Pellet ore magnesium-based composite binder as well as preparation method and application method thereof

A technology of pellets and binders, applied in the field of sintered pellet preparation, to achieve the effects of improving the metallurgical properties of pellets, relieving pressure, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

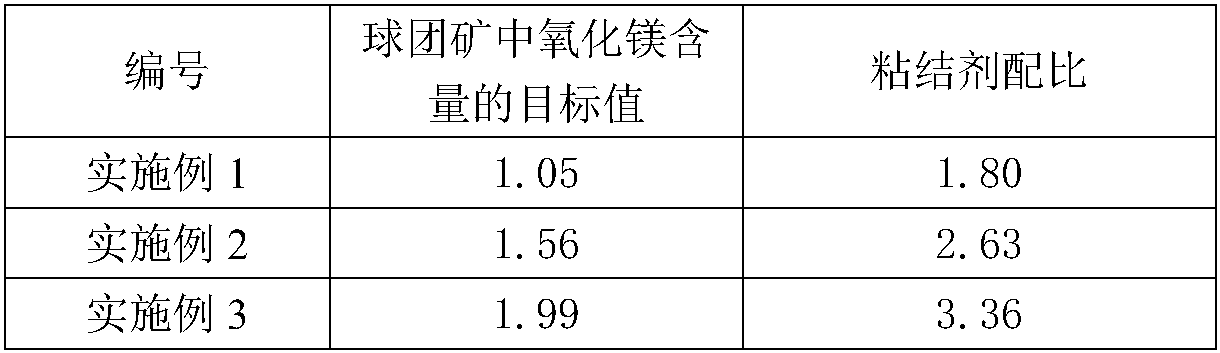

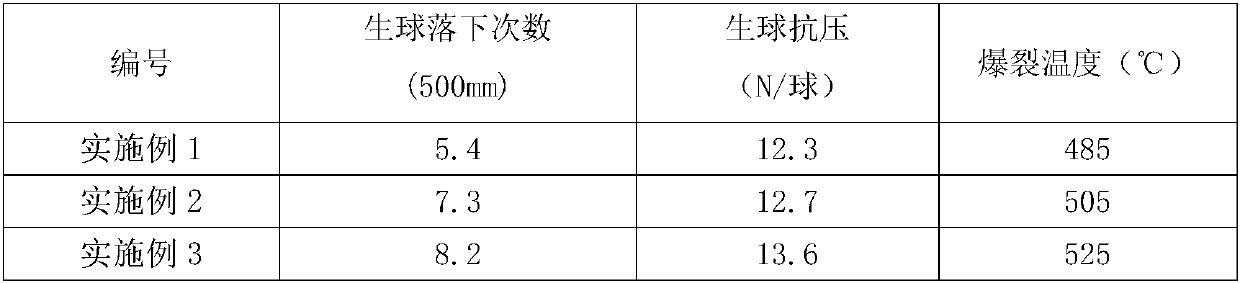

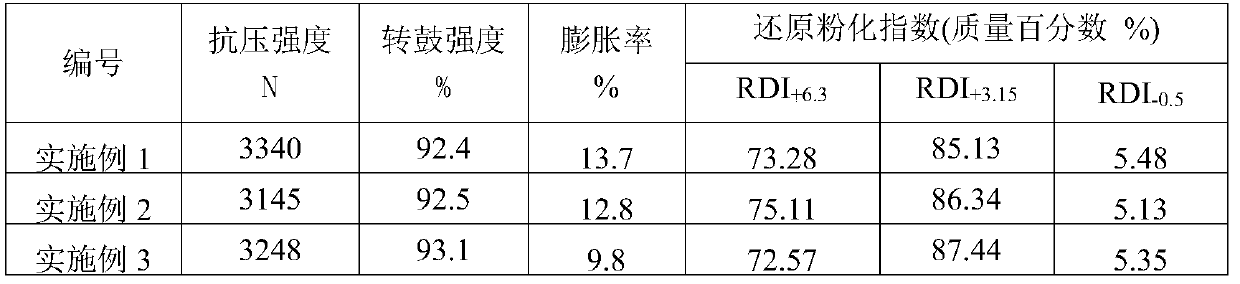

Examples

preparation example Construction

[0026] A preparation method of pellet magnesium-based composite binder, comprising the following steps:

[0027] 1) The magnesite tailings are roasted at medium temperature to obtain a composite of magnesium oxide and magnesium carbonate, the composite is crushed and ground into powder, weighed and put into a reaction vessel;

[0028] 2) The hydroxypropyl methylcellulose solution obtained after the etherification reaction of hydroxypropyl methylcellulose is directly added to the reaction vessel equipped with magnesium oxide and magnesium carbonate complex according to the dry basis ratio;

[0029] 3) The instant sodium carboxymethylcellulose solution is added to the reaction vessel equipped with magnesium oxide and magnesium carbonate complex according to the proportion on a dry basis;

[0030] 4) Place the reaction vessel in a microwave generator, and radiate and heat the heap leaching reaction for 10-20 minutes; after heating, the temperature is 100-110°C, and the dried prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com