High-tensile composite film and preparation method thereof

A composite film and thin film technology, which is applied to chemical instruments and methods, flat products, and other household appliances, etc., can solve problems affecting the normal use of the film, local fractures, etc., to increase the packaging effect, reduce the possibility of fracture, and improve tensile strength. The effect of elongation and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

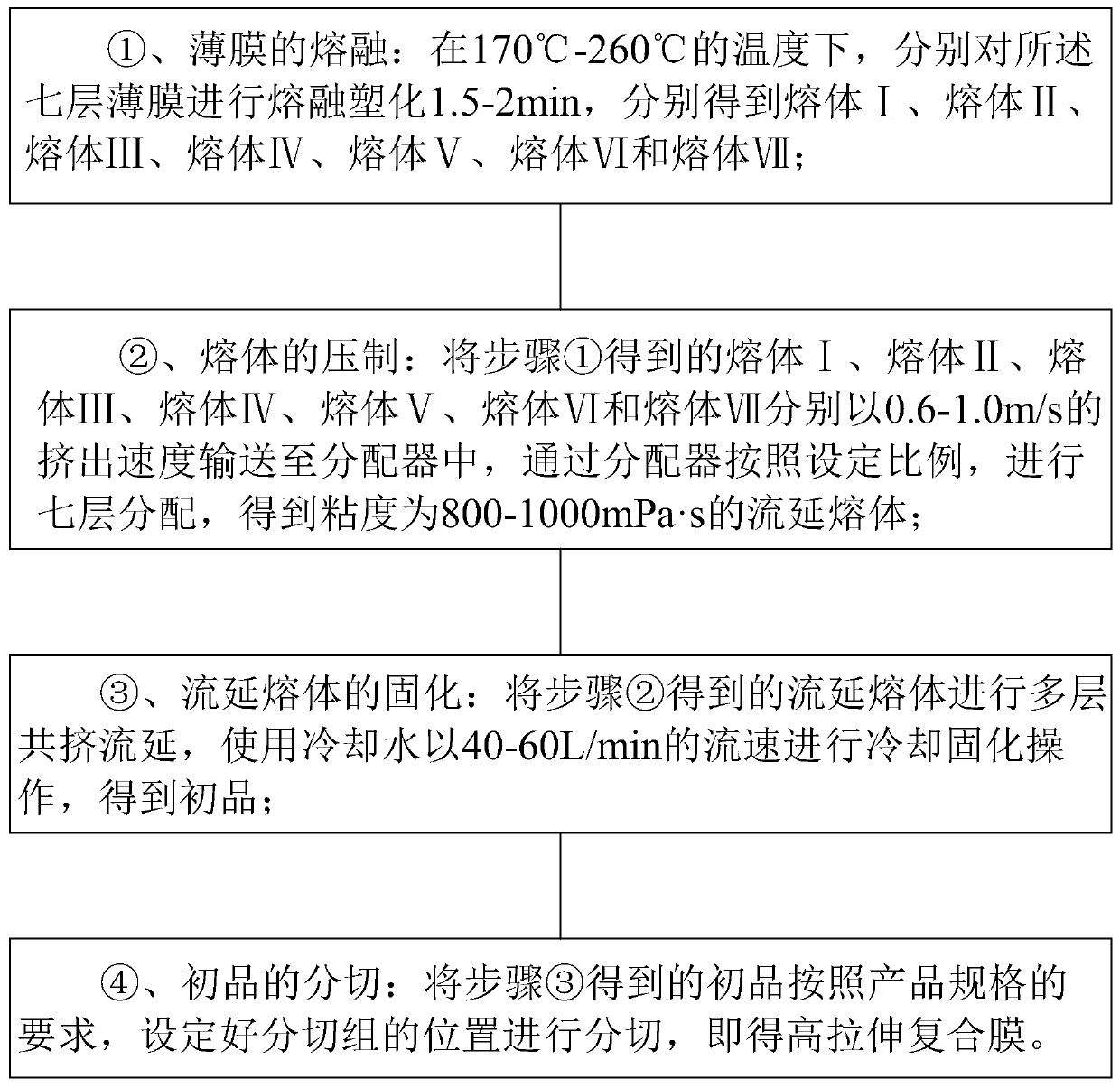

Method used

Image

Examples

Embodiment Embodiment 1

[0059] A high-stretch composite film, composed of seven layers of film, with a thickness of 15 μm, including:

[0060] The first layer of film has a thickness of 10% of the composite film, including the following components in parts by weight: 50 parts of polyethylene 2010, 30 parts of polyethylene 6202 and 2 parts of ABS;

[0061] The second layer of film, the thickness of which is 10% of the composite film, includes the following components in parts by weight: 50 parts of polyethylene 3518, 30 parts of polyethylene 4404 and 4 parts of polypropylene resin W725;

[0062] The third layer of film has a thickness of 15% of the composite film, including the following components in parts by weight: 60 parts of polyethylene 3518, 20 parts of polyethylene 2607 and 2 parts of polypropylene resin W725;

[0063] The fourth layer of film has a thickness of 30% of the composite film, including the following components in parts by weight: 50 parts of polyethylene 3518, 25 parts of polyethy...

Embodiment 2-5

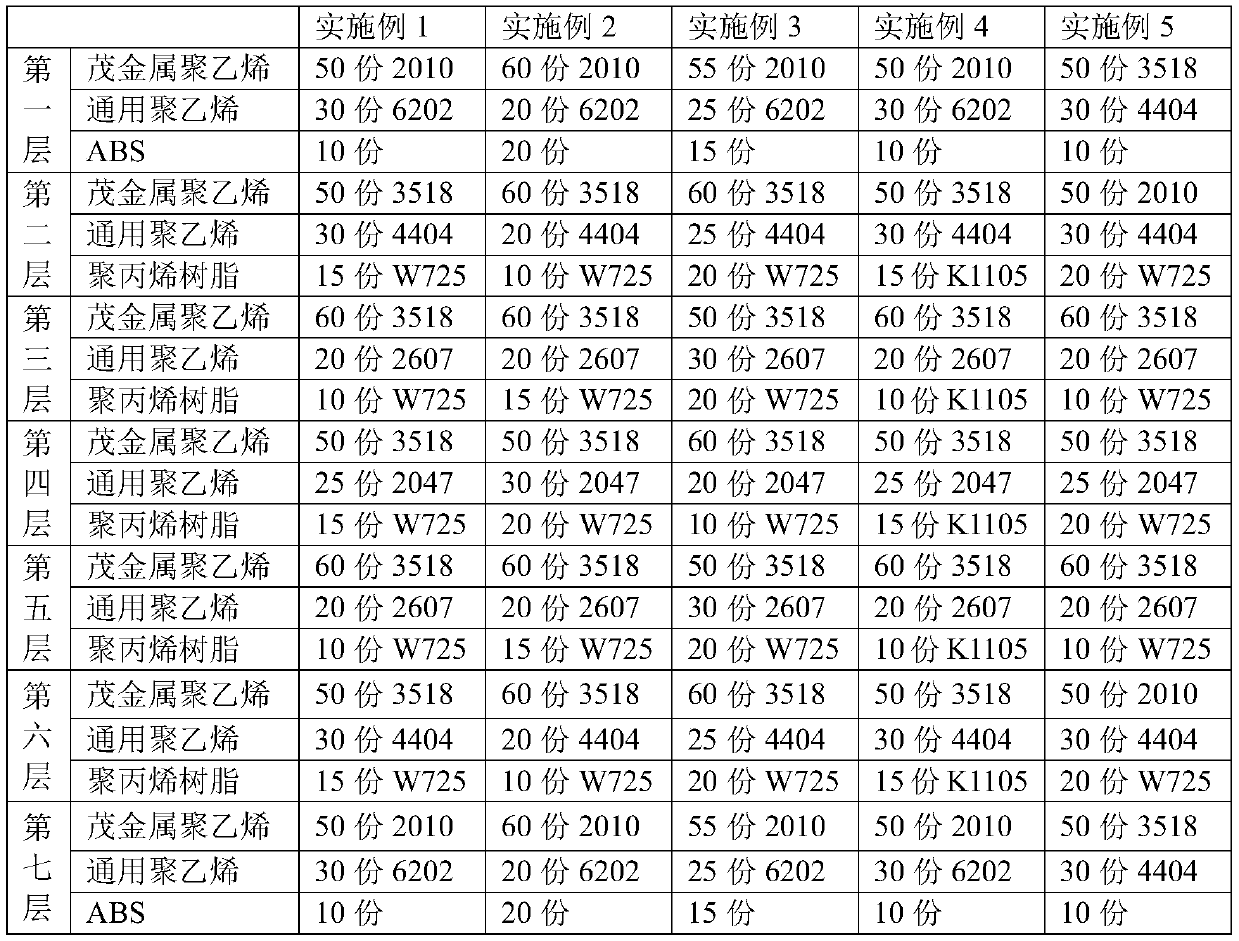

[0074] In Examples 2-5, on the basis of the method in Example 1, the components and dosage of the composite membrane were adjusted, and the specific adjustments are shown in Table 1 below.

[0075] Components and consumption of the composite membrane of table 1 embodiment 1-5

[0076]

Embodiment 6

[0078] In this embodiment, on the basis of the method in Example 1, 2-5 parts of tackifying masterbatch PIB60 are added to the first layer of film and the seventh layer of film respectively, specifically taking the addition of 2 parts as an example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com