Back contact heterojunction solar cell and manufacturing method thereof

A technology of solar cells and heterojunctions, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of cumbersome manufacturing process, narrow material selection range, easy short circuit, etc., to increase the process window, improve the Efficiency, the effect of improving short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

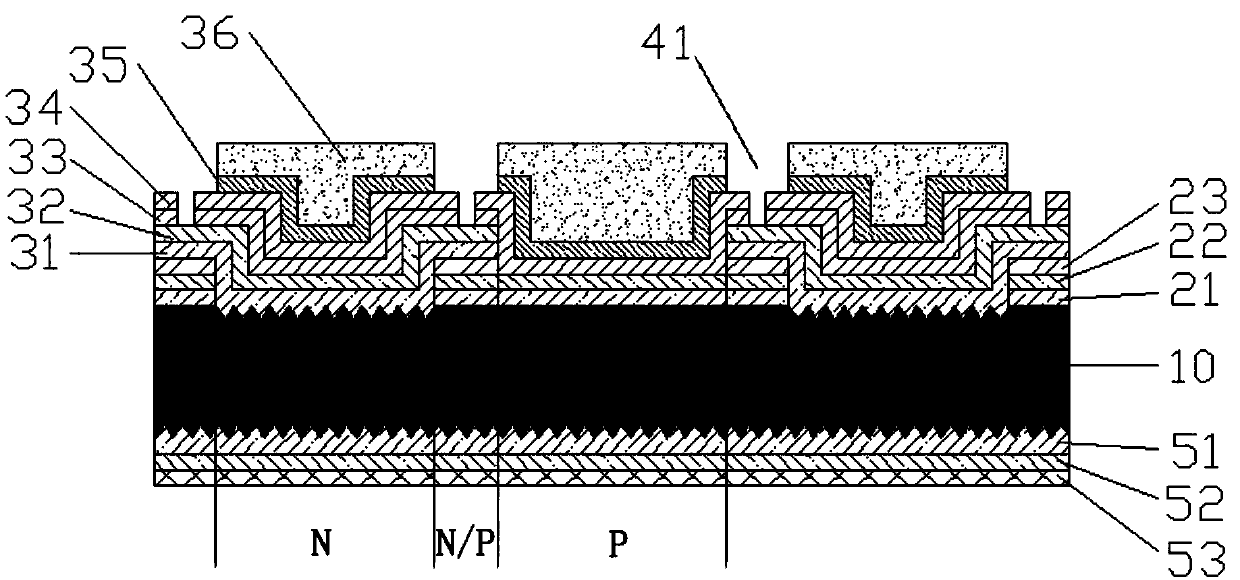

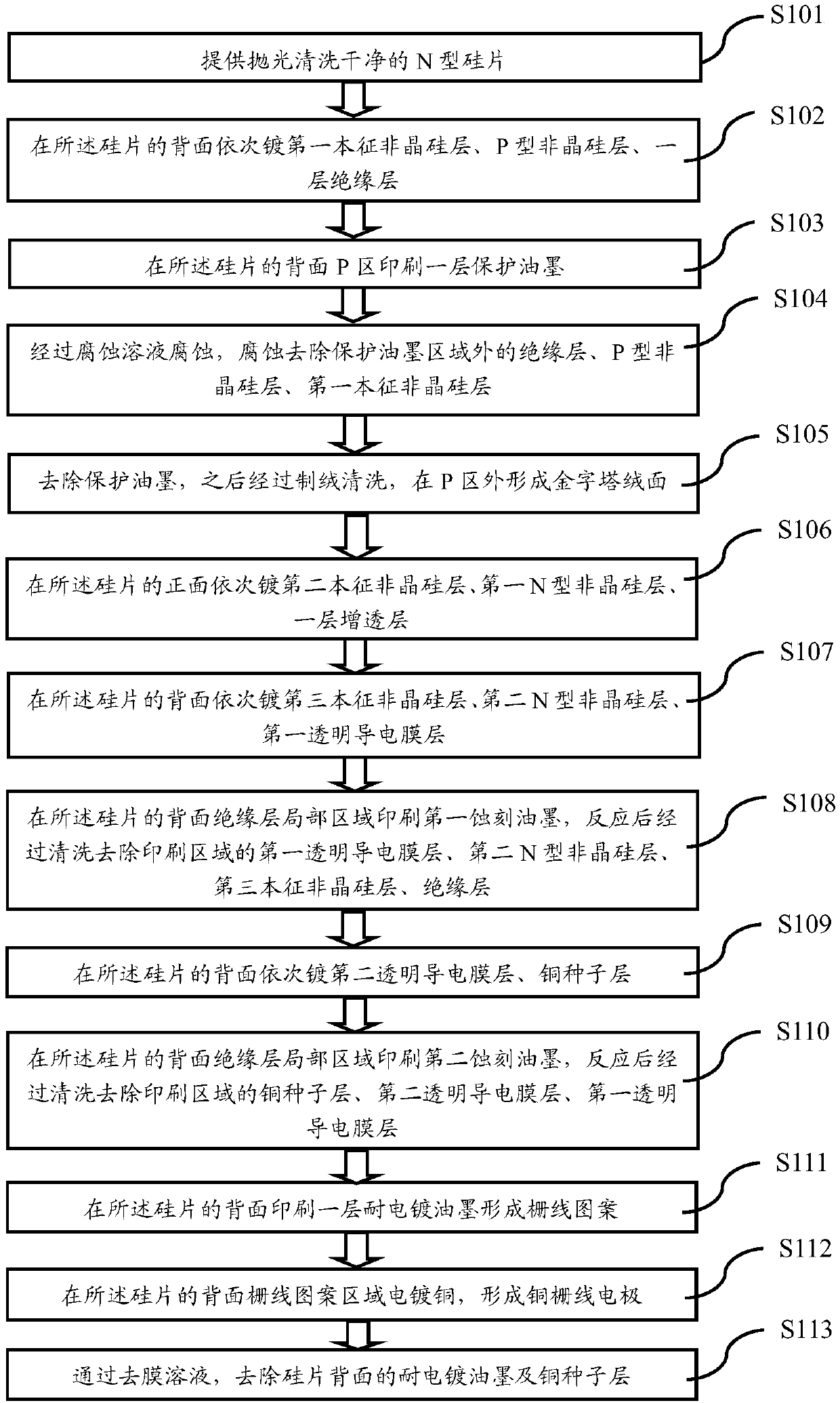

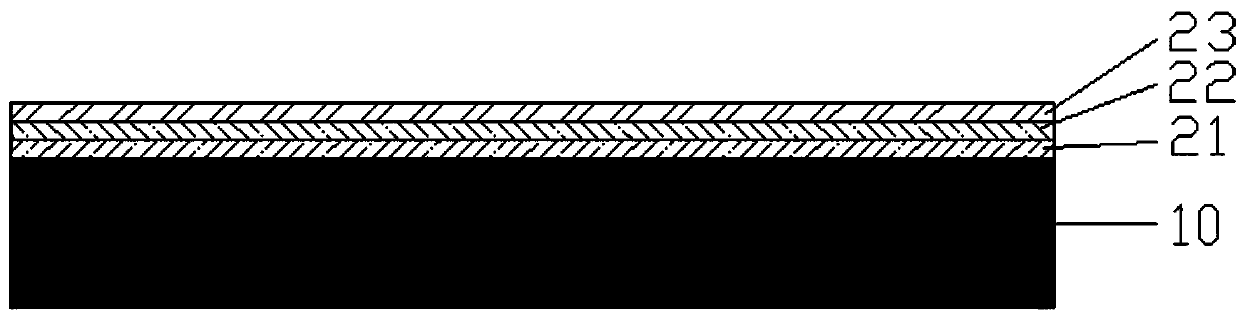

[0037] refer to figure 1 , a back-contact heterojunction solar cell, comprising an N-type monocrystalline silicon wafer 10, a second intrinsic amorphous silicon layer 51 and a first N-type amorphous silicon layer successively arranged on the pyramidal textured surface of the front surface of the silicon wafer 10 52. A layer of anti-reflection layer 53, which is sequentially arranged on the first intrinsic amorphous silicon layer 21, the P-type amorphous silicon layer 22, the second transparent conductive film layer 34, and the copper seed layer 35 on the surface of the P region on the back of the silicon wafer 10. , copper grid line electrode 36, the third intrinsic amorphous silicon layer 31, the second N-type amorphous silicon layer 32, the first transparent conductive film layer 33, the first transparent conductive film layer 33, the third intrinsic amorphous silicon layer 31, the second N-type amorphous silicon layer, etc. Two transparent conductive film layers 34, a coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com