Manufacturing method of high-tensile lithium battery copper foil

A manufacturing method and a technology for tensile lithium, applied in electroforming, electrolysis process, etc., can solve the problem of unstable manufacturing process, achieve the effects of stable and easy-to-control brightness, increase density, and reduce crystal growth defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add the elemental copper metal into the copper-dissolving tank containing sulfuric acid, blow in high-temperature air with a screw fan, and dissolve the copper to prepare the main electrolyte of acidic copper sulfate. The main electrolyte is filtered in multiple stages and mixed with the additive solution to obtain the electrolyte. In the liquid, the copper ion concentration is 50 g / L, the acid content is 80 g / L, the chloride ion concentration is 30 mg / L, and the composition of other additives is:

[0023] Sodium polydisulfide dipropane sulfonate: 1 mg / L;

[0024] Mercaptobenzimidazole: 2 mg / L;

[0025] Collagen (number average molecular weight 3000-5000): 3 mg / L;

[0026] Polyethyleneimine (average molecular weight 1200): 2 mg / L

[0027] Thiourea: 5 mg / L;

[0028] The above electrolytic solution is heat-exchanged to 30 o C, into the electrolyzer. The cathode of the electrolytic cell is a seamless drum type titanium roller, and the anode is a size-limited anode. a...

Embodiment 2

[0030] Add the elemental copper metal into the copper-dissolving tank containing sulfuric acid, blow in high-temperature air with a screw fan, and dissolve the copper to prepare the main electrolyte of acidic copper sulfate. The main electrolyte is filtered in multiple stages and mixed with the additive solution to obtain the electrolyte. In the liquid, the copper ion concentration is 100 g / L, the acid content is 140 g / L, the chloride ion concentration is 100 mg / L, and the composition of other additives is:

[0031] Sodium mercaptan propane sulfonate: 20 mg / L;

[0032] Sodium 3-mercapto-1-propanesulfonate: 50 mg / L;

[0033] Collagen (number average molecular weight 3000-5000): 30 mg / L;

[0034] Polyether ammonia (average molecular weight 4000): 50 mg / L

[0035] Ethylenethiourea: 70 mg / L;

[0036] The above electrolytic solution is heat exchanged to 70 o C, into the electrolyzer. The cathode of the electrolytic cell is a seamless drum type titanium roller, and the anode is...

Embodiment 3

[0038] Add the elemental copper metal into the copper-dissolving tank containing sulfuric acid, blow in high-temperature air with a screw fan, and dissolve the copper to prepare the main electrolyte of acidic copper sulfate. The main electrolyte is filtered in multiple stages and mixed with the additive solution to obtain the electrolyte. In the liquid, the copper ion concentration is 85 g / L, the acid content is 100 g / L, the chloride ion concentration is 30 mg / L, and the composition of other additives is:

[0039] Sodium polydisulfide dipropane sulfonate: 20 mg / L;

[0040] Sodium 3-mercapto-1-propanesulfonate: 3 mg / L;

[0041] Polyether ammonia (number average molecular weight 4000): 25 mg / L;

[0042] Polyethyleneimine (average molecular weight 1200): 12 mg / L

[0043] Diethylthiourea: 15 mg / L;

[0044] The above electrolytic solution is heat exchanged to 55 o C, into the electrolyzer. The cathode of the electrolytic cell is a seamless drum type titanium roller, and the an...

PUM

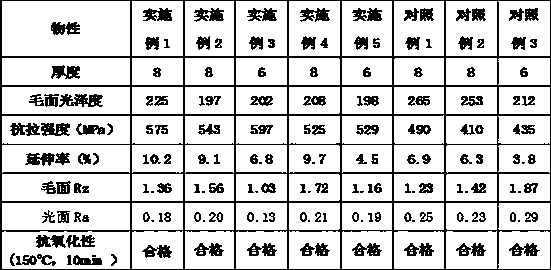

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com