A kind of hydrogel surface patterning material and preparation method and application thereof

A surface patterning and hydrogel technology, which is applied in the field of hydrogel surface patterning materials and its preparation, can solve the problems of large pattern randomness, difficult control of hydrogel swelling performance and osmotic pressure, and accuracy defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a hydrogel surface patterned material, comprising the following steps:

[0029] (1) provide hydrogel ink, said hydrogel ink comprises polyethylene glycol diacrylate, methacrylate-β-hydroxyethyl ester, methacrylate-3-sulfonic acid propyl ester potassium salt, aliphatic Polyurethanes, photoinitiators and dyes;

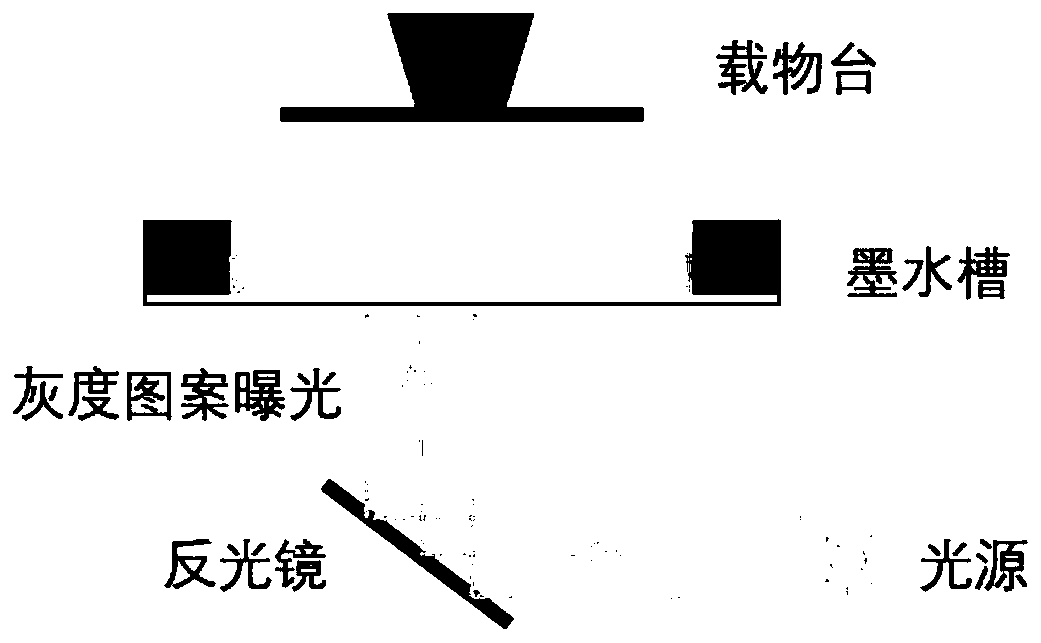

[0030] (2) Printing the hydrogel ink in the step (1) by using the gray-scale recognition light-curing printing technology to obtain the first product of hydrogel printing;

[0031] (3) Soak the hydrogel printing primary product obtained in the step (2) in water, and swell to obtain a hydrogel surface patterned material.

[0032] The present invention provides hydrogel ink, and described hydrogel ink comprises polyethylene glycol diacrylate, methacrylic acid-beta-hydroxyethyl ester, methacrylic acid-3-sulfonic acid propyl ester potassium salt, aliphatic polyurethane , photoinitiators and dyes.

[0033] In parts by ma...

Embodiment 1

[0062] In parts by mass, according to 75 parts of PEGDA, 15 parts of HEMA, 5 parts of SPMA and 5 parts 8413, 0.3 parts of Irgacure819 photoinitiator 0.03 parts of Orasol dye (Orasoldye) to prepare raw materials;

[0063] The raw materials are mixed under the condition of mechanical stirring and synchronous heating, and then the dissolved oxygen in the mixed material is removed by centrifugation to obtain a uniform, clear and transparent hydrogel photocurable ink, which is ready for use; when mixing, the stirring speed is 400r / min, and the heating temperature at 50°C for 2 hours;

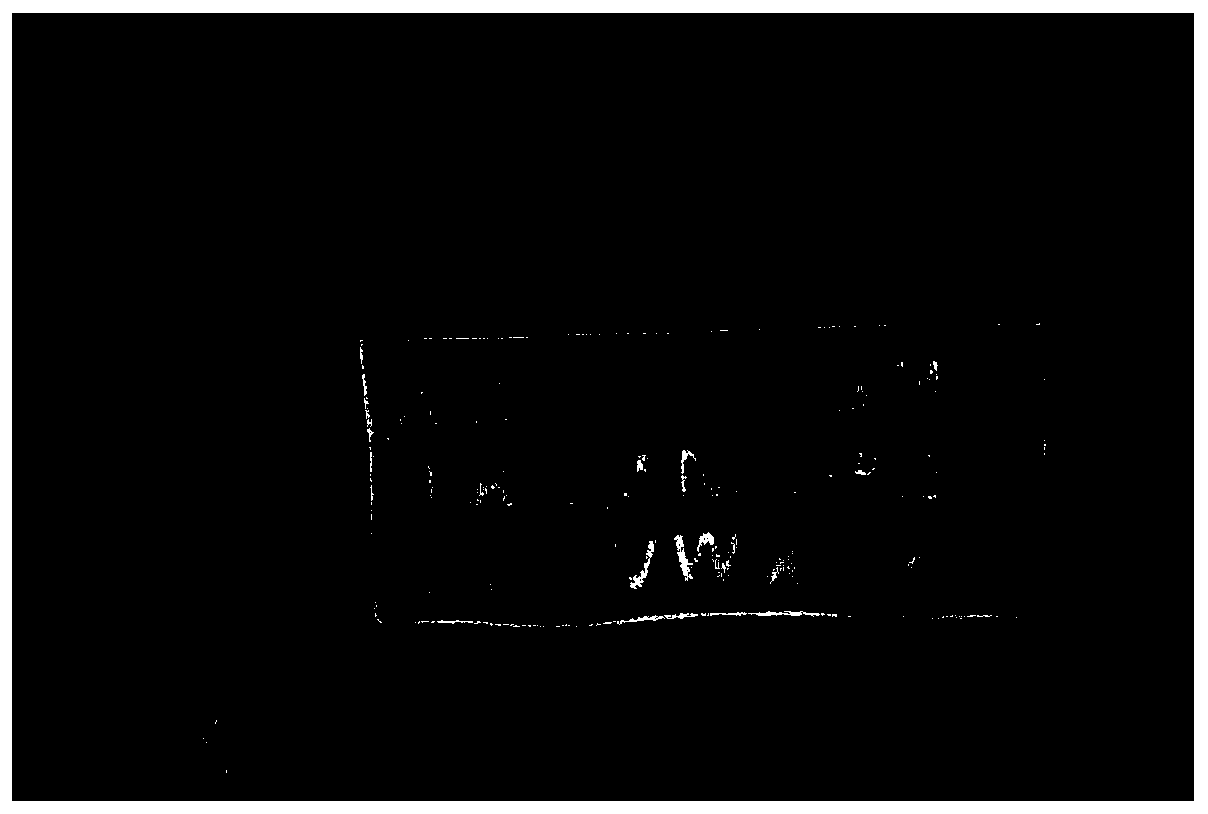

[0064] according to figure 1 The method shown is to use a commercial DLP printer (digital surface exposure printer) to print. When printing, design the print pattern through Photoshop; set the exposure time to 30s, the grayscale exposure to 30%, and the exposure pattern to the English alphabet. Print on the stage to prepare two-dimensional hydrogel films.

[0065] Soak the printed primary product...

Embodiment 2

[0067] Test according to the method of Example 1, the difference is that the amount of each component of the hydrogel ink is different, listed in Table 1; the exposure pattern is designed as a printed circuit board, the exposure time is set to 30s, and the grayscale exposure is 45%, to obtain image 3 Patterned material shown. Depend on image 3 It can be seen that this embodiment can also obtain a hydrogel material with a clear surface patterning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com