Continuous annealing furnace high-temperature furnace roller ZrB2 modified CoCrAlTaY-Y2O3 protective coating and preparation method thereof

A continuous annealing furnace and protective coating technology, applied in the coating, metal material coating process, furnace, etc., can solve the problems of shortening the service life of the coating, improve stability and service life, and have good high-temperature friction and wear properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

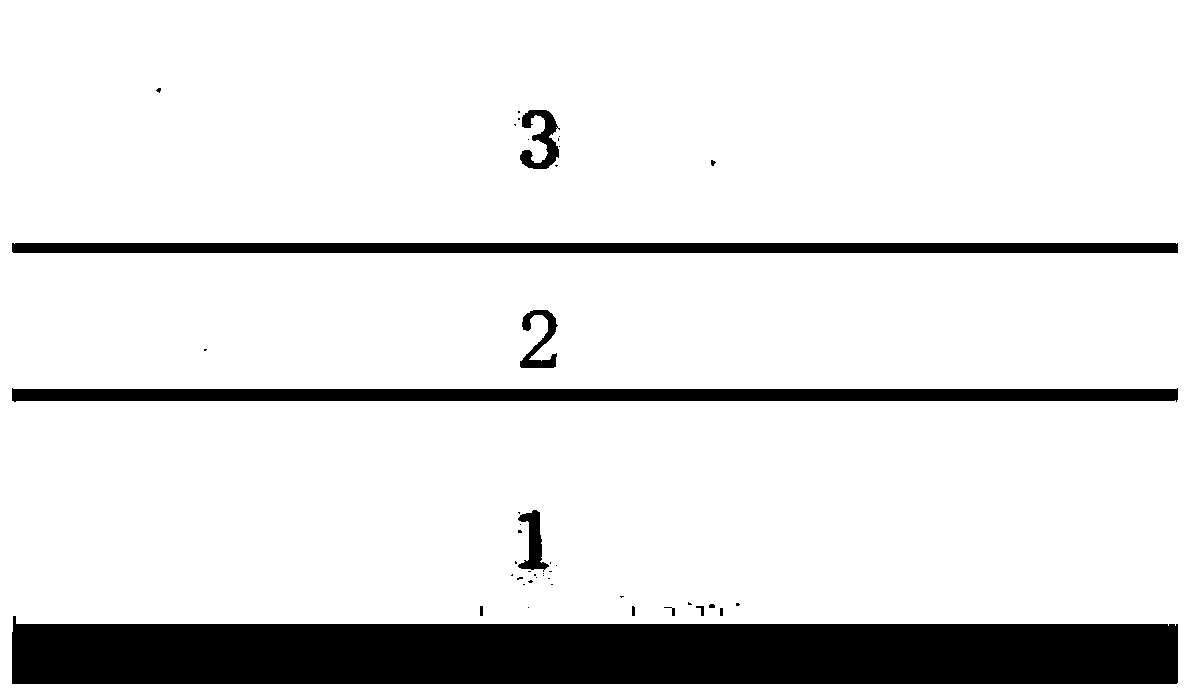

[0036] like figure 1 as shown, figure 1 For the continuous annealing furnace high temperature furnace roll ZrB 2 Modified CoCrAlTaY-Y 2 o 3 Structural schematic diagram of protective coating; continuous annealing furnace high temperature furnace roller ZrB of the present invention 2 Modified CoCrAlTaY-Y2 o 3 The protective coating is provided as a double-layer structure of an adhesive layer 2 and a cermet working layer 3 on the substrate 1 . The cermet working layer 3 is better bonded to the substrate 1 through the bonding layer 2 .

[0037] The composition of the bonding layer 2 is NiCrAlY or NiCoCrAlY; the cermet working layer 3 is CoCrAlTaY-Y 2 o 3 -ZrB 2 , wherein the mass percentage of each component is: 50% to 63% of CoCrAlTaY, 21% to 30% of Y 2 o 3 , 16%~20% ZrB 2 ; That is, the cermet working layer 3 is (wt.%)(50~63)CoCrAlTaY-(21~30)Y 2 o 3 -(16~20)ZrB 2 ; The weight percent of each element in the binder phase and anti-oxidation phase CoCrAlTaY is: 50% to...

Embodiment 2

[0056] In this example, spray granulation is used to prepare 59CoCrAlTaY-25Y suitable for plasma spraying 2 o 3 -16ZrB 2 powder, the specific steps are:

[0057] S11, weigh CoCrAlTaY, Y according to a certain amount 2 o 3 and ZrB 2 The mixed powder is placed in a ball mill jar, and an appropriate amount of absolute ethanol and zirconia grinding balls are added. The mass ratio of mixed powder: absolute ethanol: grinding balls is 1: 1.2: 2. Milling at a ball milling speed of min for 12 hours to obtain a homogeneously mixed cermet mixture.

[0058] S12, adding a polyvinyl alcohol (PVA) solution with a mass concentration fraction of 10% to the cermet mixture to form a cermet slurry, and the solid content mass fraction of the polyvinyl alcohol (PVA) in the cermet slurry is 4 %, continue ball milling for 4 hours to obtain a uniformly mixed slurry with a certain viscosity.

[0059] S13, the slurry obtained in step S12 is spray-dried and granulated in LGZ-8 spray drying equipme...

Embodiment 3

[0072] In this example, spray granulation is used to prepare 55CoCrAlTaY-29Y suitable for plasma spraying 2 o 3 -16ZrB 2 powder, the specific steps are:

[0073] S11, weigh CoCrAlTaY, Y according to a certain amount 2 o 3 and ZrB 2 The mixed powder is placed in a ball mill jar, and an appropriate amount of absolute ethanol and zirconia grinding balls are added. The mass ratio of mixed powder: absolute ethanol: zirconia grinding balls is 1: 1.2: 2. Mill at a ball milling speed of 360r / min for 10 hours to obtain a uniformly mixed cermet mixture.

[0074] S12, adding a polyvinyl alcohol (PVA) solution with a mass concentration fraction of 10% to the cermet mixture to form a cermet slurry, and the solid content mass fraction of the polyvinyl alcohol (PVA) in the cermet slurry is 4 %, continue ball milling for 6 hours to obtain a uniformly mixed slurry with a certain viscosity.

[0075] S13, the slurry is spray-dried and granulated in LGZ-8 spray drying equipment. Wherein, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com