a co 2 A method of synergistic gasification of sludge with sub/supercritical water

A technology of supercritical water and synergistic effect, applied in the field of resources and environment, can solve the problems of low pyrolysis gasification rate, lower gasification gas calorific value, and lower gasification gas calorific value, so as to improve gasification efficiency, Efficient recovery and yield improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be further described in detail below.

[0035] a CO 2 A method for synergistically gasifying sludge with sub / supercritical water, comprising the following steps:

[0036] Step S1, put the remaining sludge produced by the urban sewage plant into the reaction kettle, and purge it with carbon dioxide for 5 minutes to remove impurity gases; then pass it into a carbon dioxide environment of 0-8MPa and keep the pressure for 5-15 minutes;

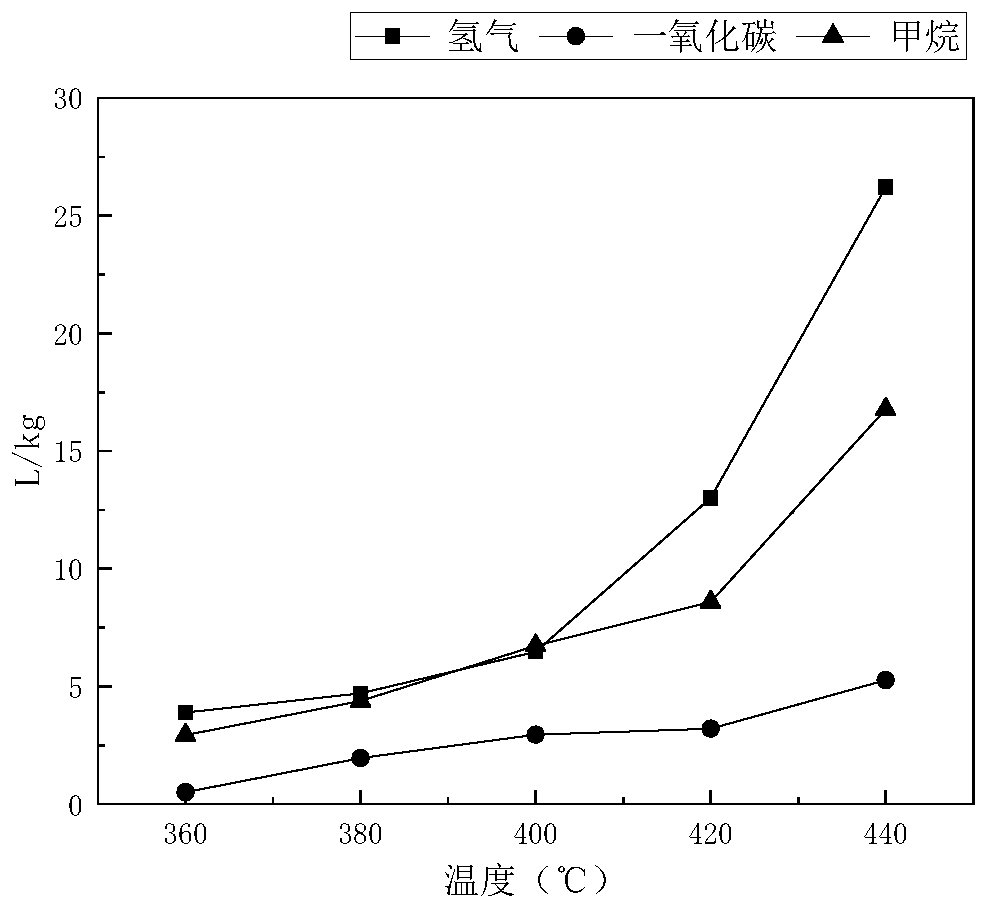

[0037] Step S2, heating the reactor until the target temperature is 350°C-460°C, the pressure reaches 8MPa-26MPa, and the sludge is gasified in the carbon dioxide-supercritical water system.

[0038] In step S2, CO in the reaction device 2 The ratio of the amount of substance to water is 1:3-20.

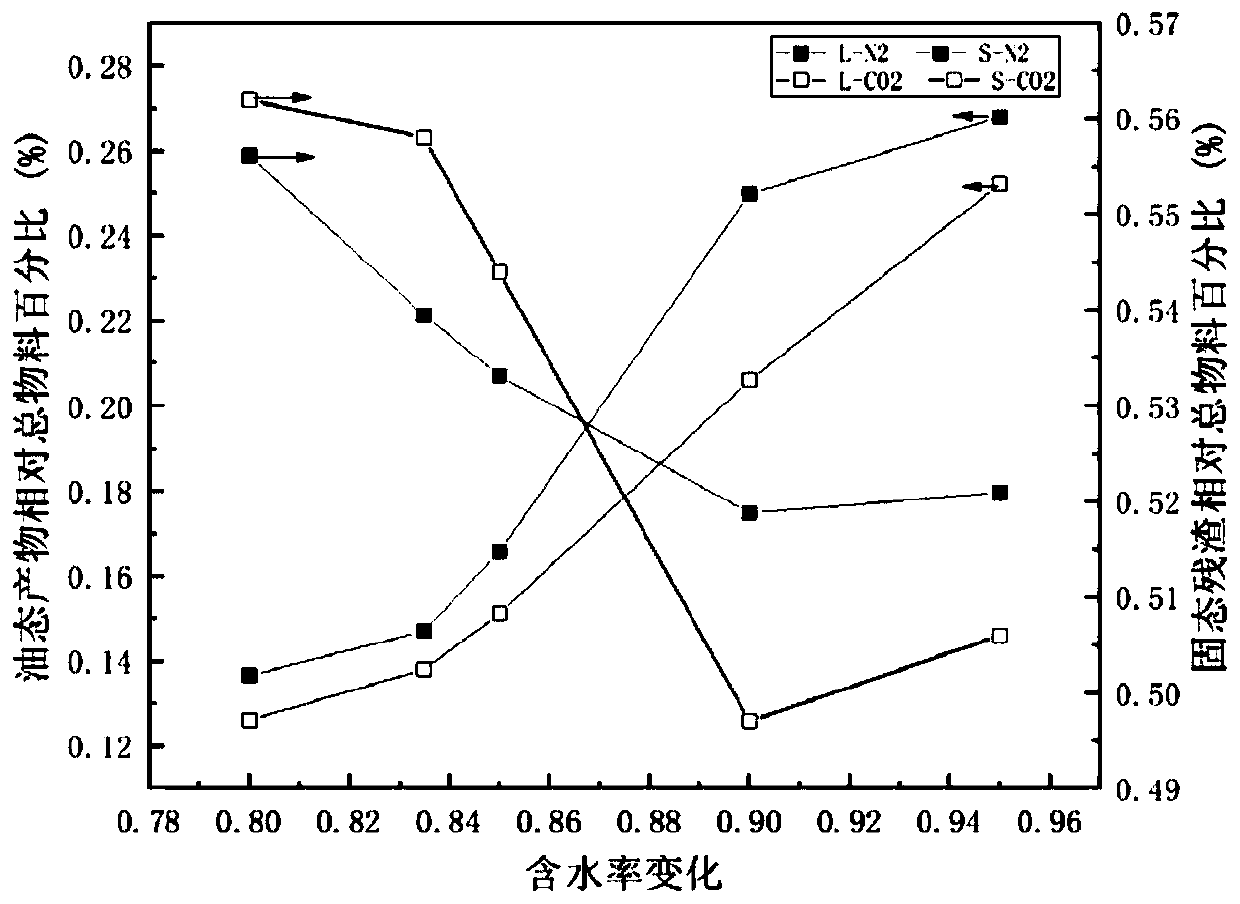

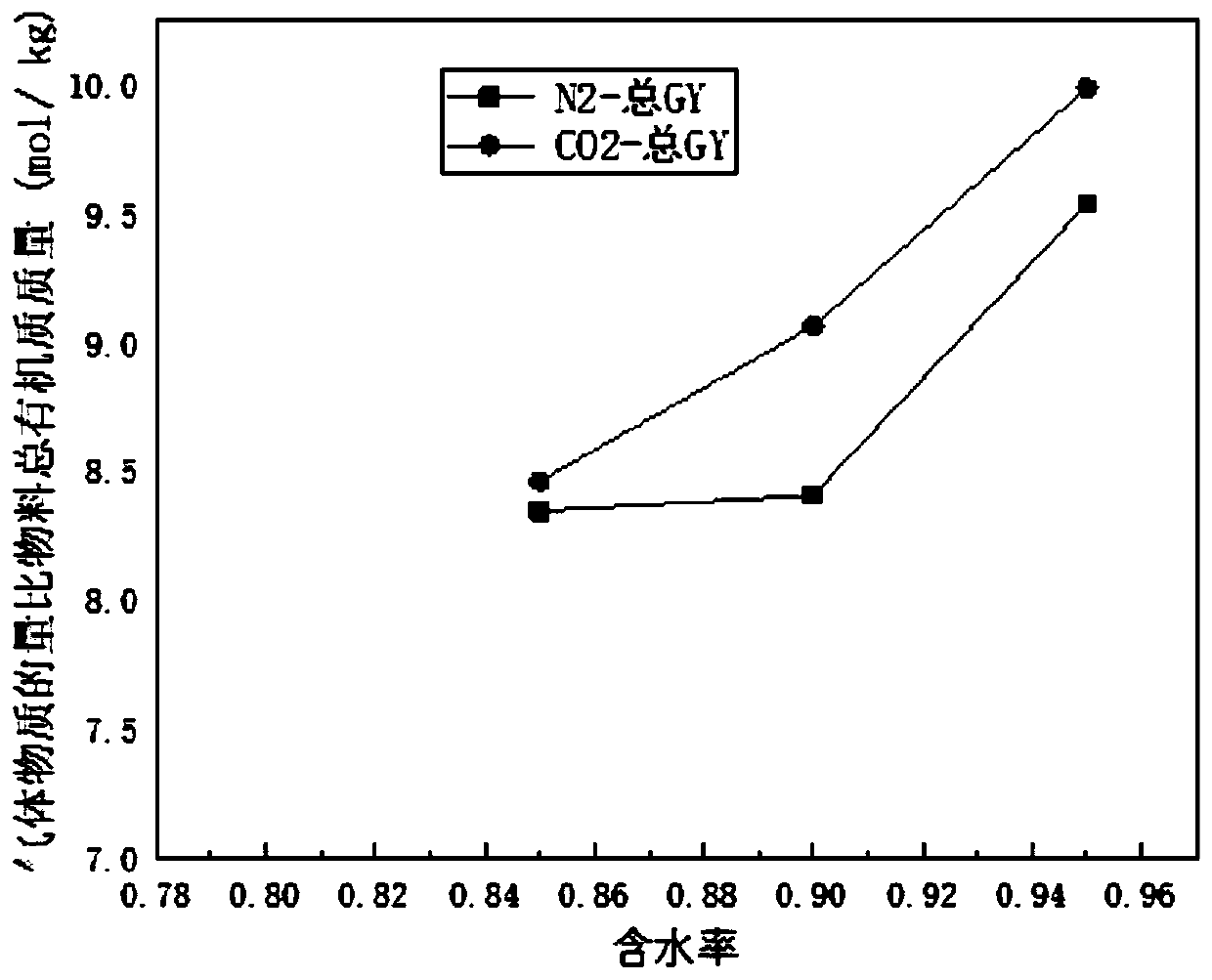

[0039] Sludge with different water content was used for CO 2 Co-processing with sub / supercritical water and using N 2 Replace CO 2 Corresponding experiments were carried out to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com