Waterwheel-like chain-box-type vertical fuel conveying device

A technology of conveying device and chain box, applied in the field of transmission, can solve the problems such as difficulty in jamming of spherical nuclear fuel elements, jamming of spherical nuclear fuel elements, large building area and space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

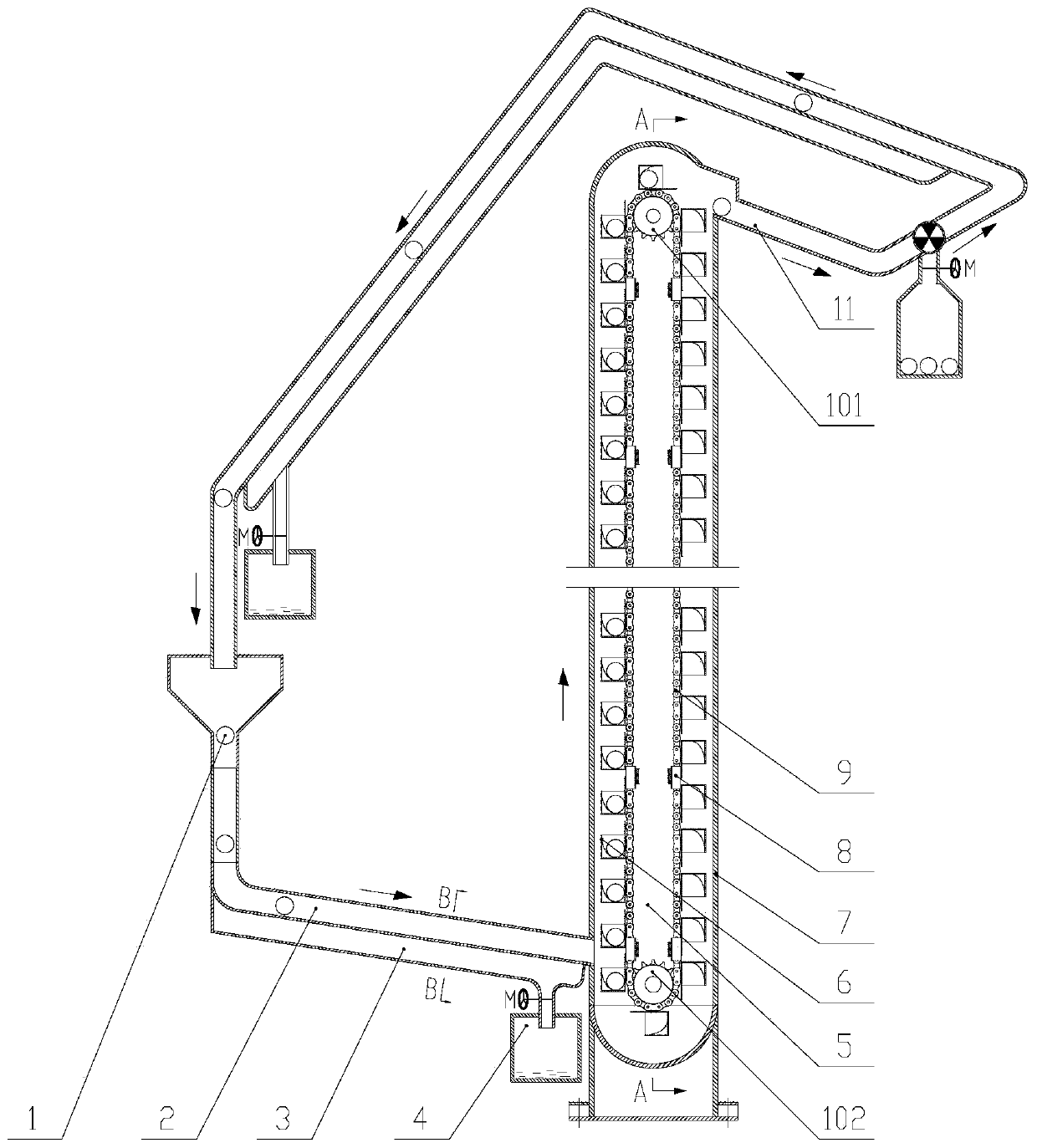

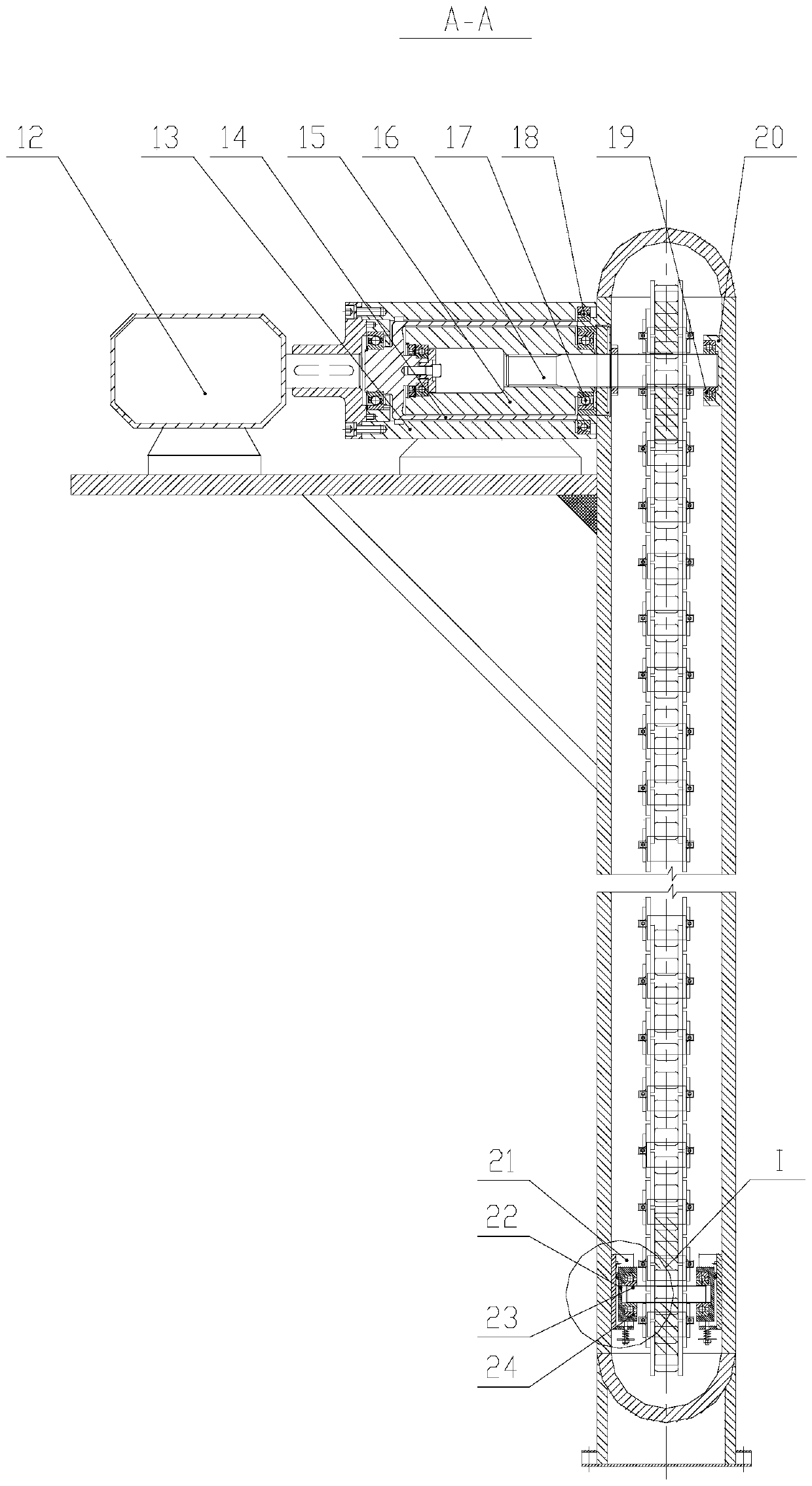

[0026] see figure 1 , is a schematic diagram of the overall structure of a water truck chain box type fuel vertical conveying device according to an embodiment of the present invention, which is used in a high temperature gas-cooled reactor nuclear power plant. The fuel vertical conveying device of the present embodiment comprises a sealed container 7 containing helium, a mechanical transmission part 5 located in the container 7, and a drive assembly located outside the container 7; the upper and lower ends of the container 7 are respectively aligned with the gravity The passive grooved raceways 11 and 2 are connected to form a loop, and the bottom of the grooved raceways 2 and 11 is provided with a dust conveying pipe 3 for collecting dust and debris falling through the grooved raceways. The end of conveying pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com