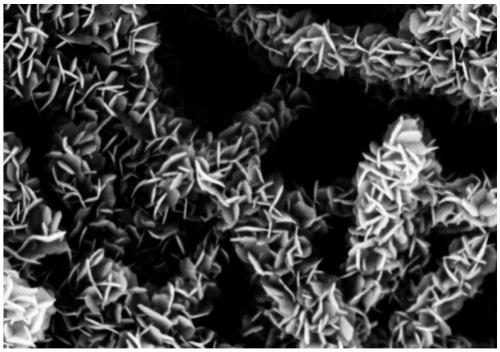

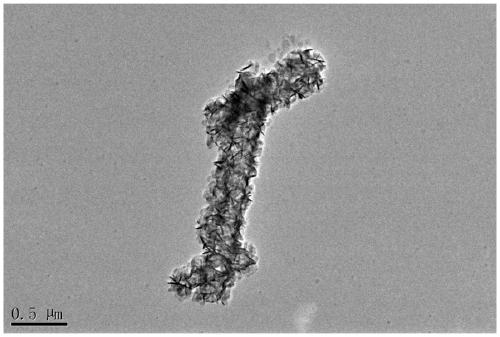

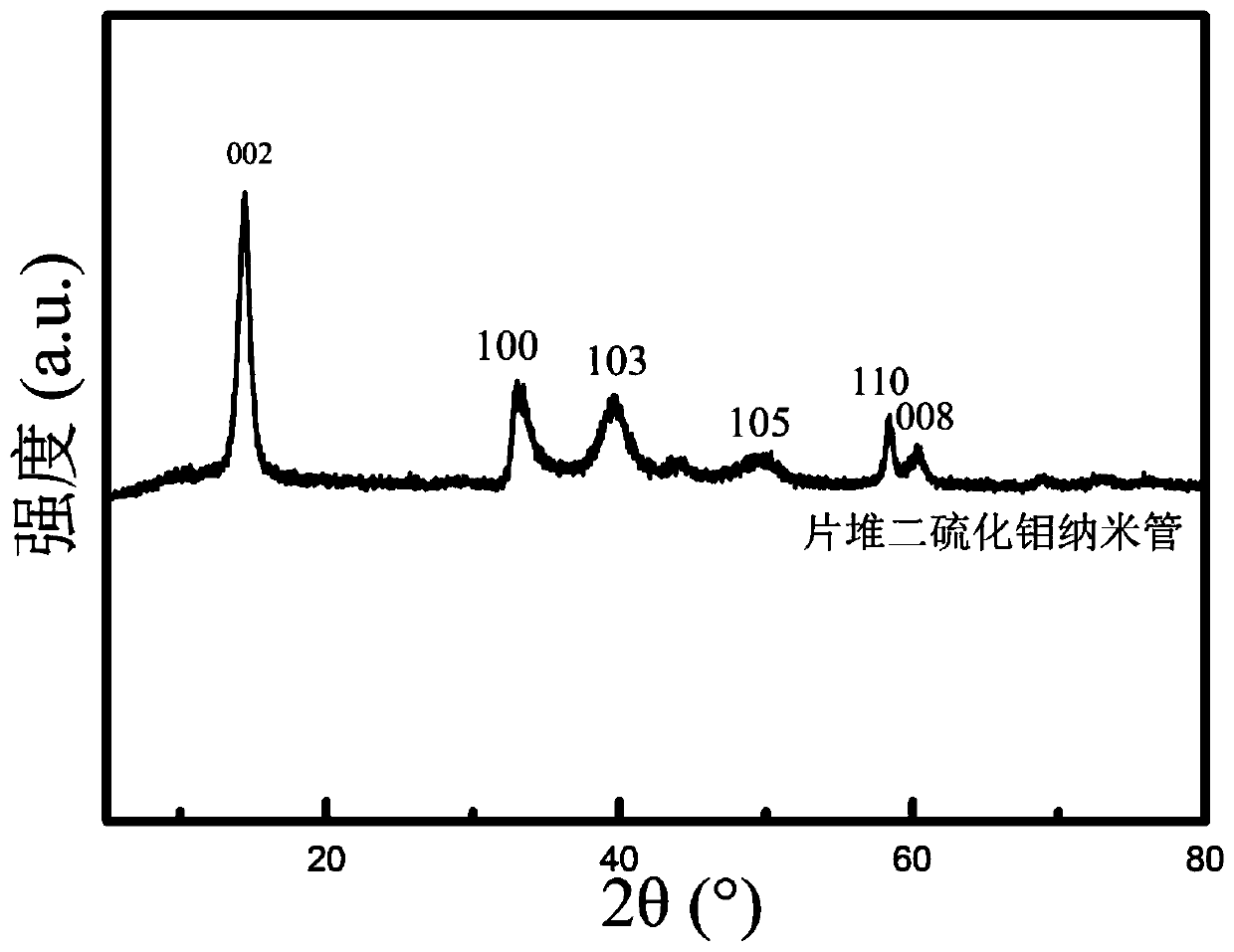

A kind of preparation method of sheet-stacked molybdenum disulfide nanotubes

A molybdenum disulfide and nanotube technology, which is applied in the field of transition metal compound material preparation, can solve the problems of large volume expansion, poor electrical conductivity, and limit the practical application of molybdenum disulfide materials, and achieves the effect of simple method and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 1.21g sodium molybdate and 0.6g sodium chloride to 60mL deionized water to obtain a solution, continue stirring for 10min to obtain a uniform dispersion, add 3mol / L hydrochloric acid solution to adjust the pH value to 1, and transfer to a hydrothermal kettle The hydrothermal reaction was carried out in an oven, the reaction temperature was 180°C, and the reaction time was 24 hours. After the reaction kettle was cooled to room temperature, the obtained dispersion was subjected to suction filtration to separate the light blue precipitate, and the obtained solid was washed with deionized water. , dried in an oven at 60° C. for 24 hours to obtain molybdenum oxide nanobelts.

[0025] (2) Weigh 20 mg of molybdenum oxide nanobelts and 100 mg of sulfur powder in step (1), grind them in agate, mix them evenly, and add them to a porcelain ark with a length of 6 cm and a width of 3 cm. The tube furnace is vulcanized at high temperature, the protective gas is nitrogen, the ...

Embodiment 2

[0030] (1) Add 1.21g sodium molybdate and 1.21g sodium chloride to 40mL deionized water to obtain a solution, continue stirring for 10min to obtain a uniform dispersion, add 3mol / L hydrochloric acid solution to adjust the pH value to 1.5, and transfer to a hydrothermal kettle The hydrothermal reaction was carried out in an oven, the reaction temperature was 190°C, and the reaction time was 20h. After the reaction kettle was cooled to room temperature, the obtained dispersion liquid was subjected to suction filtration to separate the light blue precipitate, and the obtained solid was washed with deionized water. , dried in an oven at 60° C. for 24 hours to obtain molybdenum oxide nanobelts.

[0031] (2) Weigh 20 mg of molybdenum oxide nanobelts and 80 mg of sulfur powder in step (1), grind them in agate, mix them evenly, and add them to a porcelain ark with a length of 6 cm and a width of 3 cm. The tube furnace is vulcanized at high temperature, the protective gas is argon, the...

Embodiment 3

[0033] (1) Add 0.6g sodium molybdate and 1.2g sodium chloride to 12mL deionized water to obtain a solution, continue stirring for 10min to obtain a uniform dispersion, add 3mol / L hydrochloric acid solution to adjust the pH value to 0.5, and transfer to a hydrothermal kettle The hydrothermal reaction was carried out in an oven, the reaction temperature was 200°C, and the reaction time was 18 hours. After the reaction kettle was cooled to room temperature, the obtained dispersion was subjected to suction filtration to separate the light blue precipitate, and the obtained solid was washed with deionized water. , dried in an oven at 60° C. for 24 hours to obtain molybdenum oxide nanobelts.

[0034] (2) Weigh 20 mg of molybdenum oxide nanobelts and 100 mg of sulfur powder in step (1), grind them in agate, mix them evenly, and add them to a porcelain ark with a length of 6 cm and a width of 3 cm. The tube furnace is vulcanized at high temperature, the protective gas is nitrogen, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com