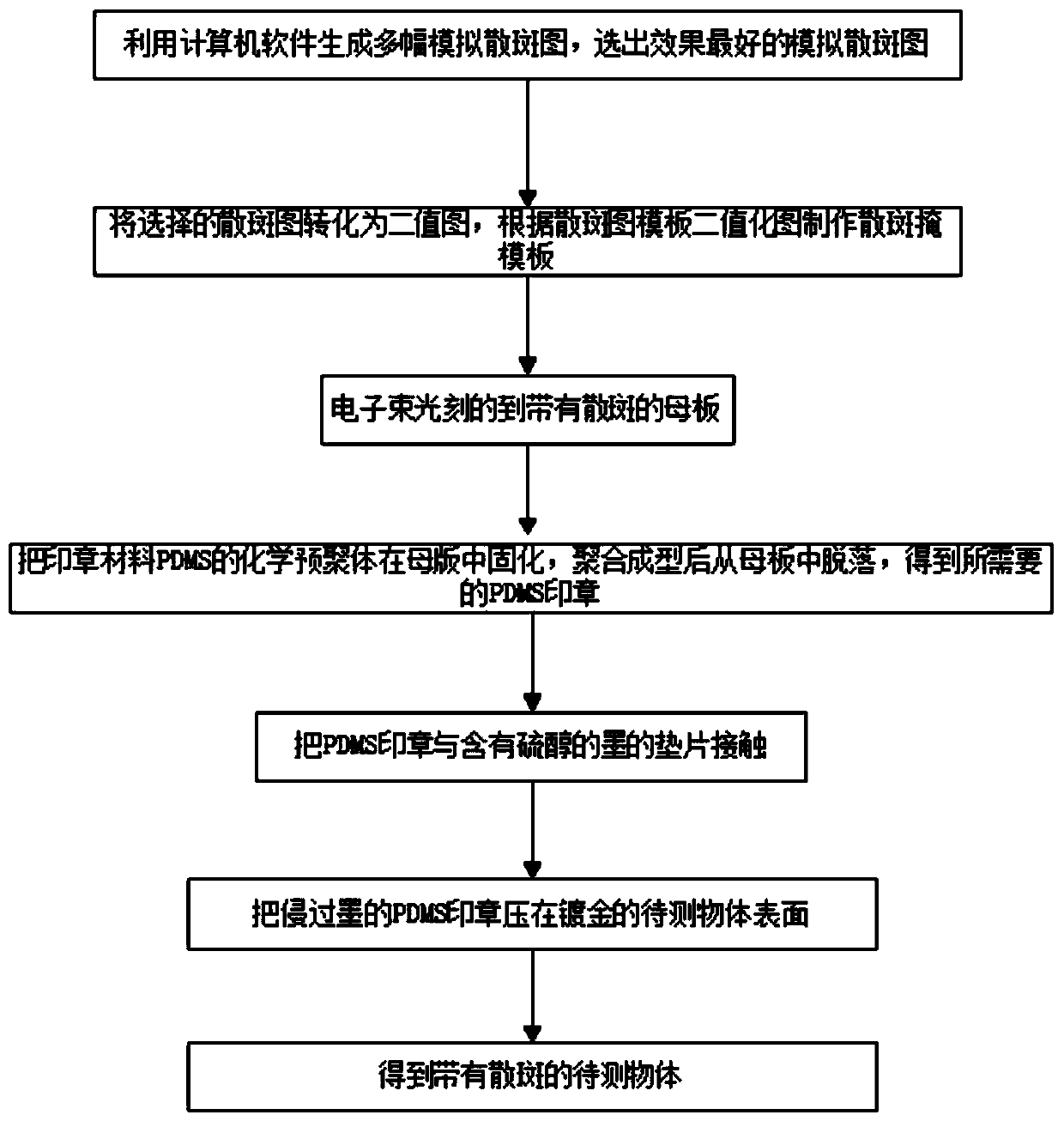

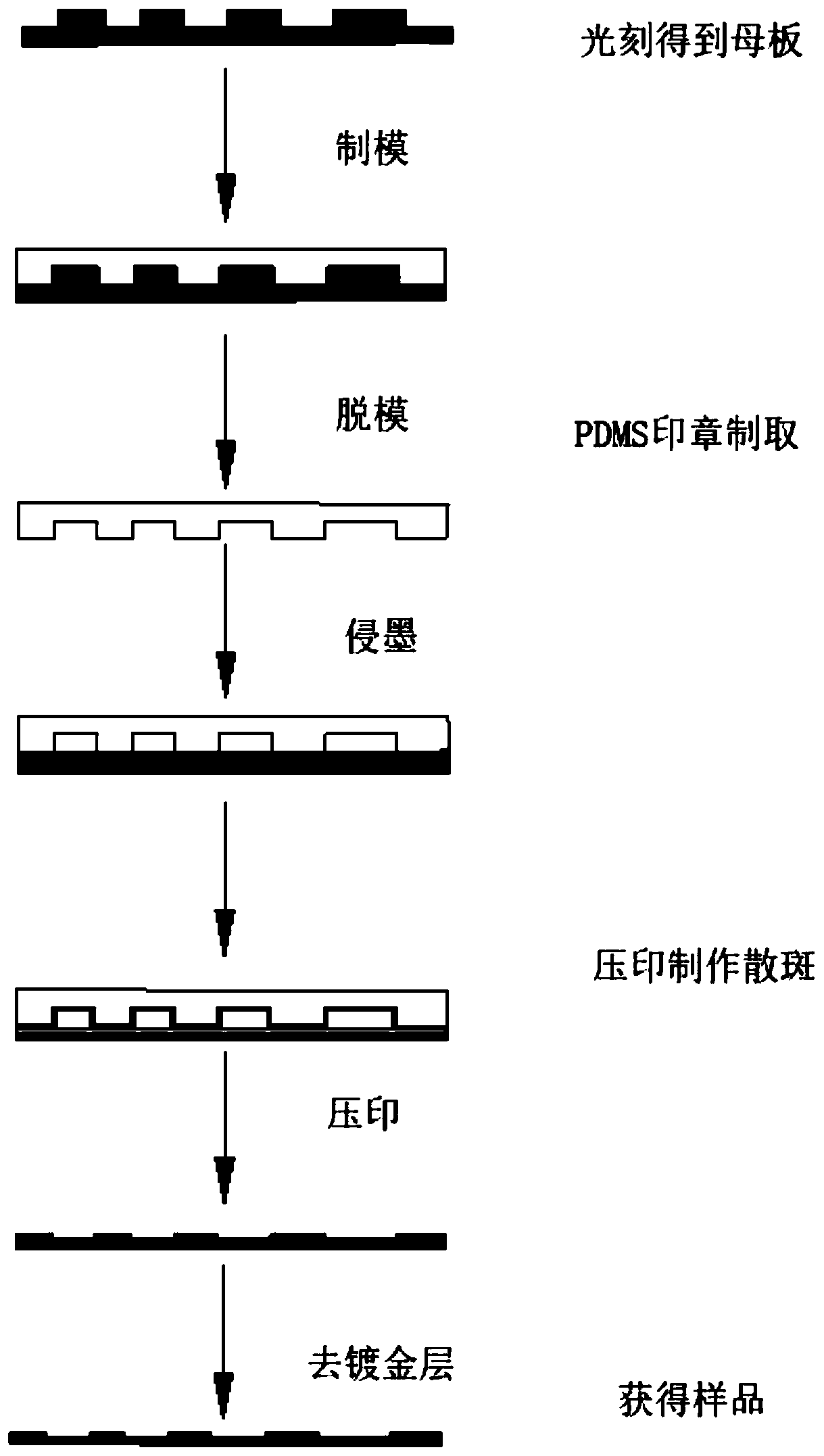

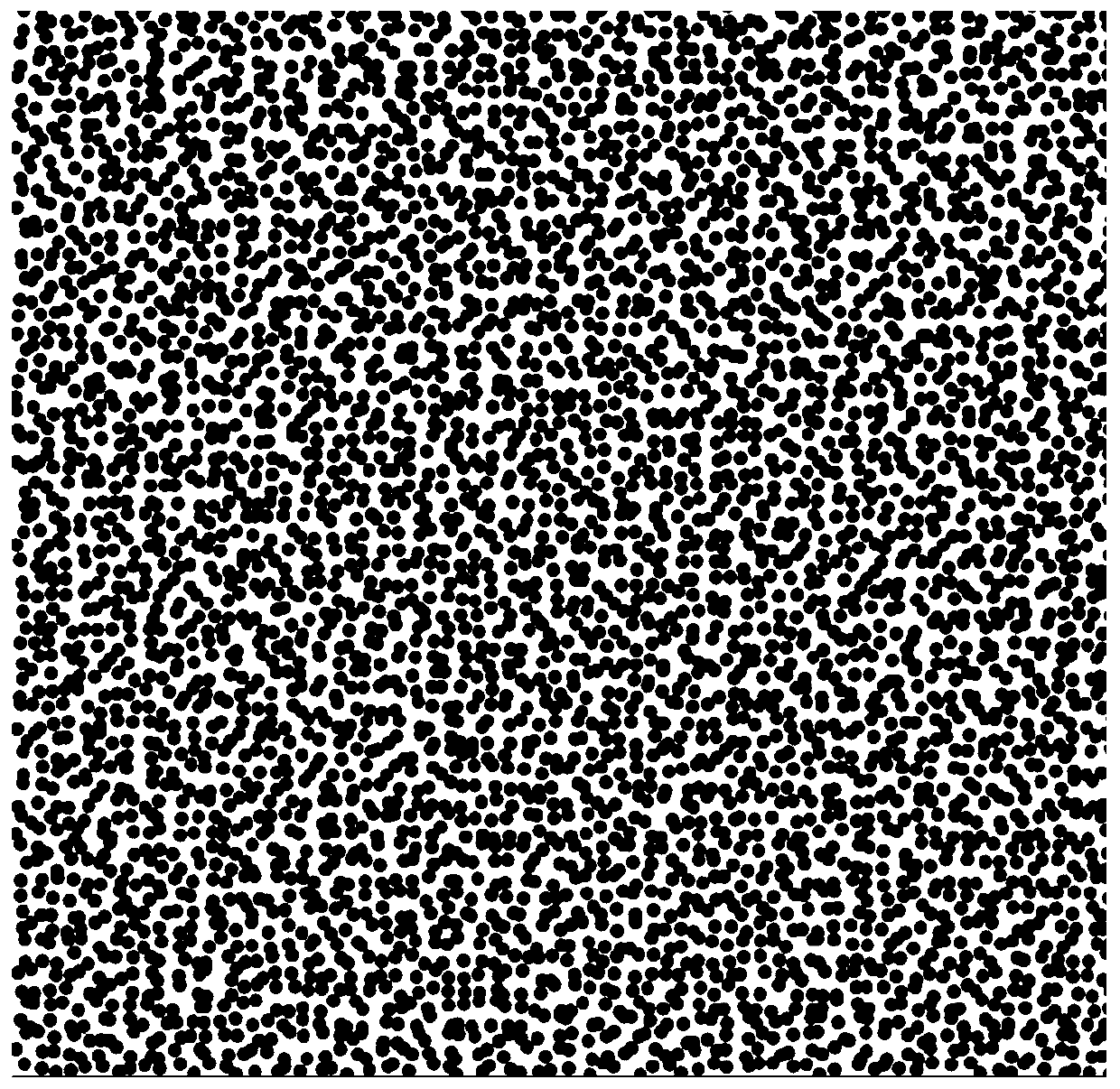

[0024] Using computer software to generate multiple simulated speckle images with different speckle sizes and numbers, the Gaussian algorithm is used in this embodiment, and the gray levels of each speckle can be expressed by the following function:

[0025]

[0026] Among them, s is the number of speckle particles; R is the size of speckle particles; two-dimensional random variable (x k ,y k ) is the center position of the kth speckle particle; I K is the gray value of the center of the kth speckle particle.

[0027] Select the best simulation image according to the average gray gradient sum of the image, and convert the speckle image into a binary image, where the average gray gradient square sum of the image can be expressed by the following function:

[0028]

[0029] M and N are the height and width of the image respectively, in pixels, is the modulus of the gray gradient vector of each pixel. A laser printer will be used to print the binary speckle pattern ont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com