A kind of pellet iron-based composite binder and its preparation and use method

A technology for pellets and binders, applied in the field of sintered pellet preparation, can solve the problems of poor preheating and roasting pellet strength, lack of detailed description, low burst temperature, etc., achieves good mixing and binding effect, and reduces processing costs , the effect of efficient recycling of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

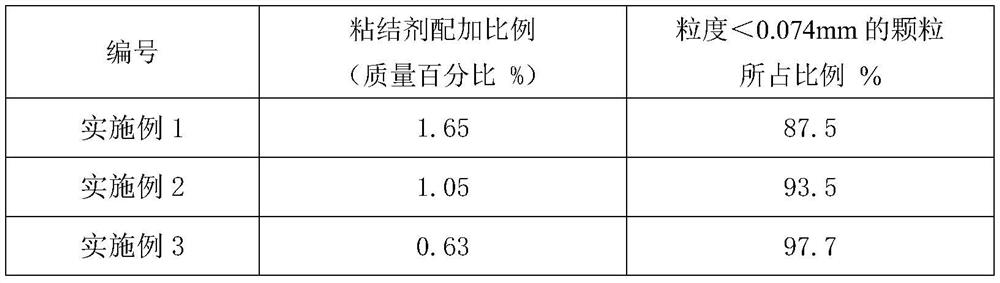

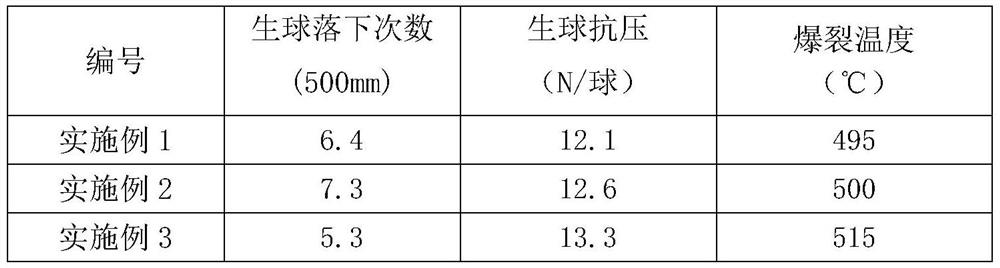

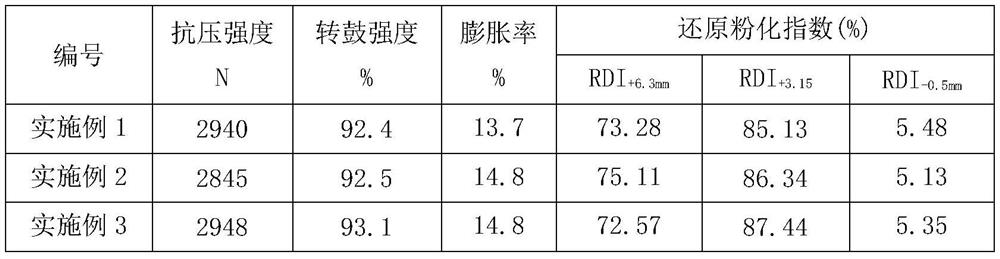

Examples

preparation example Construction

[0022] A preparation method of a pellet iron-based composite binder, comprising the following steps:

[0023] 1) Put the weighed converter OG mud into the reaction vessel according to the dry basis ratio;

[0024] 2) The hydroxypropyl methylcellulose solution obtained after the etherification reaction of hydroxypropyl methylcellulose is directly added to the reaction vessel equipped with converter OG mud according to the dry basis ratio;

[0025] 3) Add the instant sodium carboxymethylcellulose solution into the reaction vessel equipped with converter OG mud according to the dry basis ratio;

[0026] 4) The reaction vessel is placed in a microwave generator, and the heap leaching reaction is radiated and heated for 10 to 20 minutes; the heating temperature is 100 to 110° C., and the dried product is ground and sieved to obtain the iron-based pellets. Binder, the particle size of the finished product is composed of particles less than 0.044mm accounting for more than 95%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com