Powder metallurgy compact detecting, stacking and dishing full-automatic production line and working method thereof

A powder metallurgy and fully automatic technology, which is applied in the direction of metal processing equipment, manufacturing tools, grinding feed movement, etc., can solve the problems of low efficiency, high labor cost, insufficient automation technology, etc., and achieve the effect of reducing travel and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

[0042] The design of the present invention mainly proceeds from the perspectives of improving efficiency, saving labor cost and improving compact quality stability, and designs a powder metallurgy compact detection code disc automatic production line.

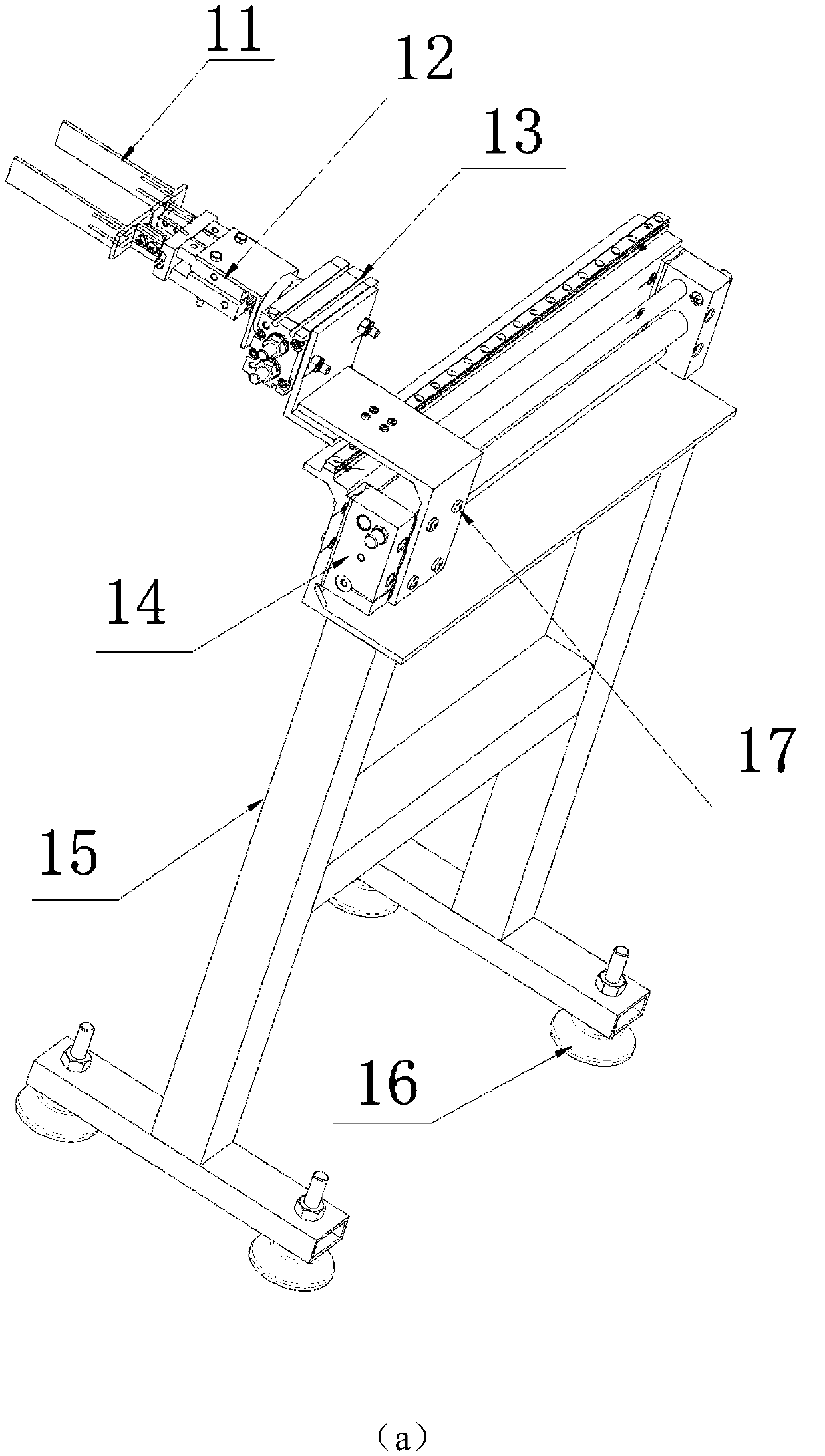

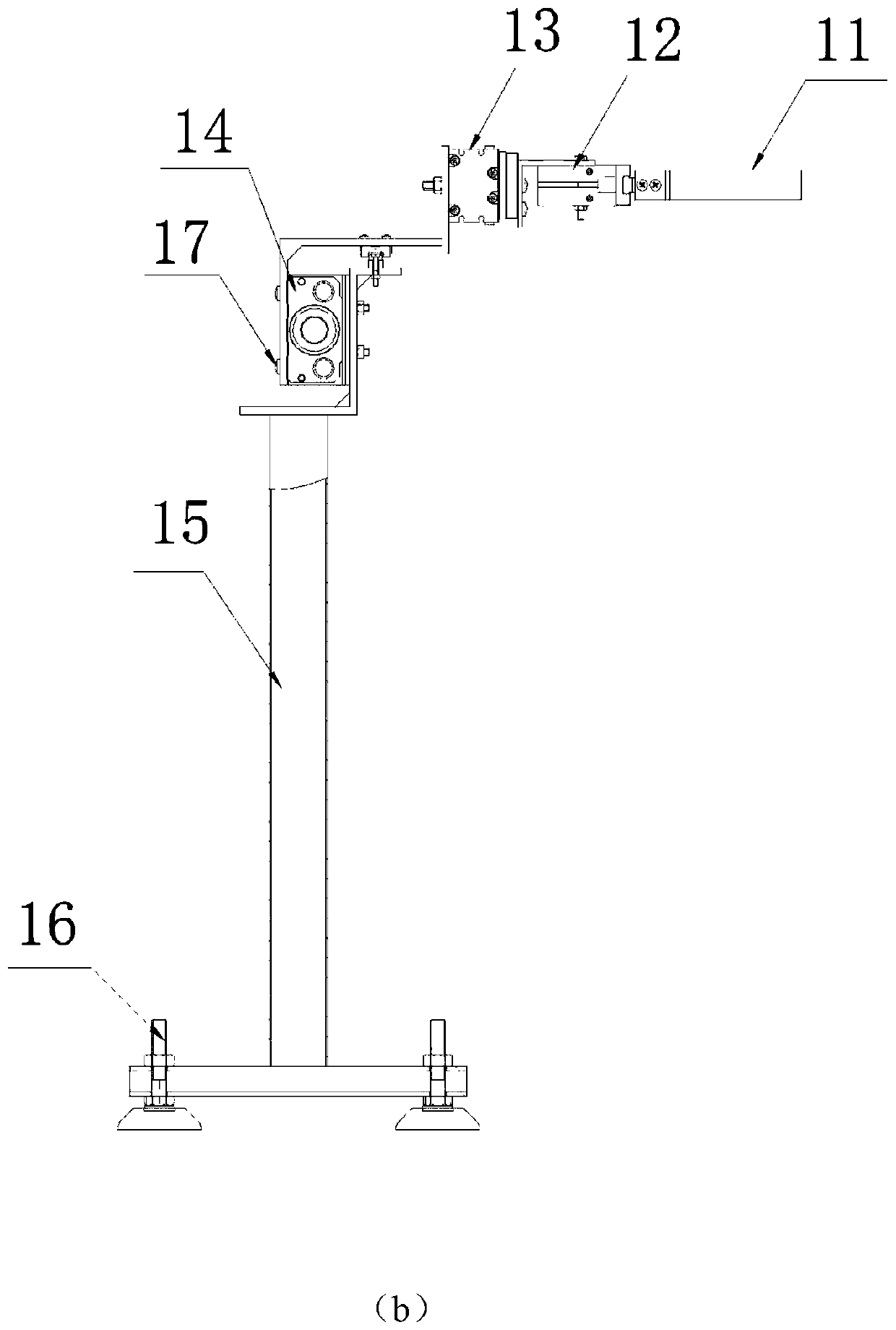

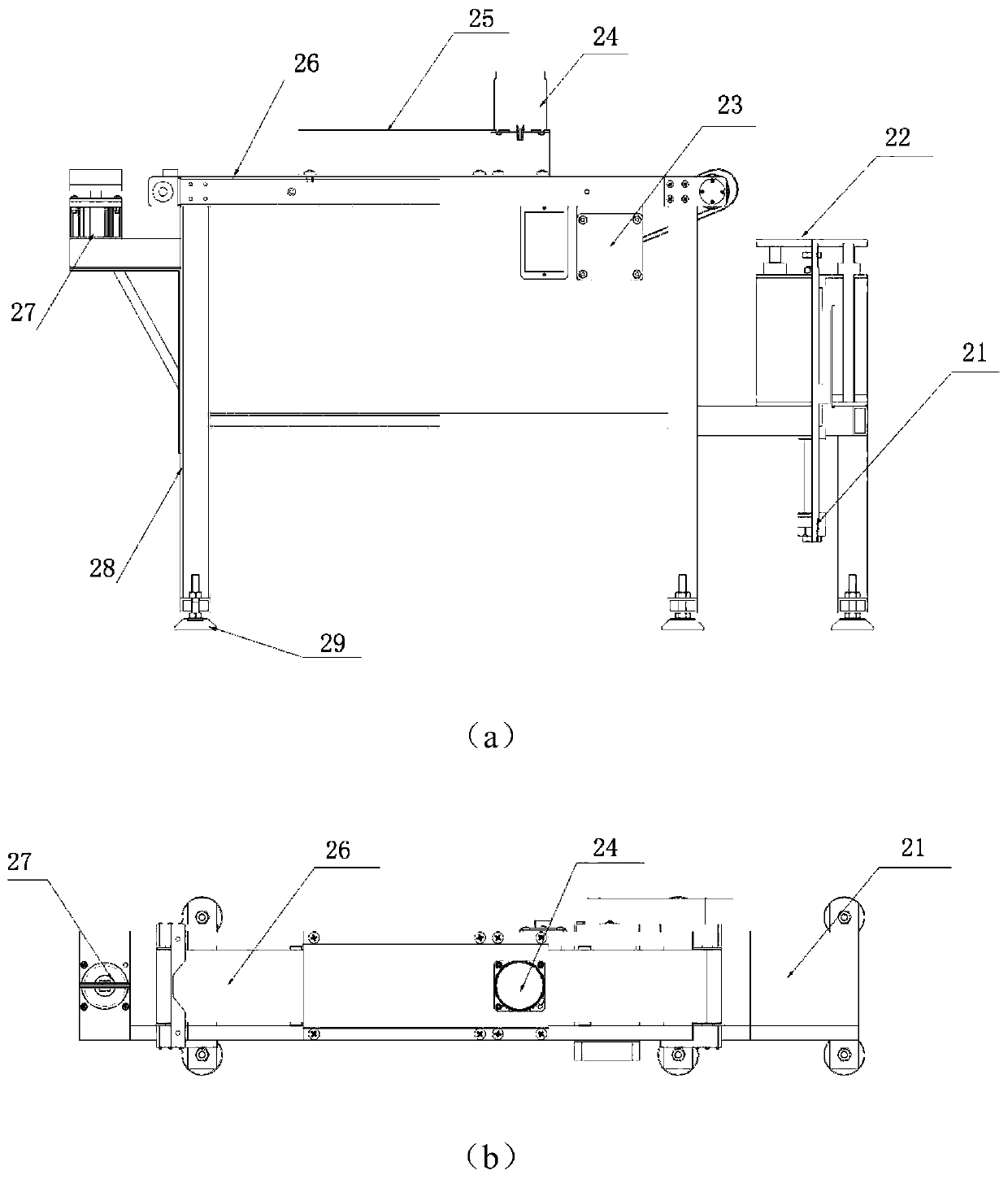

[0043] Such as Figure 11 As shown, the powder metallurgy compact detection code disc automatic production line according to the present invention includes a reclaiming manipulator 10, a deburring and transmission integrated device 20, a material moving manipulator device 30, a weighing sensor 40, and a waste material centralized collection device 50, x Direction stacking and conveying device 60 , double-station stacking and loading manipulator 70 , tray transporting trolley 80 , code disc transporting device 90 and sintering transporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com