Alkali-free accelerating agent and preparation method and application thereof

A technology of quick-setting agent and formula, which is applied in the field of civil engineering and construction materials, can solve the problems of large quantities and storage stability that need to be further improved, and achieve the effects of reducing rebound, fast setting rate, and increasing cohesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

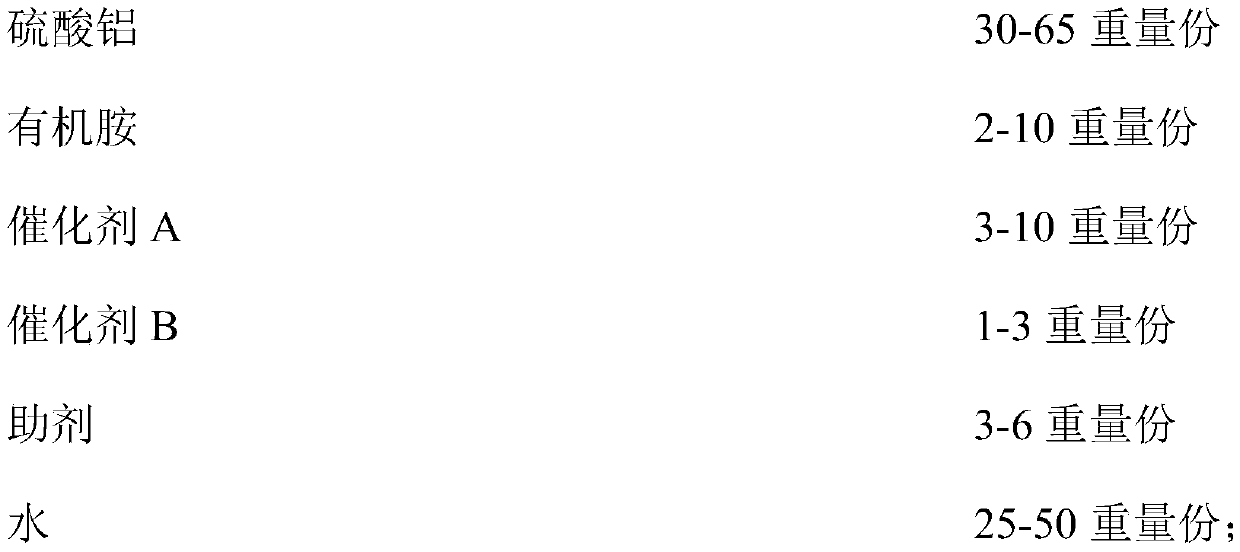

[0069] This embodiment provides a non-alkali quick-setting agent, which includes the following components in parts by weight:

[0070]

[0071] The preparation method of described alkali-free quick-setting agent is as follows:

[0072] (1) Dissolve the aluminum sulfate, organic amine and catalyst A in the formula amount in water at 80°C, and stir at 70rpm for 100min to obtain the stock solution of alkali-free quick-setting agent;

[0073] (2) Add the catalyst B of the recipe amount into the stock solution of the alkali-free quick-setting agent, stir for 20 minutes, add the synergist of the recipe amount, stir for 20 minutes, add the stabilizer of the recipe amount, stir for 15 minutes, and obtain the alkali-free accelerator.

Embodiment 2

[0075] The difference from Example 1 is that aluminum dihydrogen phosphate is 6 parts by weight, and citric acid is 3 parts by weight.

Embodiment 3

[0077] The difference from Example 1 is that aluminum dihydrogen phosphate is 8 parts by weight, and citric acid is 1 part by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial setting time | aaaaa | aaaaa |

| Final setting time | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com