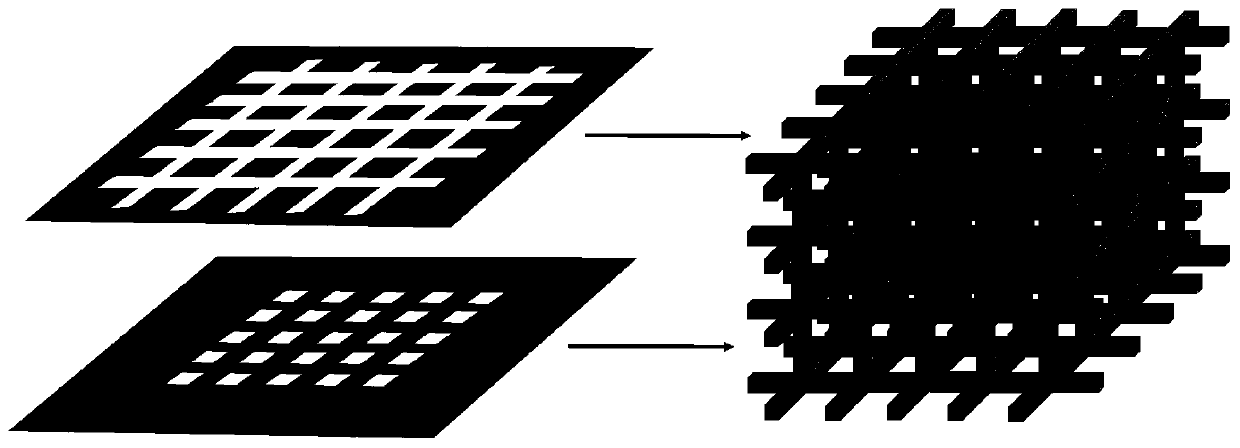

Method for constructing 3D micro-nano channel structure through laser direct-writing technology

A laser direct writing, channel structure technology, applied in 3D object support structure, additive manufacturing, processing material handling, etc., can solve the problems of fineness limitation, inability to obtain topological hollow structure, complicated process, etc., to achieve simple equipment and mechanical strength. And the effect of excellent mechanical properties and high structural construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for constructing a 3D micro-nano channel structure using laser direct writing technology, comprising the steps of:

[0032] (1) Preparation of hydrogel base flexible material: 3.5g of sodium acrylate, 1g of acrylamide, 3mg of N,N'-methylenebisacrylamide, 8mL of 2M sodium chloride, 2mL of 10x PBS, 3.5mL of pure Mix well with water; then take 1 mL of the above mixed solution, mix it with 20 μL of 10% (v / v) tetramethylethylenediamine, 20 μL of 10% (w / v) ammonium persulfate, and place it at 37°C for reaction 1 hour into a gel, and placed in pure water to expand to several times the volume;

[0033] (2) Cut the hydrogel swelled in step (1) into square blocks with a side length of 2 cm, and place them in Fluorescein-NH at a concentration of 500 μM 2 oIn the solution for 1 hour, so that the dye completely penetrates into the interior of the hydrogel;

[0034] (3) Prepare the model file of the structural region where different materials are combined by drawing softwa...

Embodiment 2

[0041]A method for constructing a 3D micro-nano channel structure using laser direct writing technology, comprising the steps of:

[0042] (1) Preparation of hydrogel base flexible material: 4g sodium acrylate, 1g acrylamide, 1.5mg N,N'-methylenebisacrylamide, 8mL of 2M sodium chloride, 2mL of 10xPBS, 3.5mL of pure water Mix well; then take 1 mL of the above mixed solution, mix it with 20 μL of 10% (v / v) tetramethylethylenediamine, 20 μL of 10% (w / v) ammonium persulfate, and place it at 37°C for 1 Hours into a gel, and placed in pure water to expand to several times the volume;

[0043] (2) Cut the hydrogel expanded in step (1) into a square block with a side length of 2 cm, and place it in a Fluorescein-azide solution with a concentration of 1 mM for 1 hour, so that the dye can completely penetrate into the interior of the hydrogel;

[0044] (3) Prepare the model file of the structural region where different materials are combined by drawing software, and import it into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com