Building garbage staged treatment device

A technology for graded treatment and construction waste, which is applied in grain treatment, construction waste recycling, solid separation, etc. It can solve complex and complex problems, achieve fast screening speed and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

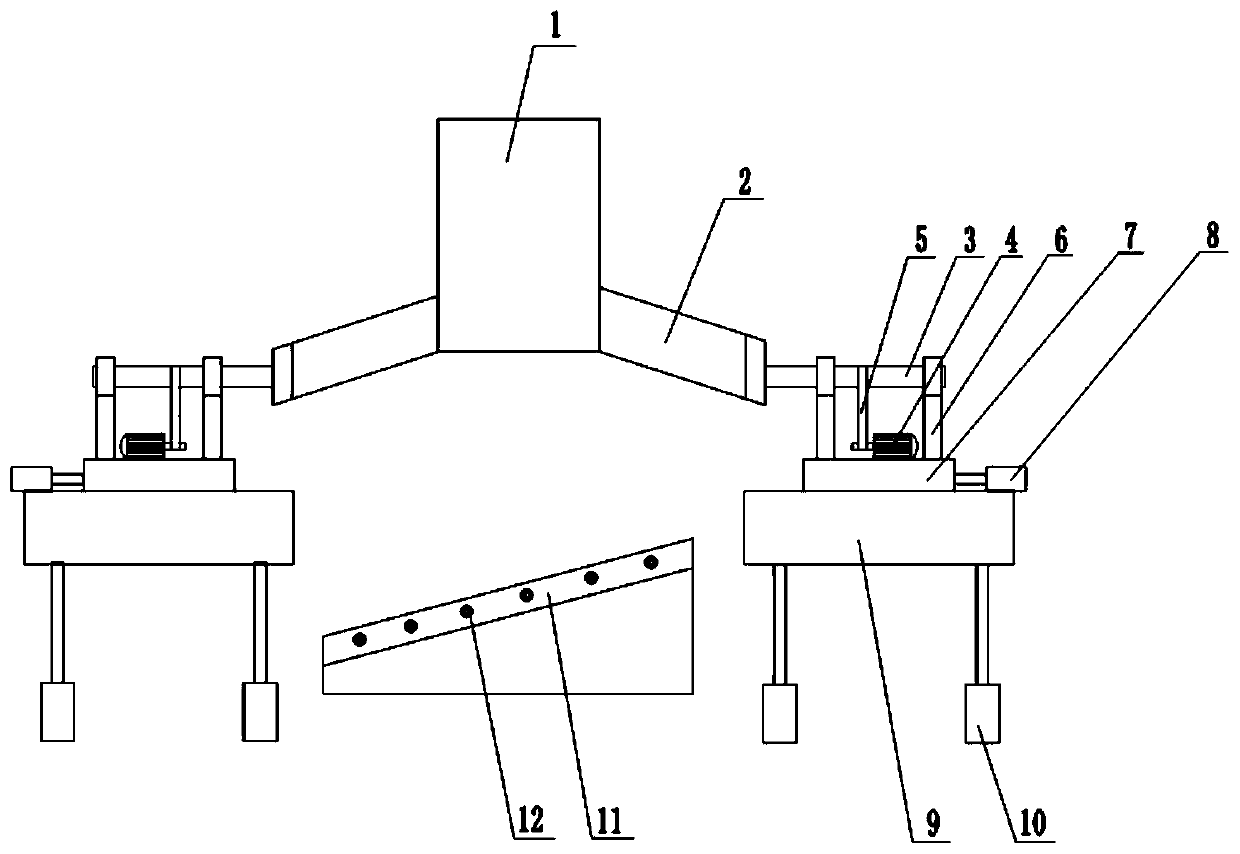

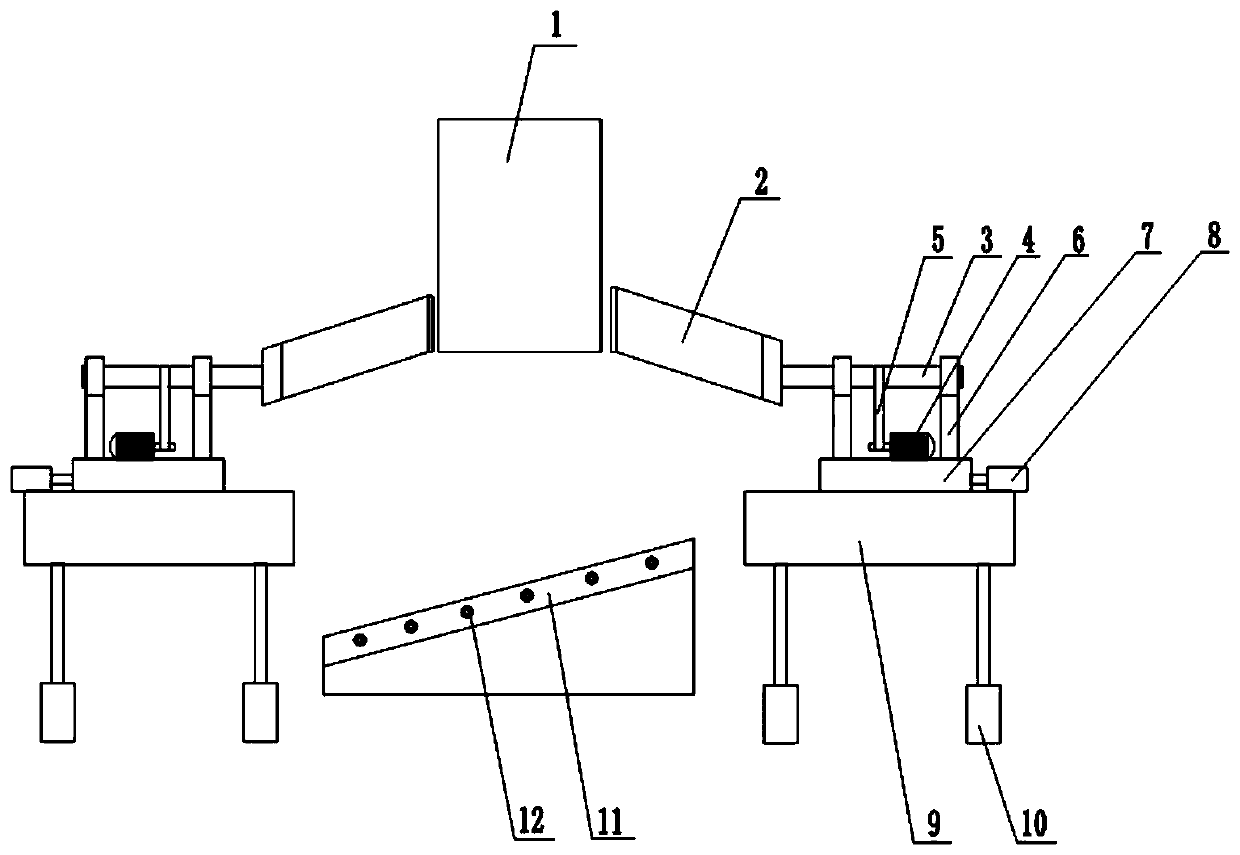

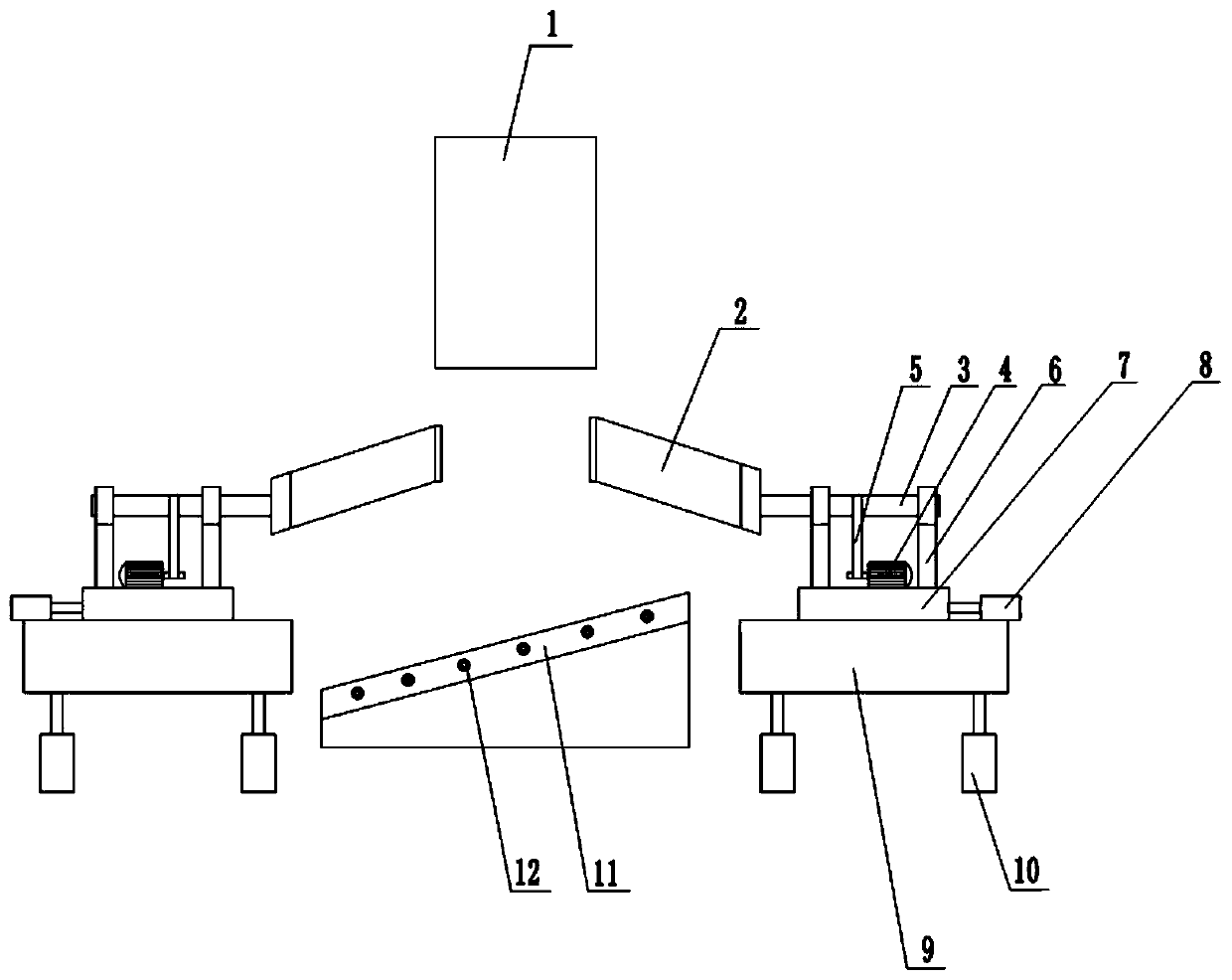

[0036] Such as figure 1 As shown, the construction waste grading treatment device of this embodiment includes a crushing mechanism, a grading and screening mechanism and a water washing mechanism arranged in sequence from top to bottom.

[0037] The crushing mechanism includes a crusher 1. The top of the crusher 1 is provided with a feed inlet, and the bottom of the side is oppositely provided with two discharge ports. The side wall of the crusher 1 is provided with an annular groove surrounding the discharge ports.

[0038] The grading and screening mechanism includes two lifting seats 9, and the lifting seats 9 are all connected with a lifting hydraulic cylinder 10 for driving its vertical movement. The lifting base 9 is provided with a movable base 7 which can move laterally, and a docking hydraulic cylinder 8 is fixed on the lifting base 9 , and the output rod of the docking hydraulic cylinder 8 is fixedly connected with the moving base 7 . Two vertical support columns 6 ...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that: Figure 10 As shown, in this embodiment, a reinforcing member is connected between the rotating shaft 3 and the screening cylinder 2, and the reinforcing member includes a fastening sleeve 13 fixedly sleeved on the screening cylinder 2, a fixed rod 15 fixed on the rotating shaft 3 and a fixed The reinforcing rod 14 connected between the fastening sleeve 13 and the fixing rod 15 . Since there is a certain angle between the rotating shaft 3 and the screening cylinder 2, when the two screening cylinders 2 are separated, the screening cylinder 2 is in a cantilever state, and the rotating shaft 3 is under a large force, and the reinforcement can play a role in strengthening and improving the rotating shaft. 3, and the fastening sleeve 13 can also play a fastening role to reduce the deformation of the screening cylinder 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com