Underwater siphon material and preparation method and application thereof

A siphon tube and ammonia water technology, applied in textiles and papermaking, liquid-repelling fibers, animal fibers, etc., can solve problems such as difficult repairs, transportation defects, and high costs, and achieve good affinity, cheap and easy-to-get reagents, and environmental protection friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with example technical scheme of the present invention is described further:

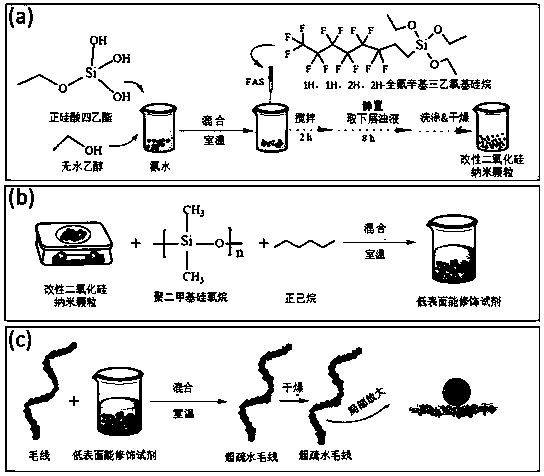

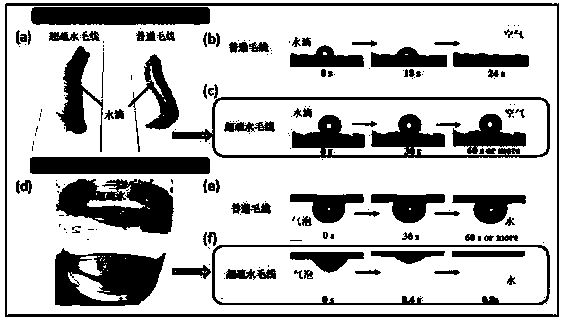

[0035] In the following implementation examples, the general flow chart of the preparation process of superhydrophobic wool is shown in the attached figure 1 . A method for preparing a superhydrophobic wool material involved in a new method of underwater gas transportation, comprising the steps of:

[0036] (1) Modified silica (FAS-SiO 2) Preparation of nanoparticles. Add ammonia water with a concentration of 25%-28%, 98% tetraethyl orthosilicate, and 99.7% absolute ethanol into a 500mL clean beaker in a volume ratio of 70mL:14mL:210mL, and then drop 2.0 μL FAS (1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane), in order to reduce reagent volatilization, seal the upper end of the beaker with a film, and then place it on the 85-2A double digital constant temperature magnetic stirrer , the reaction temperature is controlled at 20°C, the stirring rate is 500r / min, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com