A kind of method of simple superhydrophobic modification melamine sponge

A technology of superhydrophobic modification and melamine sponge, which is applied in the modification of superhydrophobic-superoleophilic melamine sponge, superhydrophobic sponge and its preparation field, which can solve the problems of complex and expensive equipment, poor stability of modified materials, and limitations Industrial application and other issues, to achieve the effect of excellent recycling performance, low price, good adsorption capacity and selective separation ability of oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take a cut melamine sponge and completely immerse it in the prepared dilute nitric acid solution with a concentration of 0.5mol / L. After soaking for 60 minutes, the sponge was taken out and squeezed dry. After washing the surface of the sponge with water, and drying it in an oven at 60 °C, a superhydrophobic-superoleophilic modified melamine sponge can be obtained.

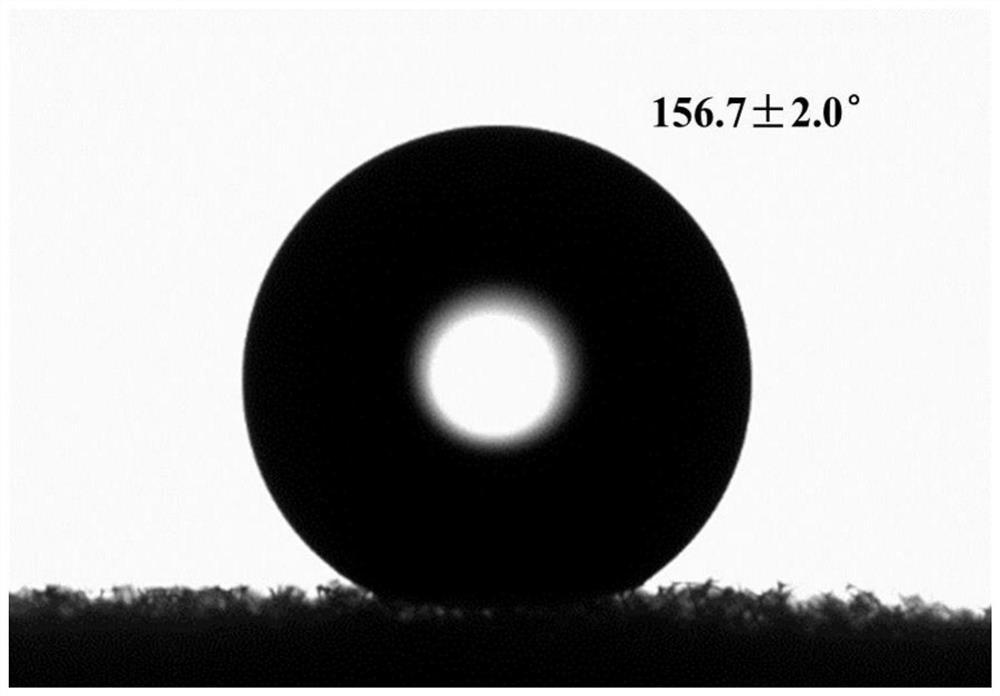

[0024] The superhydrophobic modified melamine sponge prepared according to Example 1 was tested by a contact angle meter ( figure 1 ), the average hydrophobic angle is 156.7±2.0°, which shows that the sponge has excellent hydrophobicity.

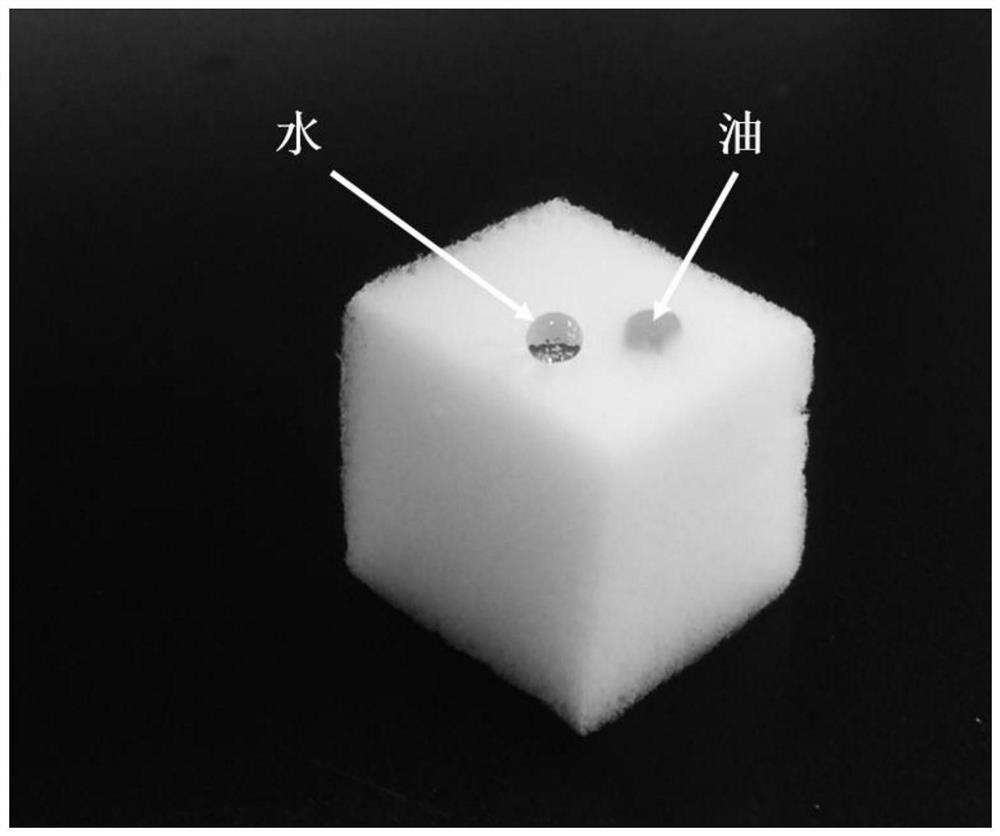

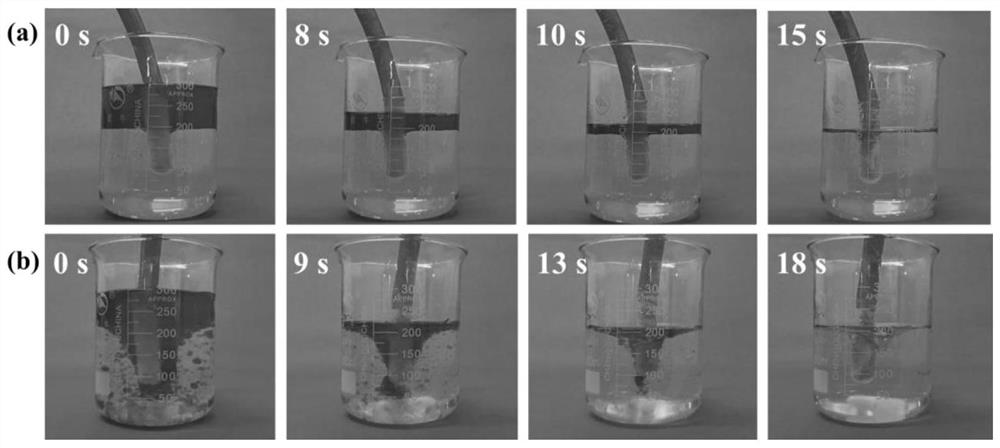

[0025] Schematic diagram of the hydrophobic and lipophilic properties of the superhydrophobic modified melamine sponge prepared according to Example 1 ( figure 2 ), the water droplets form a spherical shape and stand stably on the surface of the sponge, while the oil droplets have quickly penetrated into the sponge, which shows the excellent superhydrophobicity-superol...

Embodiment 2

[0027] The cut commercial melamine sponge was completely immersed in the prepared dilute nitric acid solution with a concentration of 0.75 mol / L. The sponge was taken out after soaking for 30 minutes and squeezed dry. The sponge was washed several times with water to remove excess nitric acid, and then dried in an oven at 60 °C to obtain a superhydrophobic melamine sponge. The microscopic morphology of the sponge before modification, such as Figure 4 (a,b); the modified microstructures, such as Figure 4 (c, d).

[0028] To sum up, the present invention discloses a simple method for superhydrophobic modification of melamine sponge. The process of super-hydrophobic modified sponge by dilute nitric acid of the present invention has high efficiency, does not need complicated instruments and equipment, and is easy to prepare on a large scale. The nitric acid used in the modification has the characteristics of wide source and low price, and the obtained sponge is non-toxic and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com