Piezoresistive sensor and preparation method thereof

A sensor, piezoresistive technology, applied in the field of sensors, to achieve the effect of improving sensitivity, improving detection limit, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

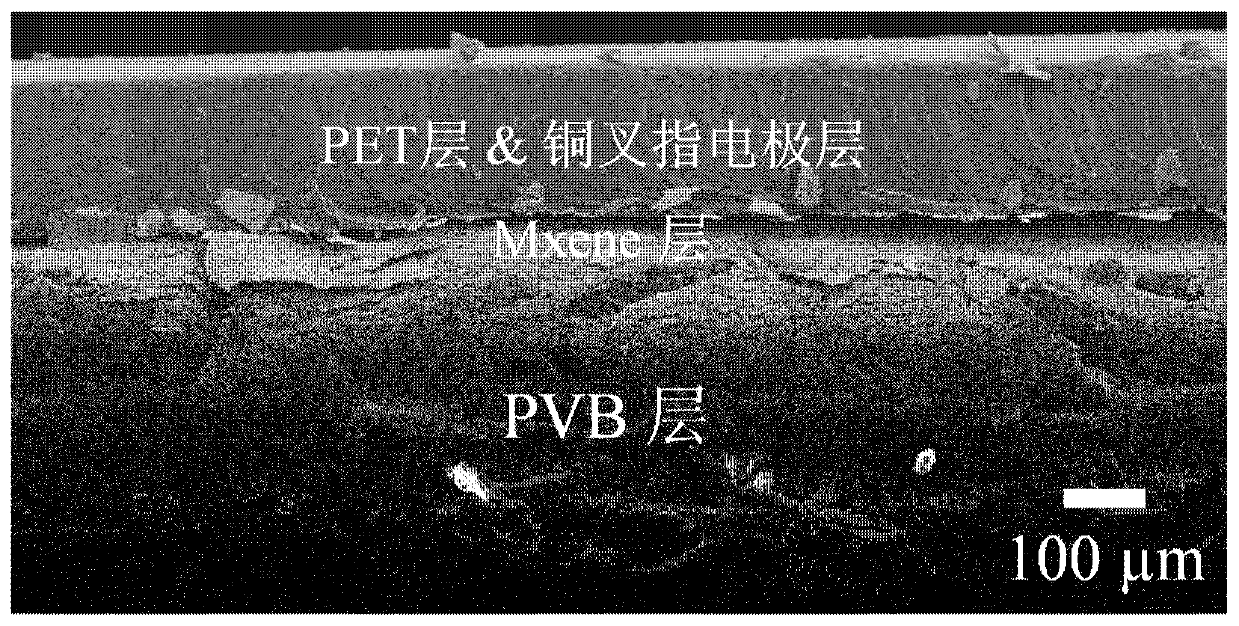

[0048] The MXene layer can be prepared by spraying or vapor deposition. The spraying method includes spraying the prepared MXene aqueous solution to cover the electrode layer 112, and the vapor deposition method includes deposition by chemical vapor deposition (CVD).

[0049] In some embodiments, the intermediate layer further includes: a silver nanomaterial layer, which is disposed between the MXene layer and the polyvinyl butyral layer. The material of the silver nanomaterial layer may be silver nanowires, which are prepared by known techniques in the prior art.

[0050] In some embodiments, the thickness of the MXene layer is between 200nm and 2mm, the thickness less than 2mm can maintain flexibility and local wearability, and the thickness greater than 200nm can ensure that it does not break.

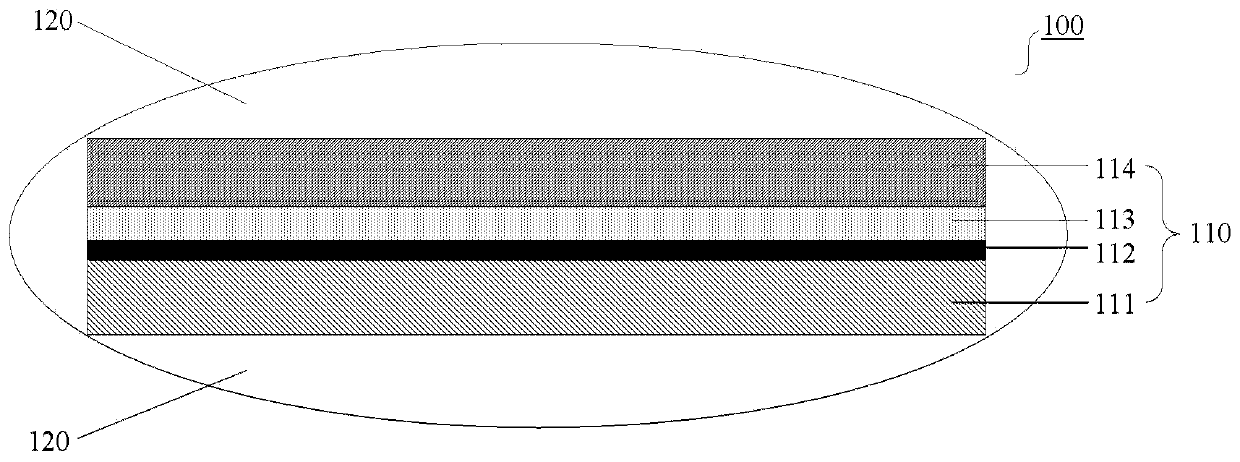

[0051] A polyvinyl butyral (PVB) layer 114 of the present disclosure is disposed on the MXene layer 113 . The polyvinyl butyral (PVB) layer is a layer structure containing polyviny...

Embodiment 1

[0060] The preparation method of the flexible wearable piezoresistive sensor based on MXene / PVB of the present embodiment 1, the steps are as follows:

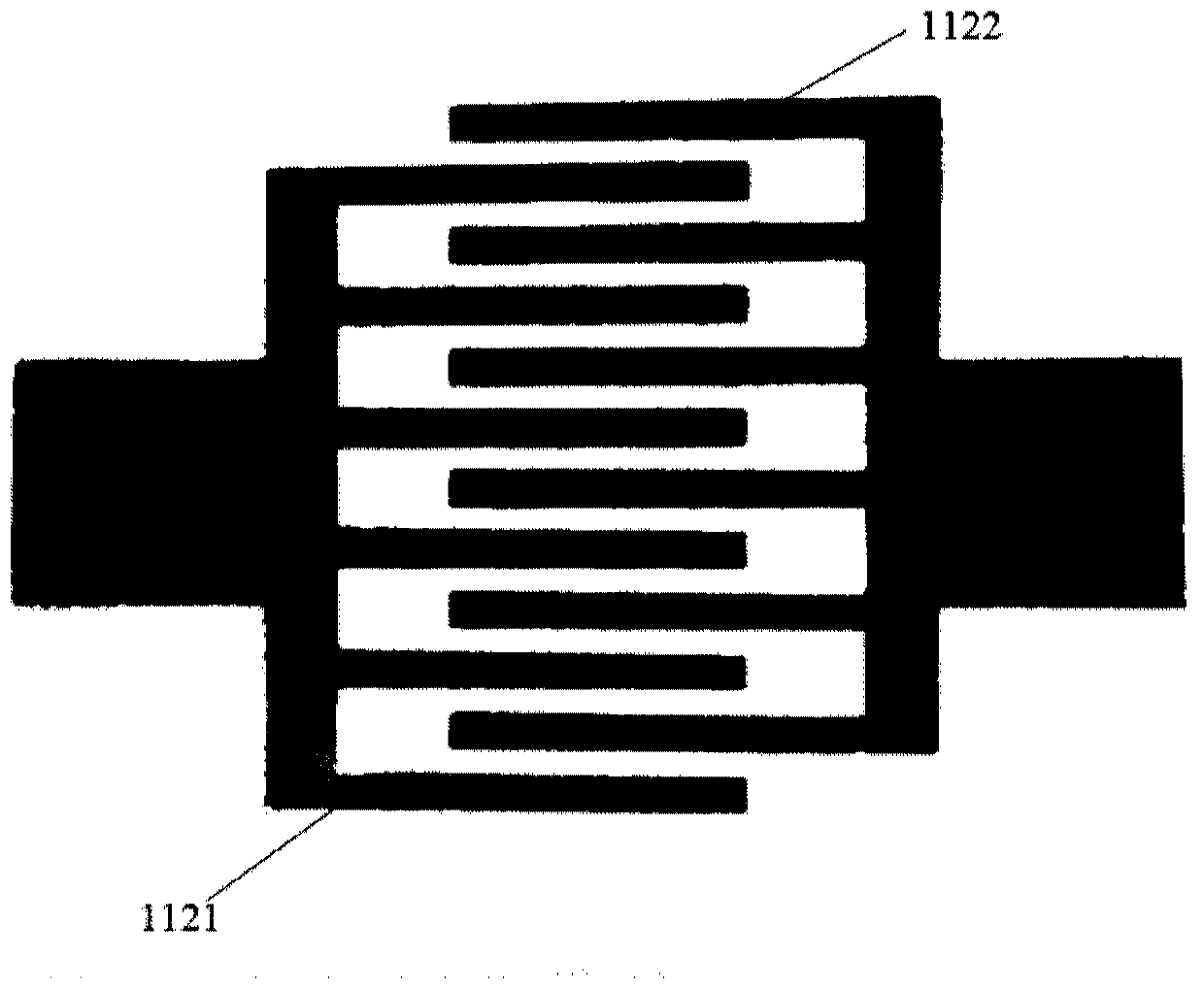

[0061] a. Design the size of the interdigitated electrode (a way of electrode layer) on the computer design software, and then use the method of laser ablation to prepare the conductive electrode, and use conductive adhesive tape or conductive silver paste to lead out two conductive lines. Fabricate interdigitated electrodes on pure PET with conductive ink;

[0062] b. Spray the prepared MXene aqueous solution onto the interdigitated copper electrode with a flexible substrate PET to form an MXene layer;

[0063] c. Then spray PVB ethanol solution to cover the MXene layer, forming a polyvinyl butyral layer on it;

[0064] d. Encapsulate the four layers (middle layer) of PET with flexible substrate, interdigitated copper electrode layer, MXene layer and PVB layer with polydimethylsiloxane, and dry them in an atmosphere of 50-70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com