Special purification column for aflatoxin M group and application

An aflatoxin and purification column technology, applied in chemical instruments and methods, separation methods, instruments, etc., can solve the problems of unsatisfactory adsorption effect, increased detection cost, complicated operation steps, etc., and achieves easy mass production and low cost. , the effect of the production method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: the raw material of AFM-P post and preparation

[0063] (1) Raw materials:

[0064] Column tube: the capacity is 3mL, the inner diameter is 1cm, and the length is 5cm; the filling amount of the filler in the column tube is 200mg;

[0065] Sieve plate: polyethylene sieve plate with a pore size of 10 μm;

[0066] Filler: graphitized carbon (PestiCarb) with a particle size of 120 to 400 meshes and nanometer iron tetroxide (Fe 3 o 4 );

[0067] (2) Preparation:

[0068] Install a lower sieve plate at the liquid outlet of the column tube, then mix 150mg of graphitized carbon and 50mg of nanometer iron tetroxide, fill it into the column tube from the liquid inlet end of the column tube, and then install the upper sieve plate into the column tube, among which , the upper sieve plate, the lower sieve plate and the column tube are installed with an interference fit, and then compressed.

Embodiment 2

[0069] Embodiment 2: the raw material of AFM-P column and preparation

[0070] (1) Raw materials: consistent with Example 1;

[0071] (2) Preparation: Install a lower sieve plate at the liquid outlet end of the column tube, then mix 160mg of graphitized carbon and 40mg nanometer ferric oxide, fill it into the column tube from the liquid inlet end of the column tube, and then install the upper sieve plate Into the column tube, wherein, the upper sieve plate, the lower sieve plate and the column tube are installed with interference fit and pressed tightly.

Embodiment 3

[0072] Embodiment 3: the raw material of AFM-P column and preparation

[0073] (1) Raw materials: consistent with Example 1;

[0074] (2) Preparation: Install a lower sieve plate at the liquid outlet end of the column tube, then mix 120mg of graphitized carbon and 60mg nano-iron ferric oxide, fill it into the column tube from the liquid inlet end of the column tube, and then install the upper sieve plate Into the column tube, wherein, the upper sieve plate, the lower sieve plate and the column tube are installed with interference fit and pressed tightly.

[0075] Contrasting the purification columns made in Examples 1 to 3, it is found that the purification column purification effect made in Example 1 is the best, so it can be seen that 150mg PestiCarb and 50mg Fe 3 o 4 Mixing, the AFM-P column made of this combination as solid phase extraction filler can achieve better adsorption effect.

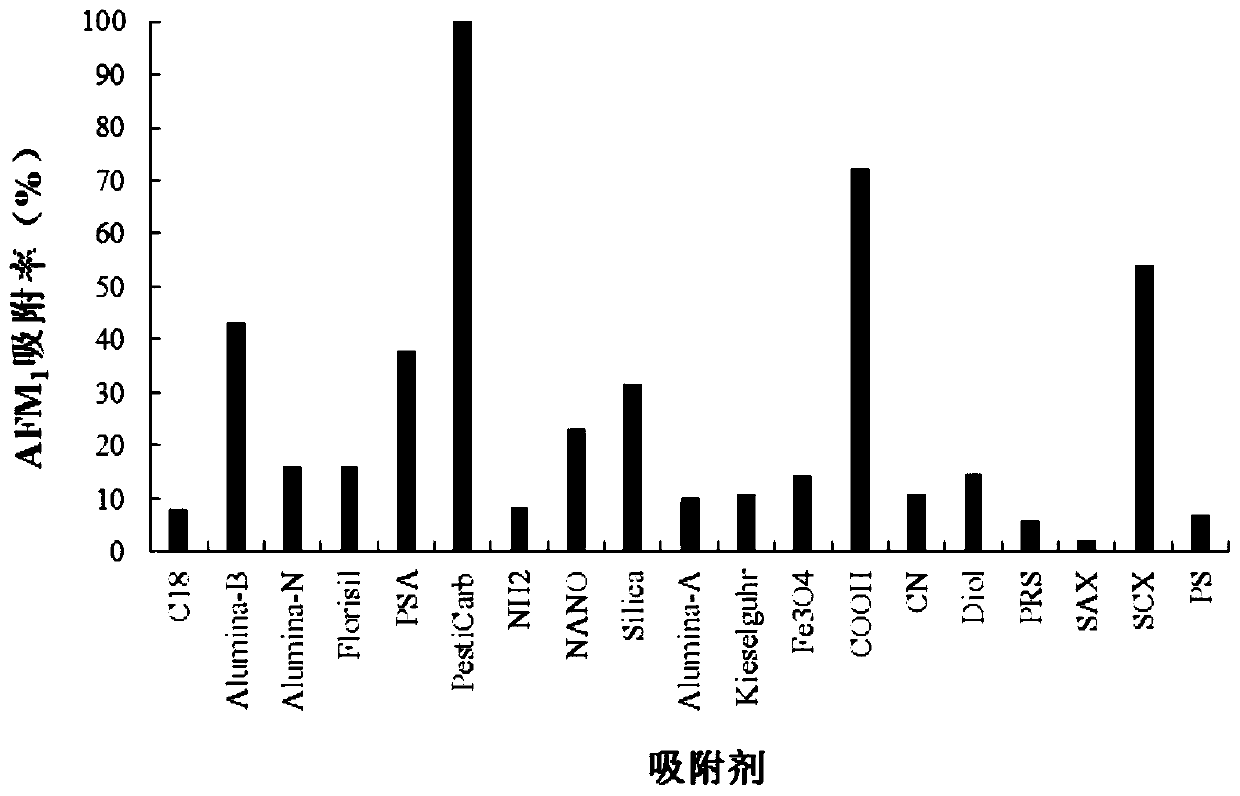

[0076] 2. Comparative example:

[0077] The AFM-P column that embodiment 1 is made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com