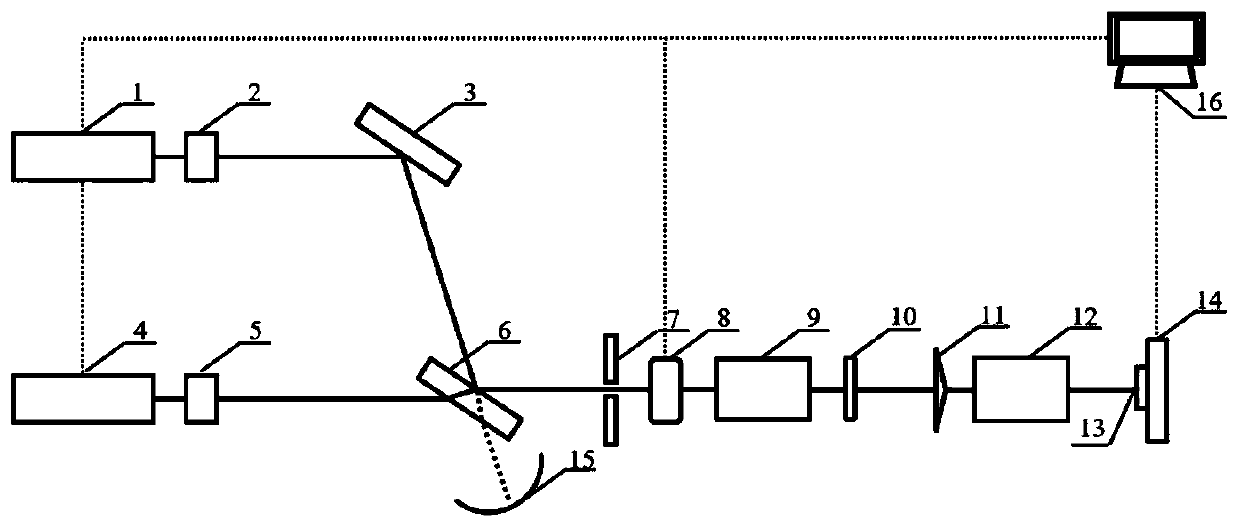

Complex pulse laser deep hole machining device based on Bessel beams

A Bessel beam and composite pulse technology, applied in the field of composite pulse laser deep hole processing devices, can solve the problems of low efficiency, low positioning accuracy of composite pulse laser processing, etc., and achieve the goal of improving processing accuracy and ensuring transmission stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

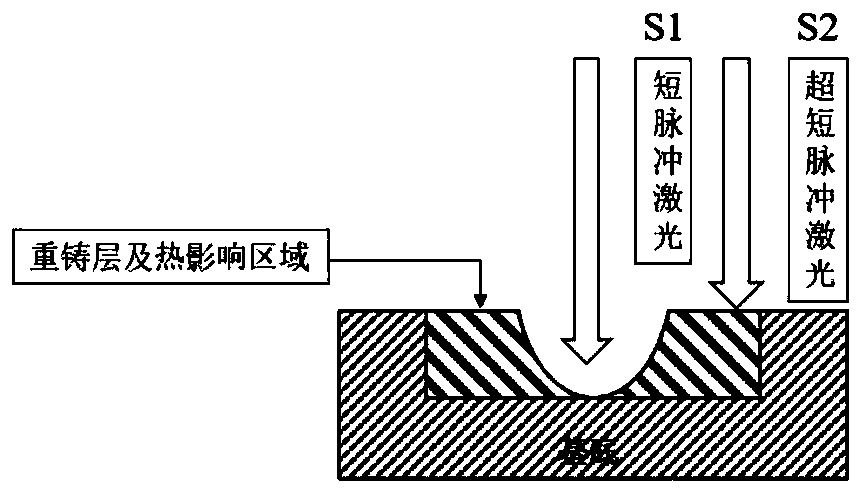

[0027] Such as figure 2 As shown, it includes: step S1 of compound pulse laser step-by-step processing, short pulse laser energy output, to realize the preliminary processing of microholes; step S2 ultrashort pulse energy output, to realize the material removal of micropore recasting layer and heat-affected area generated by S1 .

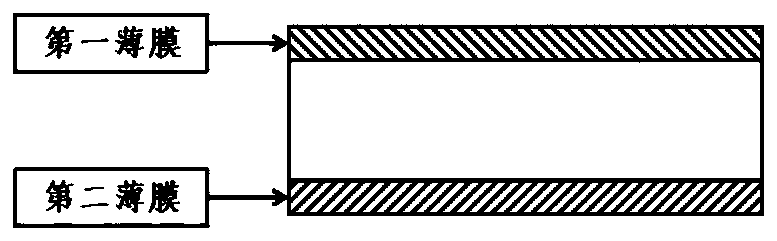

[0028] In the figure, the function of the first thin film on the upper surface of the double-sided coated plane mirror is to enhance the reflectivity of the 1064nm wavelength laser and reduce the transmittance of the 1062nm wavelength laser; the function of the second thin film on the lower surface is to enhance the transmittance of the 532nm wavelength laser , Reduce the reflectivity of 532nm wavelength laser.

[0029] The principle of double-sided coated flat mirror: the film that enhances the transmitted light is called an anti-reflection film, and the film that enhances the reflected light is called an anti-reflection film. Its principle is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com