Damp-proof anti-cracking composite wooden door and preparation method thereof

A wooden door and anti-cracking technology, which is applied in the direction of wooden layered products, chemical instruments and methods, door leaves, etc., can solve the problems of poor moisture-proof and crack-proof performance, easy deformation, and high production cost, so as to improve the moisture-proof and crack-proof performance, improve Structural strength, effect of improving sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

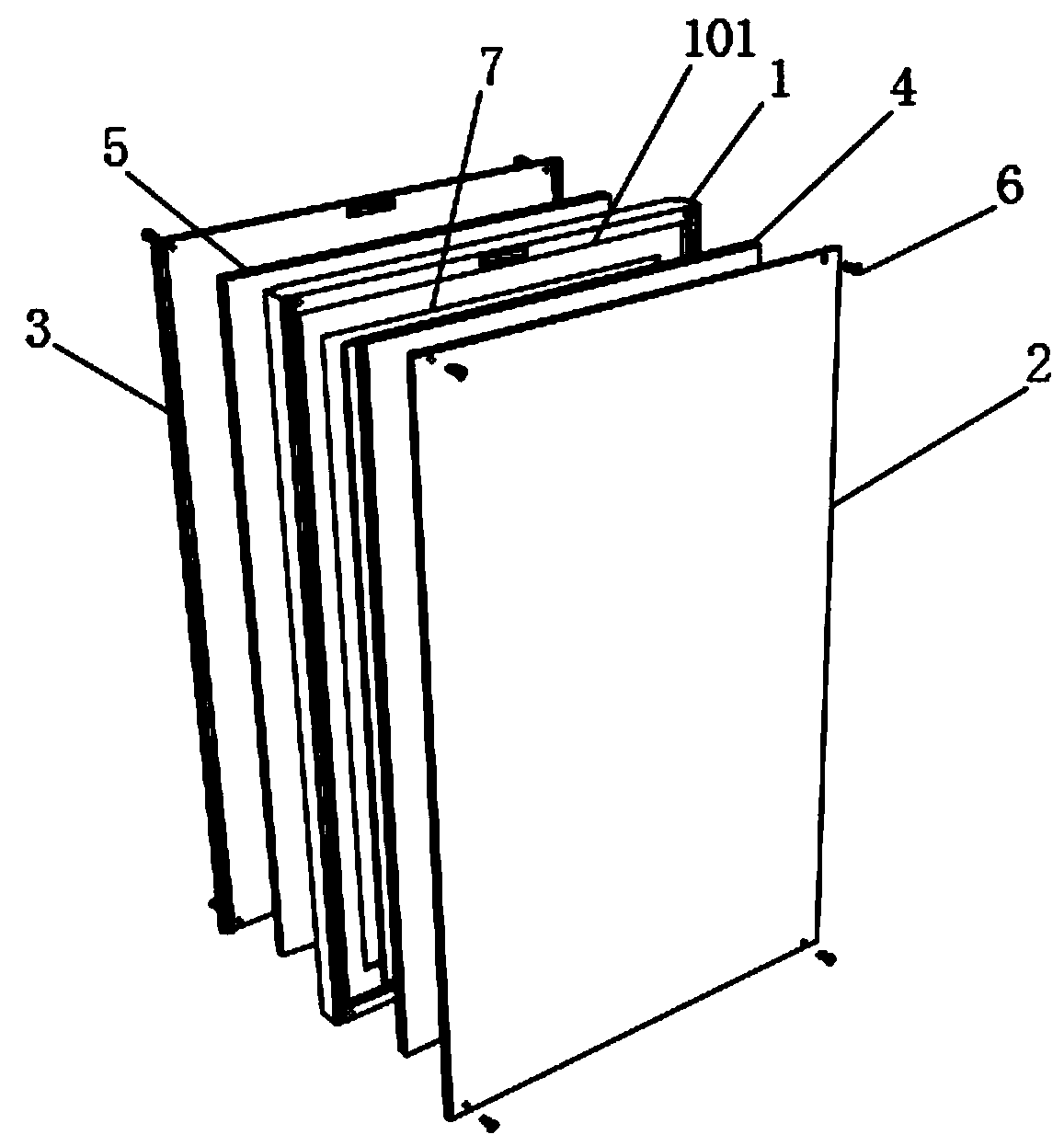

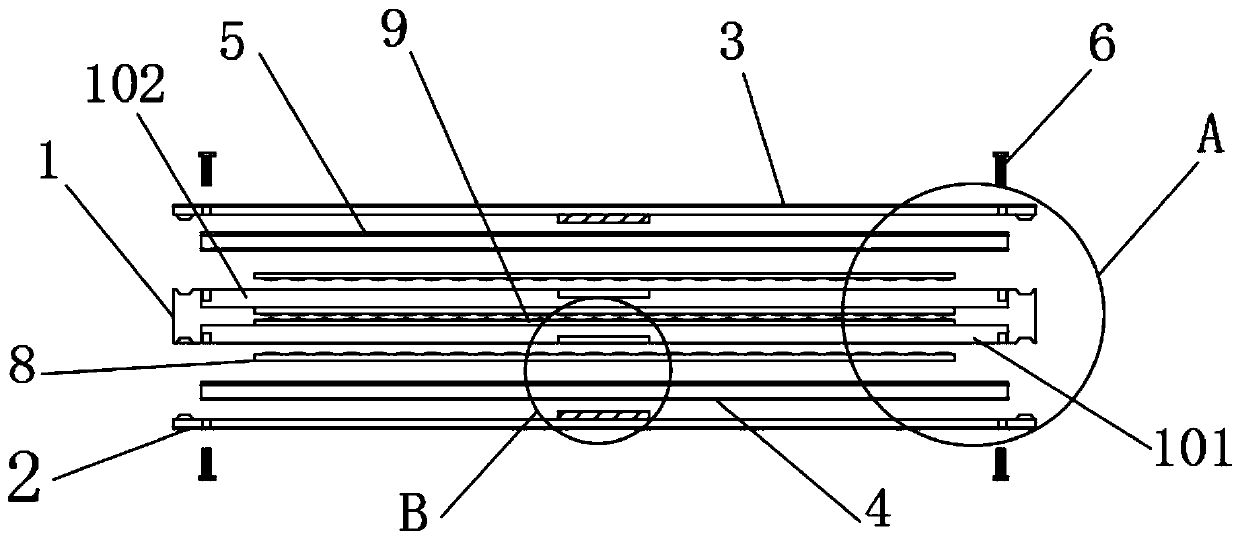

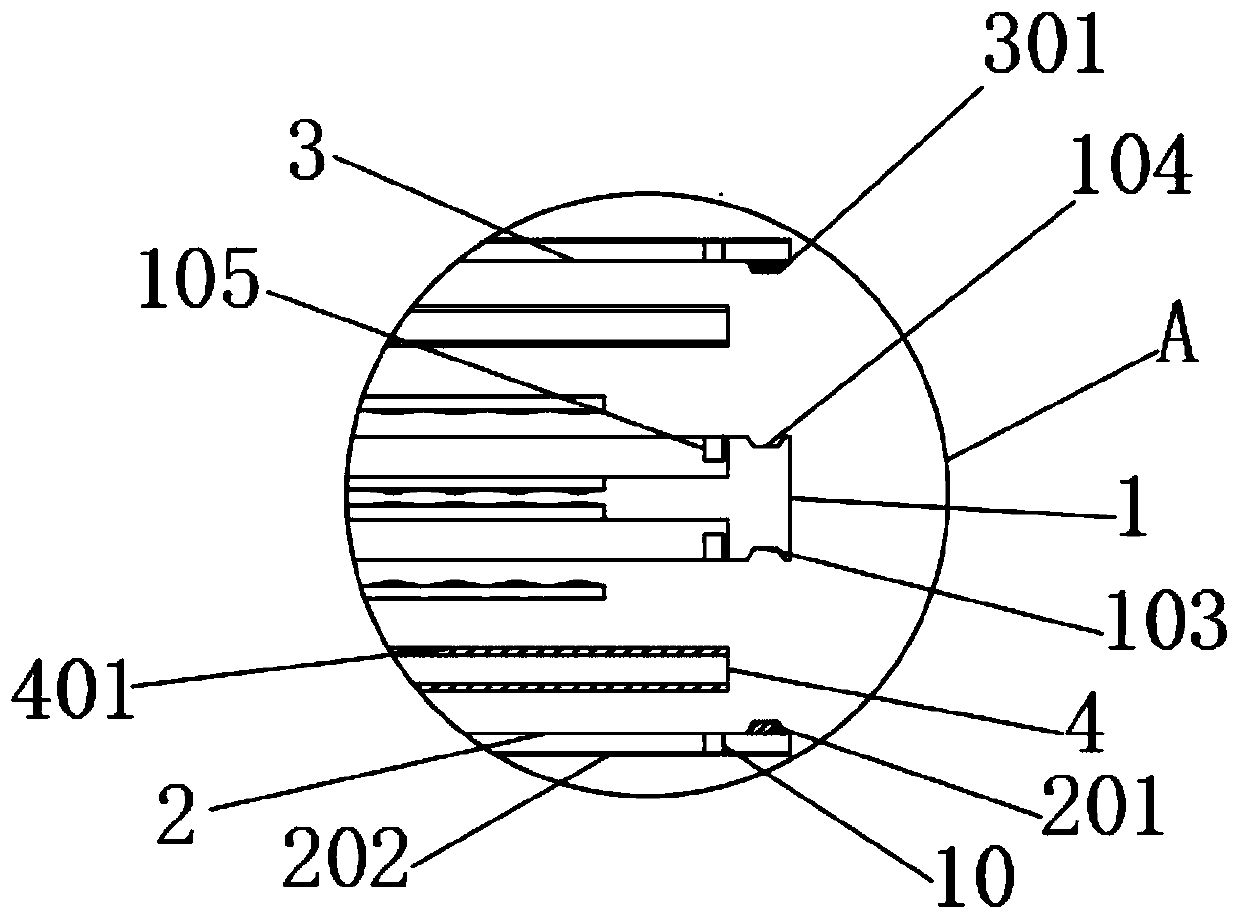

[0031] according to Figure 1-6 , the present invention provides a technical solution: a moisture-proof and crack-proof composite wooden door, including a wooden door panel body, a first assembly groove is opened on the outer surface of the wooden door panel body, and a second assembly groove is opened on the inner surface of the wooden door panel body. Assembling grooves, the inside of the first assembly groove is provided with a first anti-crack layer, the inside of the second assembly groove is provided with a second anti-crack layer, the first assembly groove and the second The inner surface of the assembly groove is provided with a sound insulation board groove, the inner side of the sound insulation board groove is provided with a sound insulation board layer, and the two sides of the wooden door panel body are symmetrically provided with two positioning grooves. The front side is provided with a decorative outer panel, and the inner side of the wooden door panel body is...

Embodiment 2

[0037] A method for preparing a moisture-proof and crack-proof composite wooden door, comprising the following steps,

[0038] Sp1: Select wooden boards to make wooden door panel body, decorative outer panel, decorative inner panel, first anti-crack layer and second anti-crack layer, and set up first assembly groove and second assembly groove on the wooden door panel body , opening a sound insulation board groove on the inner surface of the first assembly groove and the second assembly groove;

[0039] Sp2: Select the rubber sheet to make the sound insulation board layer and the reinforcement convex body, set up a reinforcement groove on the inner surface of the sound insulation board groove, insert the reinforcement convex body into the reinforcement groove, and use glue to bond the sound insulation board layer to the sound insulation board In the plate groove;

[0040]Sp3: Use sandpaper to polish the surfaces on both sides of the first anti-crack layer and the second anti-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com