Preparation method of carbon-based electrode material and application thereof

A kind of electrode material, carbon-based technology, applied in the field of preparation of carbon-based electrode materials, can solve the problems that it is difficult to meet the requirements of complex structure of electronic equipment, it is difficult to meet the requirements of thick electrodes and shape customization at the same time, and achieve excellent capacitance storage capacity and cycle stability, abundant raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a carbon-based electrode material, comprising:

[0048] (1) Get the orange peel with a thickness of 900 μm and softness, and cut the orange peel into a plane rectangle;

[0049] (2) Put the rectangular orange peel into a freeze dryer at -20°C to -60°C, freeze-dry for 24-72 hours until the peel is completely dry, so as to achieve the shape fixation;

[0050] (3) Put the orange peel with a fixed flat rectangle into a tube furnace, carbonize it at 800 °C for 2 hours in an argon atmosphere, and then cool it to room temperature in an argon atmosphere to obtain a carbon-based electrode material with a thickness of 850 μm. .

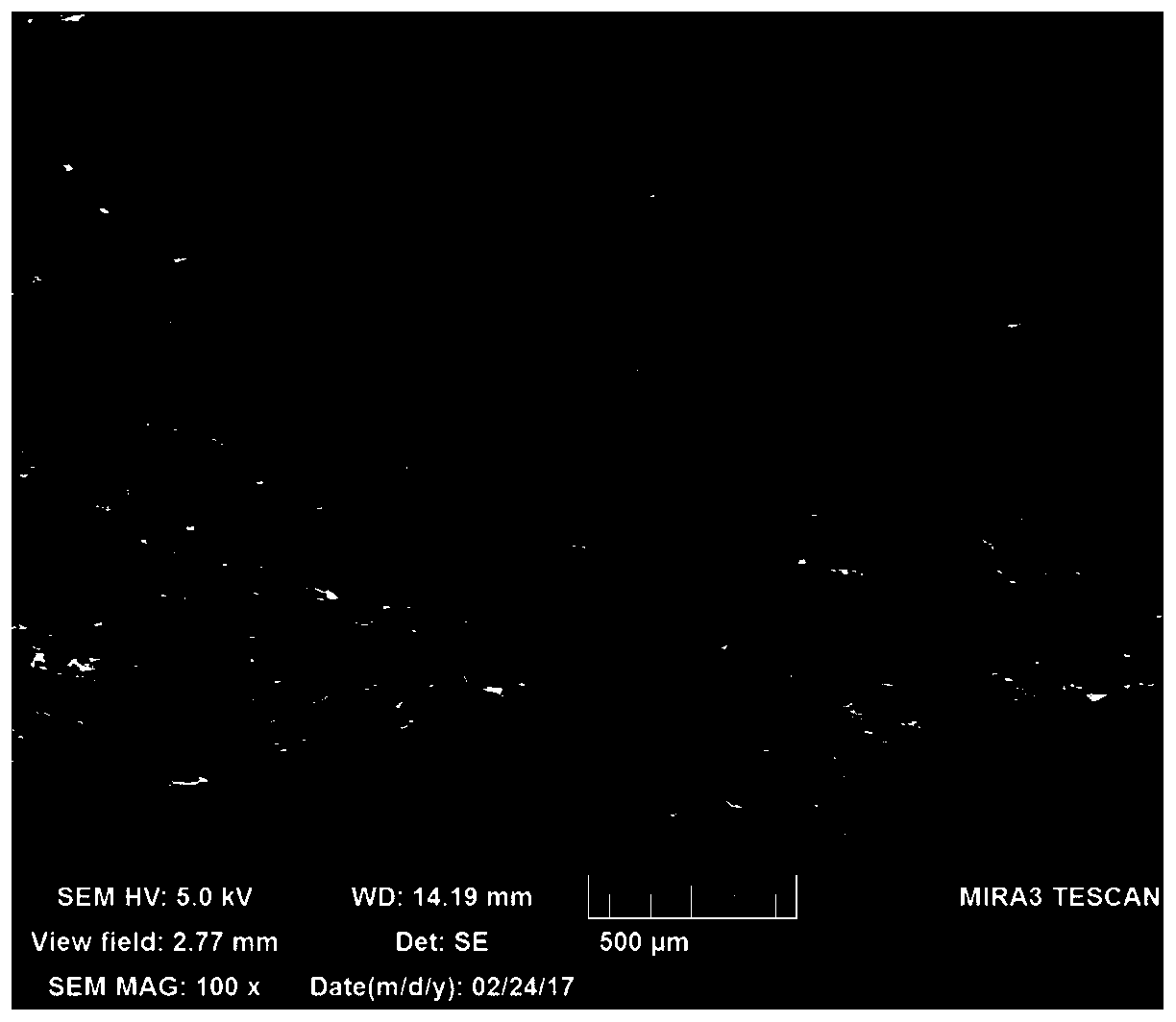

[0051] like figure 1 As shown, the natural orange peel has a microscopic pore structure, and these pore structures are interconnected.

[0052] like figure 2 As shown, the monolithic carbon-based electrode material obtained based on orange peel maintains a good macroscopic shape due to the direct carbonization of orange peel w...

Embodiment 2

[0057] A method for preparing a carbon-based electrode material, comprising:

[0058] (1) Take the orange peel with a thickness of 1000 μm and softness, and cut the orange peel into a plane pentagon;

[0059] (2) Put the pentagonal orange peel into a freeze dryer at -20°C to -60°C, freeze-dry for 24-72 hours until the peel is completely dry, so as to achieve the shape fixation;

[0060] (3) Put the orange peel with a fixed pentagon into a tube furnace, and carry out carbonization treatment at 800°C in an argon atmosphere for 2 hours, and then cool it to room temperature in an argon atmosphere to obtain a whole piece of orange peel with a thickness of 960 μm. carbon-based electrode materials.

Embodiment 3

[0062] A method for preparing a carbon-based electrode material, comprising:

[0063] (1) Take the orange peel with a thickness of 1100 μm and softness, cut the orange peel into strips, and then curl it into a spiral shape;

[0064] (2) Put the spiral-shaped orange peel into a freeze dryer at -20°C to -60°C, freeze-dry for 48 hours until the peel is completely dry, so as to fix the shape;

[0065] (3) Put the orange peel with a fixed spiral shape into a tube furnace, and carry out carbonization treatment at 900°C under a nitrogen atmosphere for 2 hours, and then cool it to room temperature under a nitrogen atmosphere to obtain a whole piece of carbon with a thickness of 1050 μm. base electrode material. like Figure 6 As shown, the helical monolithic carbon-based electrode material prepared from orange peel maintains a continuous monolithic carbon structure while achieving a helical shape at a thickness of 100 μm, which makes it suitable for specific application scenarios, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com