Light release regulator for silicon release agent, and synthesis method and application thereof

A synthesis method and release agent technology, applied in the direction of coating, etc., can solve the problems of poor silicon release performance, low silicon release residual adhesion rate, etc., to improve performance, reduce release force, and small release force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

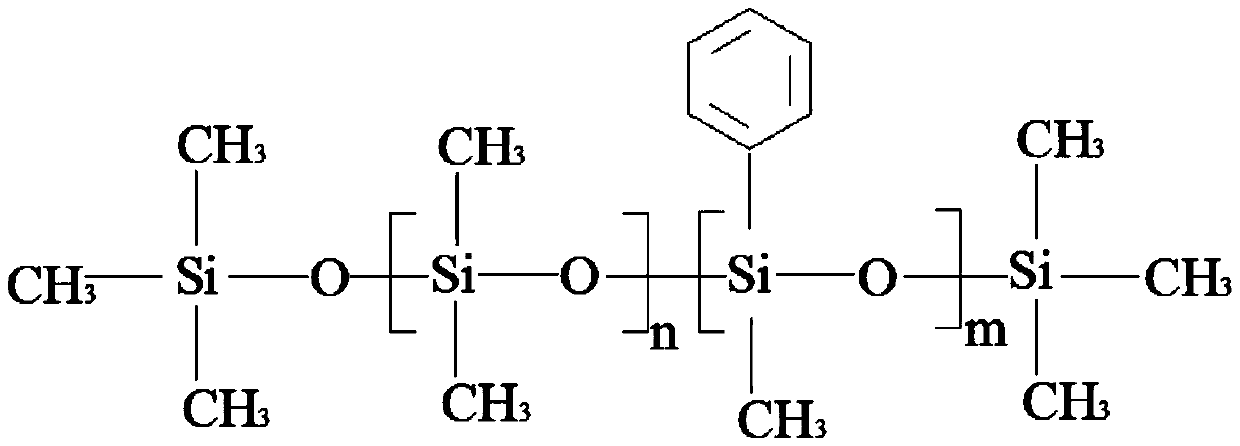

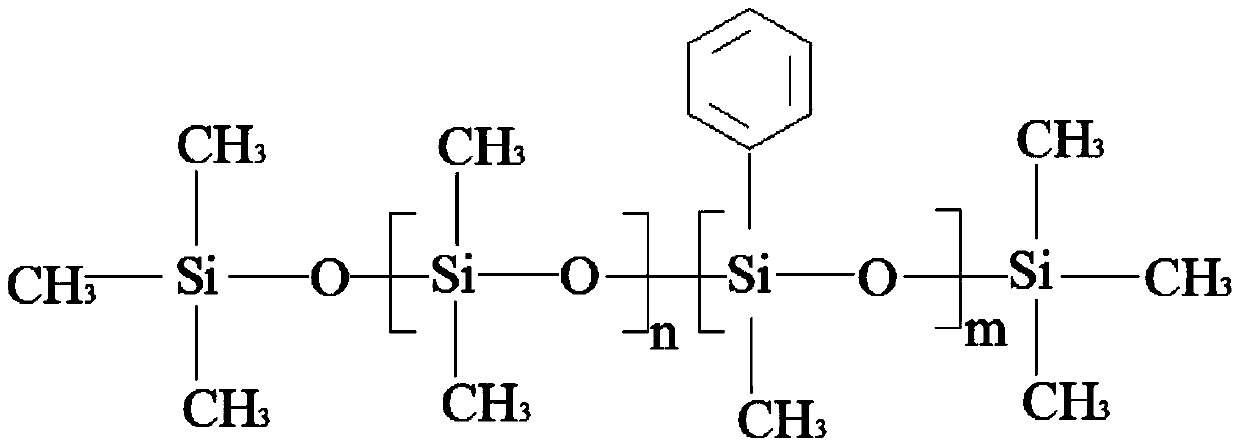

[0026] A kind of light release conditioner for silicon release agent, its structural formula is:

[0027]

[0028] Wherein, n=1-500; m=1-200; the molecular weight range is 350-65000; the viscosity is 10-50000cs.

[0029] Specifically, it is the acid-catalyzed polymerization product of hexamethyldisiloxane, octamethylcyclotetrasiloxane and methylphenylcyclotrisiloxane.

Embodiment 2

[0031] A kind of synthetic method of the light release type conditioner that silicon release agent described in above-mentioned embodiment 1 is used, comprises the following steps:

[0032] S1. Weigh 162.38g of hexamethyldisiloxane, 3707.75g of octamethylcyclotetrasiloxane, and 1634.68g of methylphenylcyclotrisiloxane into the reaction vessel in turn, and slowly stir while stirring Add 166g of concentrated sulfuric acid, raise the temperature to 70°C, and react at a constant temperature of 70°C for 8 hours;

[0033] S2, stop heating, after cooling to room temperature, add 450g of anhydrous sodium carbonate to neutralize the remaining concentrated sulfuric acid, and neutralize for 6 hours;

[0034] S3. After desalting by filtration, reduce the filtrate to 170° C. for 2 hours under reduced pressure, and then cool and discharge to obtain the light release regulator for the silicon release agent.

Embodiment 3

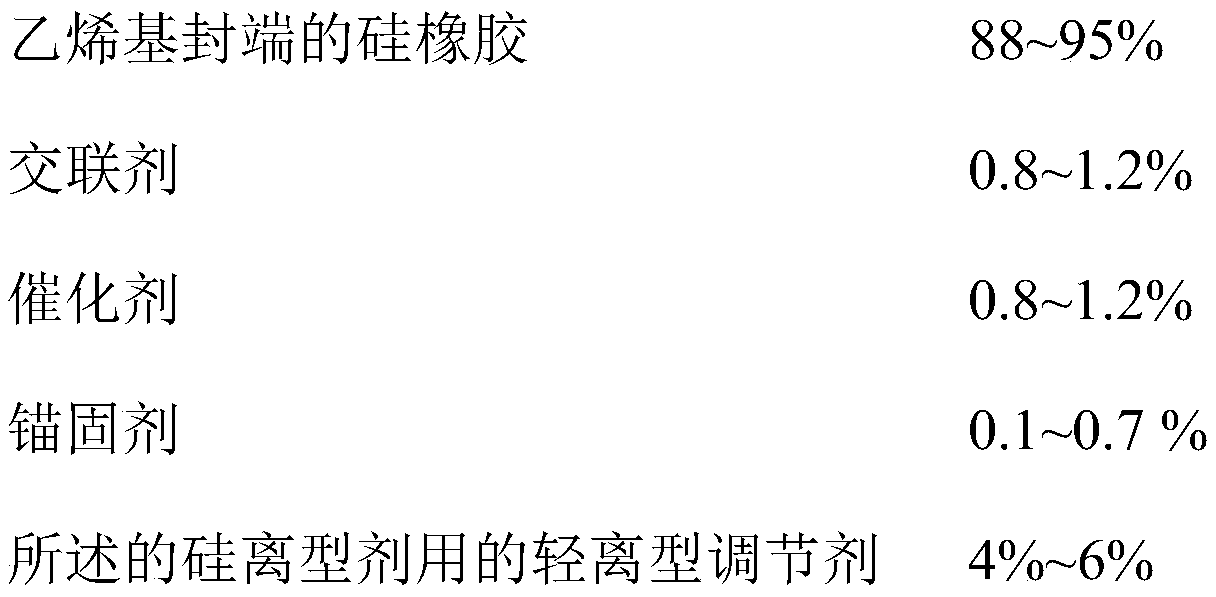

[0036] A kind of application of the light release conditioner that silicon release agent described in above-mentioned embodiment 1 is used, the light release conditioner that described silicon release agent is used is applied in the formula of silicon release agent, by mass Percentage, including the following components:

[0037]

[0038] Wherein, the mole fraction of vinyl in the vinyl-terminated silicone rubber is 1.0%, and the solid content is 30%. The crosslinking agent is silicone oil with a viscosity of 20Cs and a hydrogen content of 1.60%. The platinum concentration of the catalyst is 5000PPm. The anchoring agent is selected from Dow Corning model as SL-297 adhesion additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com